Profiled beams are a popular choice for the construction of private houses. The material is really environmentally friendly, affordable, warm. However, when choosing and buying a profiled bar, its moisture is very important! Our tips site will tell you about the choice of a microwave drying bar.

The portal wrote in detail about the advantages and disadvantages of a profiled bar for the construction of a private house. We also talked about the features of building a house from this material. Recall that, unlike the more expensive glued laminated timber, profiled timber needs preliminary drying..

This is due to the peculiarities of the manufacturing technology. Glued laminated timber consists of pre-dried lamellas, which are oriented with fibers in different directions and fastened together. Therefore, it is not necessary to dry the material additionally. The profiled timber is, in fact, a piece of the core of the trunk. Its natural moisture content will be 50–80%. Building a house from such material is fraught with very serious consequences – twisting, warping, cracking! Moisture needs to be removed to 10-15%.

How is profiled timber usually dried? In an atmospheric, natural way, left under awnings or in an open warehouse. This is a gentle but very long lasting option. To achieve the optimal moisture content, the timber will take at least a year, and preferably two. In addition, manufacturers dry the timber in convection drying chambers. It takes two months for a billet with a section of 200×200 millimeters to reach a moisture content of 15% along the entire depth of the bar. Therefore, manufacturers often do not meet this period, offering supposedly dry timber, which in fact remains wet inside..

Microwave wood drying appeared relatively recently – in 2007. This is a huge microwave oven that only takes a couple of days to dry solid wood.

The advantages of a profiled bar in a microwave chamber are many:

- The most effective option. Humidity at the level of 12-18% is reached within a day.

- Cracking of wood is excluded, because the water that is inside the workpiece is heated.

- During processing, all bacteria, beetles, wood pests and their larvae, fungi and mold are killed.

- Complete environmental friendliness of the material, no glue, no chemical treatment.

- Dry profiled timber is cheaper than glued.

- High-quality dried material practically does not shrink; you can immediately install windows and doors in the house. In general, according to experts, it usually takes only three months from the beginning of construction of a house from dry profiled timber to housewarming..

- All parts are lightweight, with clear geometry, easy to build and fit to each other.

All of the above advantages are only for a really dry profiled bar that has passed through a microwave chamber. How to distinguish it from low-quality, under-dried material? This can be done by a non-professional, an ordinary buyer, a future home owner:

- Make sure that the production site does have a microwave camera. Yes, just ask the supplier to show you the production, the camera itself. If you are told that the drying is in another place or they refuse to let you into the workshop, there is a risk of buying a dried, low-quality material, the walls of which will shrink.

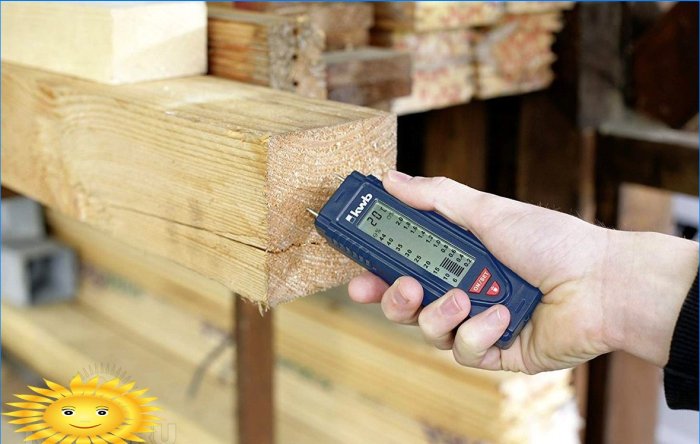

- Take with you a hygrometer, moisture meter. It is a useful and easy-to-use device that will accurately indicate the percentage of wood moisture. To check the moisture content throughout the depth of the log, use needle hygrometers that penetrate through the layers of wood to the very core.

- Assess the quality of the profile, grooves on the timber. If they were cut in wet wood, in any case characteristic roughness will remain..

- Just weigh a piece of timber with the simplest steelyard, cantor. A half-meter cut of a dry bar will weigh about 5 kilograms, and a wet one – at least 12 kilograms. The difference will be immediately apparent. The drier the timber, the lighter it is.

It is not easy to choose a high-quality microwave-drying profiled timber. There are enough unscrupulous manufacturers who pass off dried material for it. Following our advice, you can make sure of the high-quality drying of the profiled timber and build a warm house without the risk of problems with the walls..

Choosing a profiled bar of microwave drying

This post discusses the advantages of using a profiled bar for microwave drying. It offers distinct advantages compared to other types of drying, most notably a uniform drying rate that produces an end product with a consistently high quality. It also helps to reduce energy and labor costs, as well as product moisture levels. It eliminates special attention to product geometry or size, but does require some specific setup including proper flow rate, housing and filter arrangement, and heat-resistant material. A profiled bar is a great choice for those searching for a reliable and efficient way to dry their products.

Construction Materials

What are the advantages of choosing a profiled bar for microwave drying over other drying methods?