Recommendation points

- Advantages and Disadvantages of Composite Reinforcement

- Comparative characteristics of metal and composite reinforcement

- Caution: unscrupulous manufacturers

Composite reinforcement, which has appeared recently, has already managed to win the lion’s share of the construction market. In our article we will talk about what it consists of, how it differs from the traditional metal and where it is used, and also consider the most common myths.

Composite reinforcement was invented more than 30 years ago, but it has only become widespread in the last few years. Due to its technical and operational characteristics, such a material is quite capable of competing with classical steel reinforcing rods..

Reinforcement made of composites resembles steel in appearance, but it is made of fibers impregnated with special binders-hardeners. During the manufacturing process, ribs are formed on the rods or a sand coating is sprayed on to improve adhesion to concrete.

Several types of composite fibers are used for the production of reinforcement:

- Fiberglass with the addition of thermosetting resins – fiberglass reinforcement.

- Basalt fiber with the addition of resins – basalt plastic reinforcement.

- Carbon fiber (carbon) – carbon fiber reinforcement.

- Kevlar thread from DuPont – Kevlar reinforcement.

The last two types are used extremely rarely and mainly abroad. Compositions of hydrocarbon plastics and Kevlar were developed for use in the space and military industries, therefore they are characterized by both high strength and exorbitant price..

Civil engineering gives preference to fiberglass reinforcement, optimal in terms of cost and range of application.

Advantages and Disadvantages of Composite Reinforcement

The most vulnerable point of reinforced concrete products are metal reinforcing inserts that are prone to corrosion. Priming or the use of alloys does not completely solve the problem – sooner or later the metal rusts, destroying the concrete. Fiberglass reinforcement is not affected by aggressive media, which is just one of the many advantages:

- Tensile strength values exceed metal characteristics by almost three times.

- Composite reinforcement weighs 9-11 times less in equal strength.

- The material is not only inexpensive, but also allows you to significantly save on loading and transportation.

- Unlike metal, it does not form cold bridges, reducing heat loss.

- Durability and resistance to temperature changes.

- Has a coefficient of thermal expansion similar to that of concrete, which reduces the risk of defects and cracks.

- Fully dielectric and radio transparent.

- It can be made both in the form of rods and by winding into coils.

Tests also show the other side of the coin – the disadvantages of composite reinforcement:

- Low modulus of elasticity requires additional calculations when using such reinforcement in floor slabs.

- Low fire resistance is due to the fact that composites under the influence of high temperatures simply melt, turning into liquid.

- Inability to use welding.

- Inability to bend finished reinforcement on site.

It should be noted that all negative nuances are successfully solved by manufacturers and design engineers: during the construction of structures with a high load, special surveys and calculations are carried out, additional processing of concrete compositions and the reinforcement itself is used to increase heat resistance, all bent parts are manufactured in factories according to the projects.

Comparative characteristics of metal and composite reinforcement

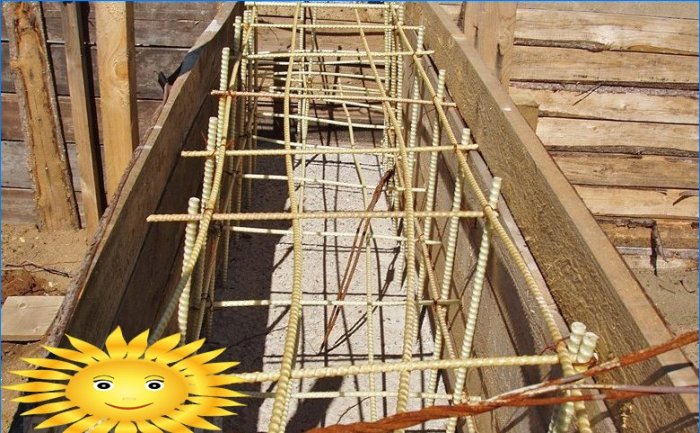

Subject to building codes, composite reinforcement can replace metal in all areas of application:

- Cottage construction: any kind of foundations and flexible connections for walls.

- Concrete structures in industrial buildings and multi-storey buildings.

- Production of heavy and lightweight concrete.

- Layered brickwork of various types.

- Bank protection and construction of coastal structures (not afraid of contact with water).

- Road paving (increases service life by one third).

- Creation of earthquake-resistant belts (recommended for use in areas of high vibration).

- Erection of monolithic buildings using fixed formwork.

- Electrification (lighting poles and power lines).

- Manufacturing of railway sleepers.

The characteristics of composite reinforcement are best presented in comparison with metal counterparts:

Metal fittings of class А-III (А400С) Fiberglass reinforcement Basalt plastic reinforcement Material Steel 35GS, 25G2S, etc.. Polymer bonded fiberglass with a diameter of 13-16 microns Basalt fiber with a diameter of 10-16 microns, bound by polymer Ultimate tensile strength, MPa 360 600-1200 (decreases with increasing diameter) 700-1300 (decreases with increasing diameter) Elastic modulus, MPa 200,000 45,000 60,000 Relative extension, % from 14 2.2 2.2 Density, t / m3 7.85 1.9 1.9 Corrosion resistance Rusts Corrosion-resistant material of the first group of chemical resistance Corrosion-resistant material of the first group of chemical resistance Thermal conductivity Yes not not Electrical conductivity Yes dielectric dielectric Profiles (diameter), mm 6-80 4-20, in perspective up to 60 4-20, in perspective up to 60 Length, m 6-12 (due to transportation requirements) Any size Any size When considering the feasibility of buying composite reinforcement and comparing its cost with metal, many pay attention only to the price of a running meter. ROCKBAR (manufacturer of fiberglass reinforcement), together with the University of Sheffield (UK), conducted comparative tests for tensile strength and strength of materials, which resulted in a table of equal strength replacement:

Composite rebar Steel reinforcement class А-III (А400С) Rebar diameter, mm Weight 1 rm. m, kg Number of meters per ton Cost r. m, rub. Rebar diameter, mm Weight 1 rm. m, kg Number of meters per ton Cost r. m, rub. 4 0.02 50,000 from 8.75 6 0.22 4504.5 from 11.10 five 0.03 33333 from 9.54 6 0.22 4504.5 from 11.10 6 0.04 25000 from 11.59 8 0.40 2531.7 from 16.50 7 0.06 16667 from 13.95 ten 0.62 1620.8 from 24.12 8 0.08 12500 from 17.27 12 0.89 1126.1 from 27.15 ten 0.20 5000 from 25.60 fourteen 1.21 826.5 from 39.12 12 0.23 4348 from 35.38 sixteen 1.58 632.9 from 49.90 fourteen 0.30 3333 from 48.42 20 2.00 404.9 from 77.05 sixteen 0.35 2857 from 61.88 22 2.47 335.6 from 93.10 18 0.43 2326 from 67.40 25 2.98 259.7 from 121,00 20 0.60 1667 from 84.10 28 4.83 207.0 from 151,00 Note: prices are taken from the official websites of manufacturers, in retail chains they may differ slightly upwards.

Simple calculations show that savings in the purchase of reinforcement made of composite materials can be up to 2 times compared to metal. Do not forget about other items of expenses:

- savings on delivery due to lightness and compactness;

- savings on loading and unloading – no need to hire workers;

- saving on consumables – fiberglass can be cut with wire cutters or bolt cutters;

- saving on trimmings – rebar in coils is cut to the required size without waste.

Caution: unscrupulous manufacturers

The implementation of innovations in the building materials market is always “squeaky”. Composite rebar is no exception. On the one hand, many large and small manufacturers have emerged. On the other hand, all factories operate according to their own specifications and try to lure the buyer with cunning tricks. Consider the most common myths.

Myth: Our products are better because we add secret ingredients (which also give an atypical bright color).

Fact: Pigmentation does not affect durability, its only plus is aesthetics. Moreover, an incorrectly selected pigment can impair performance. All specifications must be documented in test reports.

Myth: The more often the winding ribs are located, the stronger the reinforcement.

Fact: Winding ribs serve to increase adhesion to the concrete and do not in any way affect the breaking, strength and compression of the reinforcement. The only exception is the sand cover, which evenly distributes the load along the entire length of the bar.

Myth: Fiberglass reinforcement can be broken by hand, what kind of strength can we talk about?

Fact: Composite reinforcement works for longitudinal rather than transverse loads.

Unfortunately, there are no GOSTs for composite reinforcement yet. Therefore, choose products from trusted manufacturers, ask the seller for certificates and test reports, compare them with the above indicators and do not be fooled by the enticingly low cost..

What are the key advantages of composite rebar compared to traditional steel rebar, and how does it impact the durability and sustainability of buildings?