There are a great many building materials now. Among them there are familiar ones, familiar to everyone, and there are quite exotic ones. For example, peat blocks, which are rare, but have a number of advantages and are a good building material. Let’s talk about peat in construction in more detail.

What is peat? According to Wikipedia, it is a loose sedimentary rock. Peat is formed from the remnants of moss, which in the conditions of the swamp had time to decompose, but not completely. Peat consists of 50-60% of carbon. Peat bogs cover about 3% of the entire surface of our planet; it is a fairly widespread mineral. Why useful? Because the scope of application of peat is very large. And the characteristics deserve attention.

Of course, peat is most often used as a fertilizer in gardens, vegetable gardens, for adding indoor plants to the soil. Peat, as a natural fertilizer, is really very useful, and sometimes it is simply irreplaceable. In addition, we wrote how to make a peat dry closet for a summer residence, as well as about fuel briquettes from peat for heating a private house. However, the scope of application of this natural material is by no means limited to this..

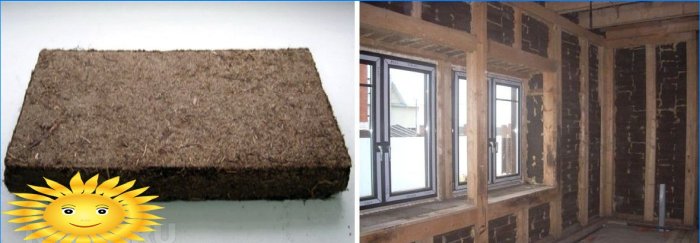

In construction, peat is primarily known as a sound and heat insulation material. For a long time, peat slabs have been used for this purpose, which outwardly look like mineral wool insulation. They are made from sphagnum peat with a decomposition rate of 5 to 12%, and a moisture level of 91–94%. Up to 30% of the board can be dry plant residues, including coarse wood fiber. If you add fire retardants to peat slabs, they will get fire-fighting properties. The addition of water repellents will give them water resistance, and antiseptics – the ability to resist biological threats, including mold and mildew.

Peat houses are not at all know-how. Thousands of years ago, this natural material was used for the construction of dwelling houses in Northern Europe. For example, in faraway Iceland, where there are many swamps, and therefore peat, but few trees. In Norway, at one time, green peat roofs were equipped. Icelandic peat dugouts and Norwegian peat roofs can still be seen, some are very well preserved, but already as a historical heritage, an interesting architectural object.

However, despite the antiquity of peat as a building material, the technologies of past centuries, of course, are outdated and are not used now. Yes, in some regions they build houses, mixing peat with sawdust, doing all the work in an artisanal way. But this is an exception. On an industrial scale, peat blocks began to be made recently, a new building material appeared.

For the production of peat blocks, of course, primarily peat itself is used, which is sieved and ground with water to the state of a binder. The fillers are shavings, sawdust, flax, chopped straw. Blocks are formed under a press and thoroughly dried, without firing.

Estonian scientists from the University of Tartu, for example, decided to combat the fragility of peat blocks by adding silica nanoparticles to oil shale. This made it possible to impart new properties to the material and to resolve the issue of slow solidification of peat blocks. Estonian scientists are confident that the resulting material, before it has time to solidify, will be an excellent option for printing houses on a 3D printer. Time will tell if this is so.

So far, scientists have identified the following advantages of peat blocks:

- Low weight. For example, a block of 510x250x88 millimeters in size will weigh no more than 4 kilograms, and a cubic meter of material will weigh from 250 kilograms.

- Low coefficient of thermal conductivity, which is in the range of 0.047-0.08 W / (m · ° С), makes the building material very warm.

- Sound insulation index at 53 dB, which is a good indicator.

- Environmentally friendly material based on natural ingredients.

- Peat is a natural adsorbent capable of cleaning the air from unpleasant odors and harmful substances.

- Mineral additives make peat blocks a fireproof material.

- Peat is breathable, so the walls will “breathe”.

- Compressive strength 10.7–12 kg / cm2.

Developers and manufacturers of modern peat blocks claim that such houses will stand for at least 75 years. As you can imagine, there is no evidence yet. But, judging by the Icelandic dugout houses, it is possible.

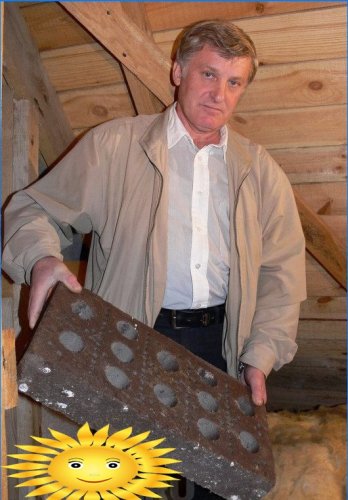

In our country, peat blocks are patented under the name “GeoKar”. This building material costs from 2750 rubles per cubic meter. Peat blocks of two types are produced – for interior partitions and external walls of the house, they differ externally by the presence of holes. The technology of masonry peat blocks is generally similar to the brick.

Use of peat in construction

Peat is increasingly being used in modern construction, offering a range of advantages over traditional construction materials. It provides natural insulation, preventing heat loss in colder climates, and its ability to absorb and retain moisture makes it ideal for moisture and mildew control. Peat is also lightweight and moldable, making it well suited for a variety of construction techniques. Combined with its affordability and availability, peat is fast becoming a popular choice for both home and commercial construction projects.

Construction Materials

Could you please provide more information on the use of peat in construction? I’m curious to know if it has any specific advantages or drawbacks compared to other materials. What types of construction projects commonly utilize peat, and what are the potential environmental impacts of using it?

Peat is an organic material formed from decomposed plant matter found in wetlands. It has been used in construction for centuries and offers some advantages. Peat is lightweight, easily excavated, and has good thermal insulation properties. It is commonly used for landscaping, horticulture, and as a fuel source. However, it also has drawbacks. Peat can shrink, settle, and decompose over time, leading to potential structural issues. Additionally, it is highly flammable and emits carbon dioxide when burned.

In construction, peat is primarily used for landscaping projects, such as creating gardens, golf courses, and sports fields. It is also sometimes utilized as a component in building materials like insulation and lightweight aggregates.

From an environmental perspective, peat extraction can have significant impacts. Harvesting peat disrupts wetland ecosystems, reduces biodiversity, and releases large amounts of carbon stored in the peatland. Drying peat for use emits greenhouse gases, contributing to global warming. Given these environmental concerns, sustainable alternatives to peat, like coconut coir or recycled organic materials, are increasingly preferred in construction projects.