Recommendation points

- Concealed waterproofing

- Reinforcing mixtures

- External waterproofing

- Hot bitumen

- Cold bituminous primers

- Water-soluble (aqueous) primers

In this article, you will find out what mixtures with a waterproofing effect are. We will tell you about different types of sealing compounds and provide a comparative analysis of the market price. The article will tell you about different types of primers and some methods of industrial waterproofing.

Protection against moisture is paramount when it comes to protecting structural elements. More damage than moisture is caused only by sudden changes in temperature. In this case, destruction and deformation occur due to the expansion of water in the material. The portal will tell you about popular waterproofing mixtures that are commercially available and are used privately without the involvement of special equipment and machines..

For each task, there is a specific class of waterproofing materials (GI materials), designed for specific conditions. By location, there are hidden and open waterproofing.

Concealed waterproofing

A protective water-repellent layer is applied between the finishing or preparation layers. Designed for indoor use during finishing work in bathrooms, saunas, swimming pools. The only function is to protect the base from leaking.

This effect is achieved by adding cellulose ether and dispersion powder to the finely ground cement mortar. These additives are conventionally called “compound”, they seal the solution in a chemical way. They are chemically active and make up 3–7% of the total mass. Depending on the amount of the compound in the mixture, it may have more or less reaction activity.

GI material with a large percentage (6–7%) of this additive is called “hydro-plug”. It hardens very quickly, despite direct contact with the flow of water..

Most dry “household” mixes can be divided into one- and two-component. Mixtures that only require the addition of water are considered to be one substance. This GI is applied between the layers of the base and finish on even, stable surfaces..

The two-component composition is recommended for moving or potentially moving parts – floors in panel and block houses over 30 years old or in seismic zones. The layer remains airtight, allowing stretching up to 5 mm. In the corners and at the joints of the walls and floor, a reinforcing fabric is necessarily used – non-woven or fiberglass (sometimes impregnated with resins).

Consumption of dry GI mixtures is usually from 1.5 to 2 kg / sq. m with a layer of 1 mm.

Dry mixes for hidden (internal) work

Name Manufacturer Packing, kg Packing price, rub. One-component “Hydrotex U” “Hydrotex”, St. Petersburg 25 1890 SILTEK V-30 Waterproofing SILTEK, Ukraine 25 730 SILTEK V-37 Hydraulic plug SILTEK, Ukraine 25 1450 GDS 300/500 “Mountain Khrustalnaya”, Krasnoyarsk 20 680 Ceresit CR 65 Ceresit, Russia / Germany 25 1050 “ALIT” GR-1 (“ALIT” GR-1n) “ALIT”, Chelyabinsk 25 900 “Hercules AQUA-STOP” “Hercules”, Novosibirsk 25 700 Two-component Reniment barralastic AUDAX, Germany 25 3000 SILTEK V-33 Elastic

SILTEK E-33 CompoundSILTEK, Ukraine 20

5L1740

1750Ceresit CR 166 Ceresit, Russia / Germany 24 1770 Baumacol Protect 2K Baumacol, Germany 20 1900 Ilmax 4620 aqua-stop flex ILMAX, Belarus 24 kg + 8 l 3200 KT Tron 10-2K KTTRON, Kazan 25 4400 Reinforcing mixtures

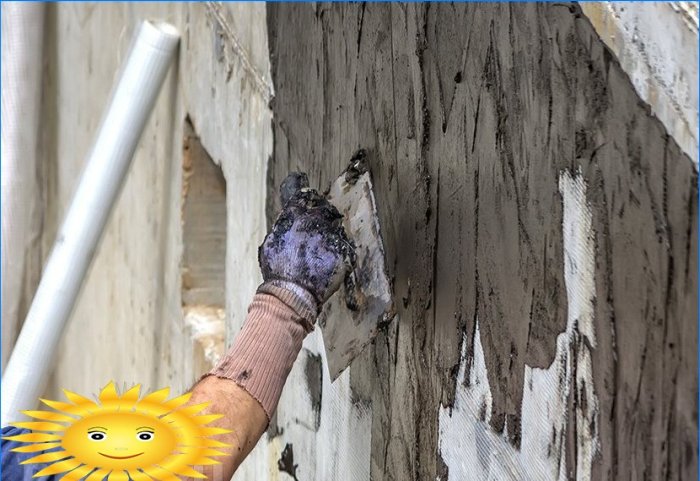

They are the above-described technical compositions, but with more resistant properties to atmospheric phenomena. They perform a combined function – waterproofing and an intermediate layer that connects insulation (stone wool, PPR) and decorative putty. The increased content of cellulose ether and the addition of fiber give these GI materials anti-vandal properties.

GI mixtures for outdoor use are used together with a reinforcing mesh, which keeps the composition from natural cracks arising from temperature changes.

Dry reinforcing mixtures for outdoor use

Name Manufacturer Packing, kg Packing price, rub. “LAKHTA” Waterproofing “LAKHTA”, Chelyabinsk 25 4750 “Penekrit” “PENETRON”, Russia 25 6300 CT Tron-6 KTTRON, Kazan 25 1250 Perfekta® “AQUASTOP” PERFEKTA, Balashikha 20 670 “Kalmatron” GI KALMATRON-SPb, Saint Petersburg 25 1900 “OSNOVIT T-61 Aquascrin” OSNOVIT, Moscow 0.5 147 “OSNOVIT Hardscreen T-63” OSNOVIT, Moscow 20 770 External waterproofing

Various primers are used for the operation of open areas and technical premises..

Primer – anti-corrosion paint for the protection of open structural elements, tanks, wells and tunnels in direct contact with water. Penetration depth – up to 1 mm. Has a technical appearance (usually black). According to the composition of the binder, it is divided into two main subspecies.

Hot bitumen

Technical resin, oil product. When heated, it passes from a solid to a liquid state of aggregation. Application is possible at a temperature of 110–160 ° C. Exceptionally resistant to the atmosphere and durable. Often serves as a vulcanizing adhesive for roofing material. After hardening, it is not pasted over or painted. Application requires compliance with safety regulations.

Cold bituminous primers

They consist of crude oil products (oil, fuel oil) bound by a volatile solvent (diesel fuel, kerosene). Extremely toxic, but have the maximum depth of penetration among cold formulations.

Water-soluble (aqueous) primers

Household mixes for coating and painting open areas of wood, concrete and steel structures. They consist of finely ground waste slag (pitch, ash and granulated slag) bound by water. Absolutely non-toxic, but have poor performance properties. In practice, open areas must be “refreshed” every two seasons (according to the instructions for 3-5 seasons). Aqueous primer is well suited for humid conditions, but washes out upon active contact with water (rain, drain).

The primer consumption is usually about 250-350 ml / sq. m per layer.

Waterproofing primers

Name Manufacturer Packing, kg Packing price, rub. Bituminous Primer Bituminous “Stroy Profi”, Moscow 20 765 Primer Bitumen PB TechBeton, Yekaterinburg sixteen 640 Bitumen primer ST “Grida”, Moscow region 16 (20 l) 1200 Bitumast PRIME “Bitumast”, St. Petersburg 20 1800 Bituminous primer “Stroy-ka”, Moscow region 17 1150 Aquatic Fixa Bitumfix ВС 2К FIXA, Turkey 24 2700 TechnoNIKOL No. 04 “TECHNONICOL”, Rostov-on-Don 20 1160 PAZ-Primer Pazkar, Israel 15 4000 The dry mixture first turns into a solution before application. Accordingly, the process of applying a cement-based GI can be called plastering. In industry, a special type of mortar waterproofing is used – gunning. Cement-sand mortar is supplied under pressure from a special “gun”. The particle velocity of the mixture is 80–100 m / s. Under such a pressure, the solution is compacted to such an extent that it does not absorb water after hardening..

There are more and more waterproofing methods every day, however, dry mixtures based on cement do not lose their relevance, firmly taking their place between the main and finishing layer. Here they have no competition, because in addition to moisture protection, the layer must ensure reliable adhesion of the entire “pie”. Convenience of storage allows transporting mixtures over long distances, and ease of use makes it possible to use them without special skills.

What are the key characteristics one should consider when selecting a waterproofing mixture? Additionally, could you provide some helpful tips on how to make an informed decision when choosing the right waterproofing solution?