Recommendation points

- Remote control goals

- Fuel type and operating modes

- Electric boilers

- Gas boiler houses

- Solid fuel heating control

- Special functions

Today we will talk about the possibility of automating the control of heating boilers in a country house. Indeed, today there is no problem to provide remote dispatching of household systems, including heating, providing savings and a high level of comfort.

Remote control goals

How often does the average resident of a country house come to a heating boiler? If it is a gas or electric unit, then minimal attention is paid to it. Thanks to modern automation devices, autonomous operation of the boiler is possible for a very, very long time. Only in severe frosts do you want to turn on the light in order to feel this pleasant contrast even more: there is snow and wind outside the window, and the house is warm and cozy. But remote dispatching exists, so what tasks does it solve??

To begin with, there are two heating modes: economical and comfortable. If the tenants of the house are absent for 10-12 hours a day, why maintain the optimal 23 ° C, if you can set the temperature sufficient for the safety of indoor plants and pets? And if the system will operate in a saving mode during the absence of the owners, how to ensure a quick access to the rated power so as not to return to the half-cooled house every time? Timing control can be used, of course, but it’s rare to have a crisp and consistent schedule. So, the first goal of remote heating control is to quickly change the heating power.

Another aspect is the stability of the system. No matter how reliable and high-quality the boiler equipment is, the probability of an accident is still not zero. A drop in pressure, a stop in circulation, gas leaks – all of these are potentially quite frightening phenomena. If the boiler room is left unattended for a long time, then remote dispatching provides its second important function – monitoring the system’s performance and notifying the user about malfunctions. Well, the third function is the ability to remotely troubleshoot or prevent the consequences of an accident.

Fuel type and operating modes

Electronics provides a huge range of solutions of various levels of complexity, including those controlled over long distances. However, there is a big difference in what type of heating system you have to deal with, this directly determines the completeness and cost of the equipment..

The easiest way to control electric boilers: one or more heating elements can be switched by a simple contact or solid-state relay. Additional commutation can be used to control forced circulation devices. Neither gas leaks nor damping of the solid fuel combustion chamber can occur.

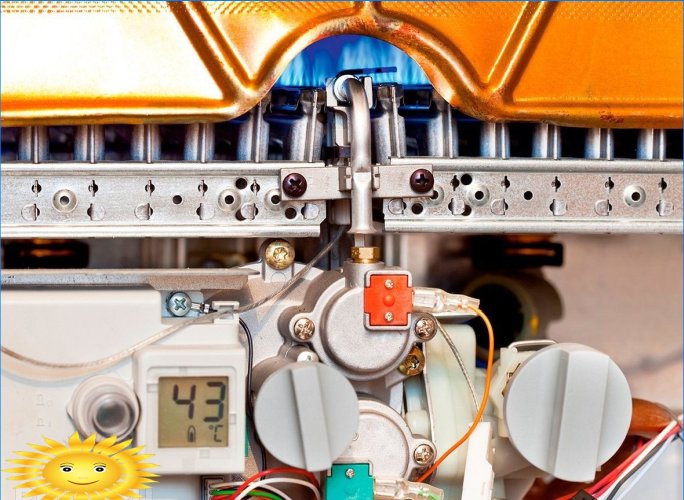

If gas is selected as the source of energy for heating, the boiler room is classified as a hazardous facility. Backdraft can extinguish the burner, which faulty automation will safely ignore. Remote control will allow you to turn off the gas supply or re-ignite the boiler, and if this is not possible, drain the water from the system to prevent it from freezing.

It is more difficult than others to manage solid fuel heating systems. It requires control over the automatic supply of fuel, it is extremely important to maintain a constant circulation so that the coolant does not boil. But in this regard, dispatching devices cope with a bang: in the end, everything is controlled by electromechanical devices, and it is very easy to intervene in their work remotely.

Electric boilers

Remote control of an electric boiler is one of the most budgetary projects. Depending on the configuration and operating modes of the system, several options can be offered.

For heating without power control, where the problem of freezing is not relevant, that is, for antifreeze-based hydraulic systems, as well as air and convection systems. In such cases, all tasks are solved primitively – a “smart” socket that can receive GSM messages (Brownie, Sokol). The price of the issue is on average from 300 to 1000 rubles, the difference in cost is due to both differences in quality and switched load, and the presence of additional functions. For example, an outlet can have a built-in thermostat or timer, as well as an independent power source. Some models have the ability to connect to mobile devices for easier customization of operating modes. Most of the products provide feedback to the user, in particular, such outlets are able to notify about the correct execution of the command or the absence of electricity at the facility..

For multi-stage boilers and other heating devices with several active elements, several outlets can be used, but it is better to install one multi-channel (Elgato, Polygator) – the so-called rebooter. These devices are available in a wide variety of configurations – both conventional plug multipliers and DIN rail mounting. The principle of operation is the same: remote load control by sending SMS with an instruction code or a call. Here it is already possible to implement quite interesting algorithms of work, such as turning on an additional heating circuit with a separate thermal control system. It will be enough only to make small changes to the boiler electrical wiring diagram by connecting separate heating elements to different channels.

Gas boiler houses

Unlike electric ones, gas heating systems require not only receiving commands from the remote dispatcher, but also high-quality feedback. Since direct control of a high load is not required, the solutions of the class described above are not quite applicable. The best way out of the situation would be to use a modular switch with 3-4 contact groups, controlled by one of the wired interfaces (RS-232, 1-wire, etc.). Messages can be transmitted both via the GSM channel and through communication with a PC installed at the facility. Usually, for the purpose of increased reliability, the main and backup channels are organized..

The price range for gas boiler control systems is incredibly wide. In the lower price segment, there are devices from budget Ksitalov for 7-8 thousand rubles to more friendly to an unprepared user Segnetics for 15-20 thousand rubles. Domestic automation systems OWEN belong to the middle link; a set of devices can cost 20-30 thousand rubles. The most complex systems costing more than 50-70 thousand rubles are used in modular boiler houses for general use: on the one hand, dispatching notifies the service organization about the status of the system, on the other hand, users control individual parts of the collector unit at their discretion. Such solutions are not just a set of devices “out of the box”, manufacturers of equipment for boiler rooms such as POCC and Viessman work in this category, providing the consumer with a comprehensive project and carrying out installation, configuration and maintenance of the system by qualified personnel.

In essence, such devices are conventional signaling units with 6 to 20 monitoring zones and are capable of controlling 3-5 groups of dry contacts. There are two popular architectures of this kind of systems. Xital, for example, is a specialized boiler automation unit, which was originally designed to connect standard temperature sensors, gas contamination, smoke and flame detectors. In turn, systems such as Segnetics and OWEN are based on freely programmable controllers, which can be supplemented with communication devices and individual switching units. Their main feature is the ability to connect atypical sensors and control actuators of completely different types..

The main difference between the representatives of the latter group is in the presence of a convenient user interface: Segnetics is easily configured when connected to a PC or mobile devices, but OWEN complexes require a more serious engineering approach, including writing your own firmware in high-level programming languages. What choice to make for yourself depends on the complexity of the boiler unit and the boiler room piping. So, the simplest Xital block will be enough for full control over the operation of parapet and chimney boilers of low power (up to 40 kW), while OWEN is used in boiler rooms with parallel connection of units, or in centralized air heating and air conditioning systems.

Solid fuel heating control

The freely configurable control systems are ideal for solid fuel boilers and plants associated with biogas generation. The reason for this is obvious: such boiler rooms were originally designed to work in the presence of an operator and, as a rule, have an individual scheme for setting operating modes..

So, for the simplest solid fuel boiler, it is necessary to adjust the inflow and draft, control the temperature not only of the air in the room, but also of the coolant at the inlet and outlet of the boiler. Additionally, you should carefully monitor the operation of the circulation system by differential measurement of the pressures at the inlet and outlet of the recirculation unit. The inclusion of gas analyzers in the complex will also not be superfluous; in addition, it is worth considering the temperature of the combustion products. The secondary function of such dispatching systems can be called the provision of economical fuel consumption and optimal combustion modes, depending on the desired temperature and weather outside the window..

It is important to emphasize that full direct control over each unit of the boiler room will be superfluous for the average user. Therefore, to control solid fuel heating, complexes of two nodes are used: receiving commands provided by a GSM receiver or an Internet router, as well as a software and computing complex, which is configured once, and then ensures the correct interpretation of commands.

The additional complexity is introduced by the variety of actuators. Servo drives are used to control valves and gates, the performance of smoke exhausters and blowing fans and circulation pumps is usually controlled by a frequency converter or PWM. The complex architecture of the system obliges to order not separate automation modules, but a complete set of equipment. However, most suppliers of such systems provide this kind of services for a very reasonable price: typical projects are about 30-40 thousand rubles, including the cost of equipment, but the automation of an atypical boiler house with automatic fuel supply can cost more than 50 thousand rubles with a power of up to 100 kW.

Special functions

As a result, we will analyze what functions of dispatching systems are strictly required, what is the logic of action of such devices and what additional possibilities exist. So, when choosing automation with remote control, you should give preference to those products that provide the following functions:

- availability of a backup communication channel;

- watchdog timer that reboots the system when it hangs;

- polling of individual control zones;

- remote control of contact groups and their sufficient number;

- system state change notification;

- feedback, sending messages about the acceptance and execution of commands.

Additional capabilities of the supervisor module should be determined in accordance with the characteristics of the heating system device. So, for liquid heating systems, it is recommended to have protection against leaks: humidity sensors and an electronic pressure gauge capable of recording a prolonged pressure drop. For open heating systems, control of the liquid level in the expansion tank is desirable..

Particular attention should be paid to monitoring the operation of forced circulation devices. If the boiler is technically unable to turn off the heating when the critical temperature is reached, the only evidence of overheating can be the readings of the temperature sensor on the supply pipe, which the control unit receives with a significant delay. In such cases, it is necessary to remotely stop heating by stopping the fuel or air supply, and if there is a risk of freezing of the coolant, drain it.

For remote control systems, it is preferable to have an automatic response to abnormal sensor readings. For example, the automation itself must adjust the circulation rate depending on the temperature of the coolant in the supply and return, while the user should only receive notifications about critical conditions. In general, we can say that the most important benefit from the use of the systems we have considered is the timely receipt of information about breakdowns, which allows not only to take personal part in the elimination of the accident as quickly as possible, but also to purchase a replacement for faulty components or call a specialist if necessary.

Device type Control method Functions Price, rub Smart sockets TP-LINK HS100 Wi-Fi Internet Remote on / off, timer 2188-2290 Smart GSM socket SC1-GSM GSM Timer, remote on / off 2390 Telemetrics GSM-Socket T4 GSM Remote on / off 5990 SimPal T4 GSM Sensor triggering (thermometer) 3600 Controllers XITAL GSM-T GSM 2 temperature sensors, 3 independent relays, up to 12 control zones 8640-9090 GSM Device SOKOL GC-5 GSM 5 channels of load control up to 10A 3250 EctoControl Wi-Fi / GSM Up to 67 sensors can be connected from 9900 ARIES TRM132M Wi-Fi / GSM Temperature control in the circuit and in the room, a set of preset modes, overheating protection, diagnostics of emergency situations 14300

What are the most reliable devices available for remote control and maintenance of temperature in a house? How easy are they to install and use? Are there any specific features or brands that you would recommend for efficient temperature control?

What are some of the best devices available for remotely controlling and maintaining the temperature in a house? Are there any specific features that I should look for in such devices to ensure maximum efficiency and convenience? How easy is it to set up and use these devices?