Recommendation points

- Appointment

- Types of circulation pumps. Choice

- Installation of the pump. How to avoid mistakes

- Practical advice

A circulation pump is a device that allows you to intensify the process of circulation of the coolant through heating devices. Installing a circulation pump often allows you to solve problems in existing heating systems, with their insufficient efficiency.

Appointment

Recently, circulation pumps have become very popular for heating systems. Circulation pumps are used in home heating systems for forced circulation of the coolant, and they are also used to create warm water floors.

Types of circulation pumps. Choice

Circulation pumps are available with dry and wet rotor. Pumps of the first type are mainly used in stationary boiler houses of high power. Wet rotor pumps – the rotor of the electric motor which rotates in the water. They have a number of advantages: quiet operation, lower power consumption, and do not require maintenance. Such advantages of these pumps have made it possible to successfully use them in heating systems for individual houses..

The main parameters of circulating pumps with a wet rotor are their supply (amount of pumped water per hour), head (to what height the pump is able to lift water) and connection dimensions in millimeters. The choice of a circulation pump comes down to determining the required flow in cubic meters per hour. But not only. The issue is solved by calculations, however, for most cases of individual houses and cottages, pumps 25/60 or 32/60 can be recommended. This is true, since most home heating systems are made of polypropylene pipes with a diameter of 25 or 32 mm. And it has been experimentally found that, according to the flow-pressure characteristics of the pumps, the pressure is 60 m of water. Art. (meters of water column) is more than enough, both to completely fill the system and to create the required flow (circulation intensity).

Installation of the pump. How to avoid mistakes

The installation of a circulation pump consists in installing it in a certain place on the heating system pipeline. There are options here. Consider the installation of a pump using the example of its installation on polypropylene pipes. This method differs from installation on steel pipes only in installation work (tie-in, threading), the assembly scheme of the assembly remains the same.

Required materials and tools:

- polypropylene pipes of the appropriate diameter;

- necessary fittings (couplings, adapters, corners, tees);

- shut-off valves (taps);

- the pump itself;

- a set of welding equipment for polypropylene pipes;

- flax or FUM tape (for sealing threaded connections);

- pipe wrench, adjustable wrench, pliers.

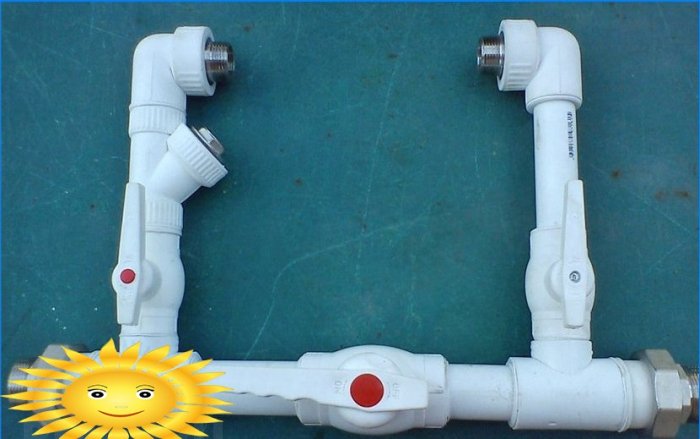

The pump must be installed using a bypass. This means that the main line of the heating system pipeline is preserved, and the pump cuts in parallel to it. This line is first assembled. It is necessary to take a special polypropylene fitting to switch from a metal pump to a polypropylene pipe: a combined coupling with an external thread corresponding to the connecting dimensions of the pump. It should be installed on the pump using tape or FUM tape. This should be done on each side of the pump..

Now we weld to both existing couplings on the tap (polypropylene ball valve). The valve must be sized to match the coupling. Typically this knot is made using a 90 degree angle. The angle can be set both between the coupling and the crane, and after the crane. Having performed this work on both sides of the pump, we get that same parallel line – the bypass. Having measured the distance between the two extreme points of the structure, including the pump, couplings, two cranes and two corners, we obtain the overall size of the bypass with the pump.

1 – polypropylene corner; 2 – ball valve; 3 – circulation pump; 4 – coarse filter; 5 – ball valve; 6 – polypropylene tee

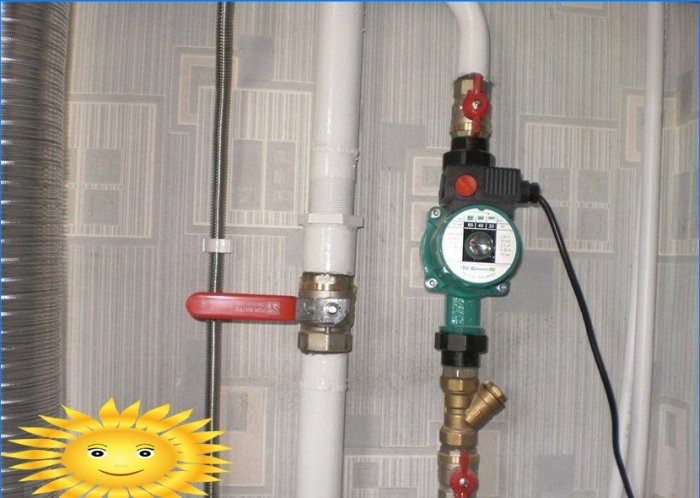

Next, you need to decide on the location of the pump. In front of the boiler in the direction of movement of the coolant, or after. The most correct installation would be in front of the boiler, on the return pipe of the system. It is possible to install a pump after the boiler, on the supply pipe, but less effective, and is used only when it is not possible to install a circulation pump on the return pipe.

Knowing the overall size of the bypass, it is necessary to mark the places where the polypropylene tees are inserted into the pipeline. We cut out a section of the return pipeline according to the marks, weld tees to the ends of the pipes of the heating system (their size should match the size of the return pipeline, and the branch of the tees should match the dimensions of the pipe and bypass fitting). A crane is installed between the tees, which should not narrow the dimensions of the pipeline. Now we weld a bypass on the branches of the tees. The dimensions of the pipe sections between the main elements of the assembly are selected based on local conditions, taking into account aesthetics and ease of execution.

Practical advice

When installing the pump, pay attention to the fact that the axis of the pump electric motor is located strictly horizontal, the possible options are always well described in the documentation for the pump.

Winding tape or FUM tape on the thread should be clockwise, looking at the thread cut. For a better seal, it is recommended to first wind a little flax, and then 5-6 turns of FUM tape.

It is important to think about how the entire assembly with the pump will look like in order to take into account the various possibilities and not be mistaken.

When working with polypropylene pipes, it is imperative to provide for the need to mount the pump to the wall or floor. Most often, metal clamps with a hairpin are used for this..

Connecting the pump to the electrical network is easy. For some manufacturers, for this it is enough to insert the standard plug of the electrical cord into the outlet. But more often, you need to make a cord with a plug yourself (we buy a piece of an electric three-core cord and a plug). Opening the pump cover (screw for a Phillips screwdriver), wind the cord inside and connect to the N, L, and ground terminals. Do not confuse the contacts “zero” and “ground”!

Before starting the pump for the first time, bleed the pump after filling the system with water. To do this, slightly unscrew the plug on its body until water appears, and then tighten it tightly.

Can you provide a step-by-step guide on how to install a circulation pump in a heating system?

I’m quite curious about the process of installing a circulation pump in a heating system. Could someone please explain the necessary steps involved? Is it a complex task or can it be done by someone with basic plumbing knowledge? Thank you!