Recommendation points

- Types of fuel for solid fuel boilers

- Benefits of briquettes and pellets

- Energy efficiency

- Fuel storage rules

- Use of briquettes and pellets

The sleds need to be prepared in the summer, as well as the fuel supply for heating. In this article, we will talk about the types of fuel for pyrolysis boilers, we will describe the advantages of pelletized and briquetted materials, how to store them and the use of such fuel in heating boilers of various designs.

There are a large number of types of solid fuels, as well as options for re-equipping boiler houses for different fuels. And yet, the factor of the greatest availability is considered the main argument when choosing, but is this approach really rational?

Types of fuel for solid fuel boilers

Most fuels are based on vegetable raw materials – cellulose. Wood is almost 100% wood and is considered a natural source of combustible carbon. Coal and brown coal, as well as peat, consist of plant remains that have undergone a number of natural transformations that have increased the density, and hence the content of combustible components per unit volume. A similar principle applies to the creation of artificial fuel – pellets or briquettes..

It is customary to evaluate different types of fuel according to a number of criteria, among which the most interesting is specific calorific value, otherwise referred to as calorific value. Indeed, what could be more important than the amount of heat that can be obtained from different types of fuel? But solid fuel is very specific in use, the role is also played by the amount of ash formed during combustion and the gas composition of combustion products, ease of storage, use and the main indicator – price.

Firewood and peat are considered to be the cheapest fuel, and in many regions of Russia they are completely free: no one bothers to go to the forest or peat bog once a year and stock up on fuel for future use. Bituminous and brown coal generate a large amount of energy during combustion and have a long burning time. It is necessary to throw a new portion of fuel into the firebox 2-3 times less often than firewood, and this is quite convenient.

At the same time, all types of coal, when burned, leave behind up to 40% of ash from the original mass, which means that you need a place for its seasonal storage and a well-thought-out method of disposal. The smoke from coal combustion is quite caustic, contains a large amount of sulfur, due to which a very unpleasant smell appears in the room. Soot and solid particles settle on the chimney and ducts, leading to their constant pollution and reduced draft.

But not only coal can clog the chimney. Firewood, due to their high humidity, emit a certain amount of steam during combustion, which interacts with smoke and forms tar, and it is much more difficult to clean pipes and channels from it. Due to the open storage method, coal also has a high humidity, and although this does not so much affect the pollution of the chimney, the calorific value is somewhat reduced.

Benefits of briquettes and pellets

Eurowood – briquetted and pelleted fuel – is obtained as a result of processing waste from sawmills and agricultural enterprises or other plant materials. Everything is used: from sawdust and tree branches to sunflower husks. The initial components are pre-crushed and dried, then crushed to a very fine fraction and pressed in the form of logs or granules.

In terms of composition, briquettes are almost indistinguishable from pellets; bulk fuel was developed for systems of its automatic feeding into the furnace. Artificial fuel has a density much higher than that of wood and peat and slightly more than that of brown coal. The moisture content in pellets is almost three times lower than that of naturally dried wood.

During the combustion of pellets and briquettes, only carbon dioxide and a small amount of soot are formed, up to half of which immediately decomposes due to the high combustion temperature and lack of moisture. There is a myth that briquetted fuel is dangerous due to the combustion products of the glue. However, no additional binders are used in the manufacture: wood itself releases sticky lignin at high pressure and temperature. With this treatment, initial pyrolysis processes also occur, partially activating cellulose, this makes the combustion of briquettes more “clean”.

Energy efficiency

Fuel from different sources with different storage conditions may have significantly different indicators, however, to compare energy efficiency, a table with averaged values is sufficient:

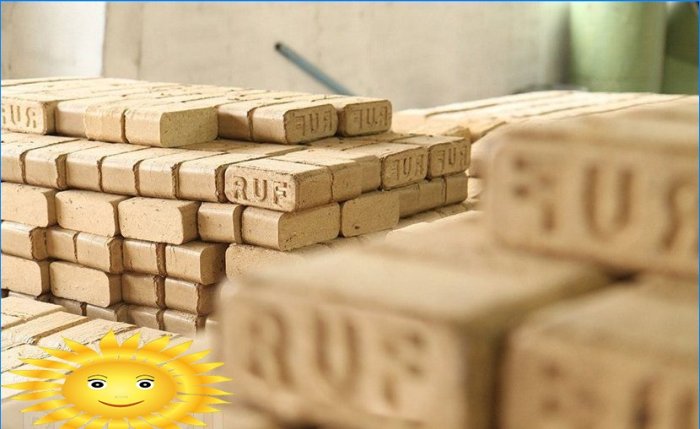

Fuel Bulk density, kg / m3 Humidity Caloric content, kcal / kg Ash content Burning time Solid wood 350-600 20-25% 2800-3400 2.4-3.2% 1-1.5 h Peat 400-600 28-30% 2600-2800 5-10% 1-2.5 h Coal 1200-1400 12-18% 6500-7000 25-40% 3-5 h Brown coal 700-1000 14-22% 3100-3600 15-27% 2.5-4h Pellets / briquettes 700 / 850-1000 6-10% 4300-4700 1-2% 2-3 / 4.5-7 h It should be noted that the characteristics of pellets and briquettes are the most “stable” among all types of fuel. However, there is some difference in performance from manufacturer to manufacturer. For example, RUF fuel briquettes have one of the highest calorific values - up to 5200 kcal / kg, while their moisture content can reach 12%. The shape of the briquettes may also differ. Unlike rectangular RUF bricks, Pini-Kay briquettes are hexagonal with an axial hole. Because of this, it is not so convenient to store them, but they burn out faster and more evenly..

Fuel storage rules

The energy efficiency of any fuel depends on how appropriate the storage conditions were. Coal and peat are immersed in storage only after a week of drying in clear weather with 2-3 times stirring. Firewood is stored in carefully folded piles with obligatory treatment with antiseptic and insecticides. As you can see, in most cases, only the storage rules are important; over time, the fuel does not lose its qualities.

This cannot be said about briquettes and pellets, which, due to their low humidity, tend to draw water from the air. The storage place for briquettes should be arranged inside a closed room. Usually briquettes are stacked in compact stacks on pallets to maintain air circulation from below. And although most of the products have a sealed plastic packaging, there is always a risk of damage and contact with the external environment, which leads to fuel swelling and deterioration. Therefore, they try to maintain a dry atmosphere in the room and avoid sudden temperature changes..

Use of briquettes and pellets

Most often, briquetted fuel is used in solid fuel boilers; Euro wood is especially effective in pyrolysis units. Briquettes for a rough oven are not suitable due to an insufficiently high combustion temperature, but they can be successfully used for a Russian oven. The use of pellets is possible only if there are appropriate grates in the firebox..

Artificial fuel is ideal for sauna or sauna stoves, not least due to the complete absence of waste. In fireplaces, briquettes are more effective than wood, although for aesthetic reasons, many people prefer wood. But in the preparation of barbecue there is no difference, except that it will take a little longer to wait until it burns out..

What are some important factors to consider when selecting and applying solid fuels for boilers?