Recommendation points

In this article: how the panel house fencing works; what is glued laminated timber and thermobeam; analysis of erroneous opinions about panel houses and houses from a bar.

What should be a reliable and beautiful home, what are the costs really worth incurring to create it? These two questions haunt every potential homeowner like the sword of Damocles, because newly built housing must successfully withstand the very harsh conditions of the Russian climate. Yes, somewhere out there, in the great and immense foreign countries, panel houses and built of timber regularly serve their owners, withstanding the cold and the onslaught of various hurricanes with human names, but in Russia these very panel buildings and buildings built of timber do not have the slightest chance … or is?

Panel houses – anatomy of cladding

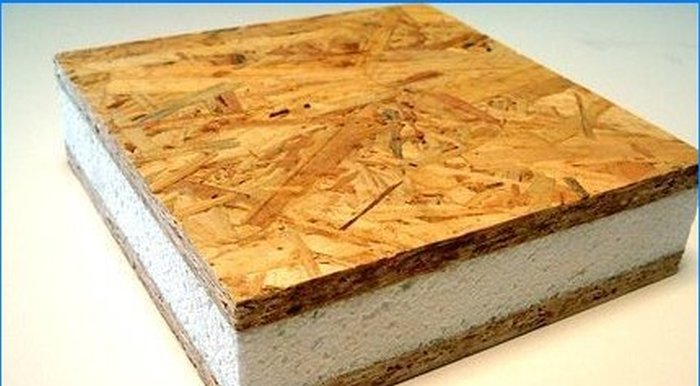

The main operational advantage of frame-panel houses lies in SIP-panels – a kind of sandwich, consisting on the outside of 12 mm OSB-plates and a filling of a 100-150 mm layer of insulation, more often expanded polystyrene, less often a basalt mat.

OSB board consists of three to four layers of wood (pine or aspen) shavings, usually glued together with melamine-formaldehyde, urea-formaldehyde and urea-formaldehyde resins, which contain boric acid and synthetic wax. A number of modern manufacturers of oriented strand boards use polyisocyanate glue (MDI) for gluing layers of chips, which does not contain phenolic and formaldehyde resins. The orientation of the chips in the OSB board is different and depends on the layer in which it is located: in the inner layers, the chips are oriented along the width of the board; in the outer layers – along its length. In the sandwich of SIP panels, an OSB board of at least the third class is used, intended for the construction of load-bearing structures operating in especially humid conditions.

It should be noted that in a number of its characteristics OSB board surpasses many types of boards made from shavings:

- high mechanical strength, exceeding, for example, the strength properties of chipboard by 2.5 times. In terms of their strength, OSB boards are only slightly inferior to plywood;

- the holding properties of nails and screws are almost equal to natural wood;

- stable form. Complete absence of structural defects typical for other wood chip boards, such as voids and cracks, warped areas and places with fallen out knots;

- the internal structure of OSB boards is uniform throughout the volume, the quality of both external surfaces is identical;

- high moisture resistance;

- easy machining. The boards can be cut, grinded and drilled using ordinary carpentry tools, glued and painted with any paints and varnishes intended for wood;

- OSB boards are not affected by insects;

- surface treatment with special means increases resistance to moisture and open flame, as a result, the characteristics of moisture and fire resistance of OSB boards are higher than those of solid wood.

The characteristics of the filling of SIP panels used in the creation of panel houses are given in the articles on expanded polystyrene and mineral wool. Ready-made SIP panels usually have a thickness of 174 and 224 mm, their dimensions are 2,500×1 250 mm and 2,800×1 250 mm, the average weight is m2 – 17 kg. The walls of a panel house, formed by panels of oriented strand board and a layer of insulation between them, withstand temperature differences from -50 ° to + 50 ° С.

Glued laminated timber – device

This structural material, from which log houses have been created over the past 100 years, is made from pine, spruce, larch, cedar and fir wood, the debarked trunks of which are cut into lamellas, from which bags are formed and glued together with melamine, resorcinol or polyisocyanate glue. (MDI) – a layer of glue is applied in the thinnest layer. Before gluing, the lamellas are graded and dried. Then they are rejected again, examining for cracks, knots and chips (wane) along the lines of the edges and slopes. Wood stress in their structure is relieved by sawing and pressing during the formation of packets, which completely eliminates the formation of through cracks and prevents any distortions. Fibers of adjacent lamellas in the package are selected with the opposite orientation of the fibers, which increases the strength of the final product.

In addition, the strength of some load-bearing elements of the house structure (rafters, floors, columns, trusses, etc.) is additionally enhanced – metal or plastic reinforcement is glued into the middle of the lamella packages. The ends of the lamellas of various lengths are profiled (milled) to obtain toothed grooves, with which they are spliced using glue and pressing to the required length – the production of laminated veneer lumber allows the production of structural material of unlimited length. In addition, with the help of a router, connecting nodes (as a rule, “groove-comb”) of building structure elements are formed – houses from a bar are assembled at the installation site like a Lego-constructor, all elements of one building are prepared only at the factory. At the final stage of production, the finished glued timber is treated with antiseptic and fire-retardant special means. Glued laminated timber is produced with a thickness of 200 to 400 mm, most often 200 mm, because more thickening seriously affects the increase in its cost.

The timber glued from lamellas has the following characteristics:

- shape stability, i.e. there will be no deformation changes during the operation of a house made of laminated veneer lumber;

- almost complete absence of shrinkage (no more than 2%), including seasonal;

- precise geometry of shapes;

- resistance to moisture and seasonal temperature changes;

- the strength of laminated veneer lumber is 70% higher than that of wood;

- compared to wood, the thermal conductivity of laminated veneer lumber is lower due to the absence of cracks and other structural damage;

- significantly lower, in comparison with any other glued wood materials, the content of glue;

- fire resistance.

In addition to the described glue bar, there is another interesting type of it – a thermal bar, consisting of two outer lamellas with a thickness of 40 to 80 mm and an inner layer of extruded polystyrene foam with a density of 45 kg / m3. The expanded polystyrene insert, rigidly fixed inside the structure of the bar with the help of wooden ribs and an adhesive layer, reduces the thermal conductivity by 2.5 times, i.e. at 200 mm thickness, the thermal beam retains heat better than glued laminated timber of 400 mm thickness.

With higher heat resistance values, laminated veneer lumber with insulation inside has a lower price and weight than glued laminated veneer lumber. In the process of assembling a house from a thermo-beam, a glued beam is laid in its lower tier and in the sections of wall dressing, which does not contain insulation in its structure – thereby additional rigidity of the structure is achieved. Unlike houses made of thermo-beams with 200 mm thick enclosing walls, walls made of laminated veneer lumber of the same thickness, in accordance with the requirements of the RF Law “On Energy Saving” No. 261-FZ, will have to be insulated – in the cold season they will not be enough and either insulation or a wall with a thickness of at least 400 mm is required.

Popular misconceptions

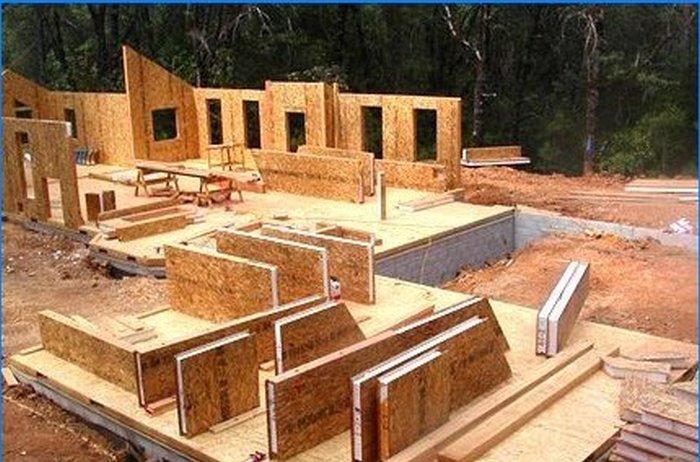

In Russia, and in the rest of the world, any new technologies first run into the wall of public opinion, mostly conservative. If log baths can be completely assembled and prepared for operation in just a month or two, this is considered bad, because “real” baths must go through several stages of shrinkage and repeated caulking of cracks. And the panel house? Its construction was immediately labeled “short-lived”, because there are no such usual external walls made of concrete, brick or even wood. Consider a few common opinions of this kind …

“Panel houses and houses built from a bar, and even more so from a thermobeam, are short-lived”.

This statement is true in one case – if the house is not properly cared for. And without maintenance and periodic repairs, any, even a stone house, will certainly decay and collapse. The advantages of a panel house are that any damaged fragment of the enclosing structures can be easily replaced without the inevitable damage to the adjacent sections, as it would be when performing a similar operation with a brick wall. Houses from a bar also need periodic maintenance – surface treatment with special means. Proper care will ensure that your home lasts for at least 50 years.

“The fire hazard of panel boards and houses from a bar is much higher than that of brick houses”.

And this statement is also true – many houses built using these technologies and from these materials burned down immediately after their commissioning. However, the reason for this lies not at all in the construction materials, but in the “curvature of the hands” of the builders who installed chimneys, ventilation systems and electrics. The problem is that many performers who publicly declare their competence in building houses from timber and panel houses, in fact, represent the assembly process very poorly and in general terms – the technology is still new for Russia, professional installers are not enough. As for the fire hazard of structural enclosing materials, they all undergo compulsory processing with several layers of fire retardants, which prevent direct flame contact with them..

“Low heat capacity of walls – panel houses need to be heated more”.

Indeed, the heat capacity of walls in panel houses is practically absent, but why is this considered a disadvantage? Judge for yourself: during the cold season you come to a brick house that has been without heating for some period and you need to heat it up in order to ensure the required temperature in its rooms. It is not possible to heat such a house for 18-20 hours – heat-intensive walls will absorb heat, therefore, all the heat energy produced during this time is only for heating the walls. And in the switchboard house only its premises are heated – no energy consumption for heating the walls.

“Panel houses and timber houses are equally not environmentally friendly, because phenol-formaldehyde resins are used to create their elements”.

The resins mentioned are indeed present both in the insulation and in the structural elements of these houses, but their content is much lower than in a conventional chipboard wardrobe located in your bedroom. However, today many manufacturers of OSB boards and laminated veneer lumber are abandoning phenol-formaldehyde adhesives in favor of a polyisocyanate adhesive that does not contain either phenol or formaldehyde. By the way, in our time, when choosing any building materials, it is worth asking if they have a certificate of environmental safety.

“Shield houses will not withstand earthquakes and cannot withstand strong winds, because weigh too little “.

In this statement, it is only true that such houses really weigh little, so they are easy to transport and do not require the use of heavy construction equipment during construction work. As for the resistance to earthquakes and strong winds, it is better to give the following examples from real life:

- 1995, Kobe (Japan). The 7.3 magnitude earthquake destroyed bridges and marinas, more than 200 public and residential buildings. Meanwhile, six buildings built using SIP technologies, located just 16 km from the epicenter of the earthquake, not only did not collapse, but did not even receive noticeable damage;

- 1992, Florida (USA). Hurricane Andrew, with wind speeds of 285 km / h, caused colossal damage to housing in Franklin, raging in it for more than 5 hours. The panel houses that were in this city withstood the onslaught of the hurricane, receiving only minor damage to the roof.

It should be noted that hurricanes with such wind speed have never been observed in Russia..

“Panel houses and houses made of timber are too expensive”.

Everything is so – the price of construction materials for these houses is not at all cheap, and specialists are required for the construction itself. However, let’s look at it from the other side: the construction itself will take no more than 60 days, and half of this period will be spent on foundation work and external communications; there will be no additional work on the facade and, by and large, interior decoration; all structural elements are fitted to each other at the factory, i.e. they only need to be collected on site. And if you can use a brick or wooden house no earlier than in a year, then a panel house and a house made of timber will be at your disposal in less than 2 months.

Modern houses are much more technologically advanced than the old buildings we are used to, which makes it possible to facilitate the construction process itself and significantly reduce the heat loss of the house during the cold season. And a turnkey bath professionally made of timber will become not only an ideal place for water procedures, but also a real decoration of a summer cottage, because its design has no flaws, both external and internal. In conclusion, I will note an important aspect of any construction – construction work should be entrusted to real masters in their business, and then the house will come out great.

What are some common misconceptions about panel and laminated veneer houses? Can you clarify any concerns or doubts readers might have regarding these types of houses?