Recommendation points

- Excavation

- Foundation construction

- Waterproofing

- Brickwork

- Concrete works

- Installation of wooden structures

- Roofing

- Finishing work

You can build a house in winter, observing all the necessary requirements for the production of work in these conditions. Additional costs and efforts are justified when it is necessary to reduce construction time. The quality of the finished house will not suffer if the technology of work of each stage is strictly followed.

Excavation

If before the onset of cold weather it is known where the foundation will be located and its dimensions, then it is better to carry out preparatory work to insulate this place. Such activities will significantly reduce the cost and effort of earthworks..

The soil is protected from freezing:

- preliminary loosening and harrowing;

- salinization;

- covering the soil surface with heat-insulating materials;

- retention and increase of snow cover.

The soil is loosened to a depth of 0.35 m, and harrowed by 0.15 m. The soil is covered with sawdust, dry peat, slag, pine needles, dry leaves or artificial thermal insulation materials. It is necessary to fill the soil before the onset of cold weather:

- in 5-15 days – sandy soil;

- in 20-25 days – clay soil.

Salt consumption per m3 soil is 10-16 kg in accordance with the average soil moisture (fraction of a unit) 0.08-0.16 in the freezing area. The method of defrosting using direct heating is expensive and is used only in the case of a small amount of work and if it is impossible to apply another.

At temperatures below -10 ° C in freezing soils, the walls of pits and trenches need not be strengthened if freezing during excavation occurs by 10 cm as it deepens. In dry sands and during the passage of aquifers (water-saturated, limited by impermeable soil layers), wall fastening is necessary.

The pit or trench is not deepened to the level of the foundation to prevent freezing of the base. To the end, the soil is removed directly in front of the foundation. After its installation, the base must also be protected from freezing. For this, the sinuses are backfilled with thawed soil. From the side of the basement, backfilling with slag or other insulating materials is arranged.

Important! In water-saturated soils, the foundation for the foundation is not recommended in winter.

Foundation construction

Erection of foundations on a frozen base is possible only in the case of non-porous soils (soils that do not change in volume when frozen).

A feature of the construction of foundations in conditions of negative temperatures is the creation of normal conditions for the process of setting mortar or concrete.

The construction of the foundation made of ready-made reinforced concrete piles in winter is no different from the summer period. Especially if the soil is not frozen enough and the foundation is formed from driven or screw piles. All work with monolithic concrete placed in winter requires special measures.

Foundations that are erected using mortar (strip from ready-made concrete and reinforced concrete blocks, brick, rubble masonry, etc.) are made by freezing, using antifreeze additives, as well as using solutions without additives and further strengthening the structure by heating. All activities are the same as in brickwork and are described in detail in the “Brickwork” section.

Important! It is impossible to lay the foundation in winter on a sand cushion more than 10 cm thick.

Concreting at subzero temperatures is carried out either by the open “thermos” method, or by closed – in hothouses or tents. This is discussed in more detail in the section “Concrete works”.

Waterproofing

All surfaces that are covered with a coating or asphalt waterproofing in winter conditions must be warmed up to a positive temperature. The workplace is protected from wind and precipitation.

Rolled insulating materials are delivered to the place of work heated to a positive temperature and, if necessary, in a warm container. In this case, they should be warmed up to at least +10 ° С, cold mastics – +30 … + 35 ° С, impregnation – +25 … + 80 ° С. The degree of heating depends on the selected insulation.

In the open form, the gluing waterproofing device is possible at an air temperature above +5 ° C, at a lower temperature, it is necessary to install greenhouses. Coating, asphalt waterproofing is performed at temperatures up to -20 ° С.

The temperature of bitumen-emulsion mastics without additives is +70 ° С (at an air temperature of -10 ° С). It is better to dry the fresh coating with heat guns. All formulations with antifreeze additives are applied in layers 2 mm thick with a break in work from 3 to 5 days.

In greenhouses at temperatures from +5 to +10 ° C, waterproofing is performed by painting with furan and epoxy mastics.

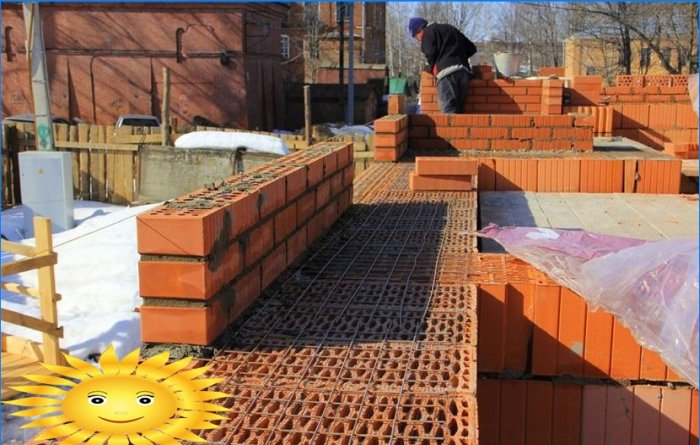

Brickwork

The brand of mortar for winter masonry increases by one order of magnitude. If antifreeze additives are not used, then the dressing should be done in a single row. When stopping in work, mortar must not be laid on the surface of the last row, which in turn must be covered to protect against icing and snow.

Laying in winter is done in several ways:

- using antifreeze additives in solution;

- with warming up the masonry to strengthen the structure;

- freezing.

Solutions with antifreeze additives and a grade of at least 50 set at low temperatures without heating. When installing reinforced masonry, additives are selected taking into account the effect on the metal in order to exclude corrosion.

The masonry is heated using electrodes placed in horizontal seams. A current is passed through them, which heats the structure, while reducing the setting time and preventing the freezing process.

The principle of the freezing method is based on the fact that after thawing, the solution hardening process resumes. Here it is important to use the heated solution within 30 minutes, so it is prepared in small portions..

Masonry by freezing without additives in the mortar can be used for buildings less than 4 floors and below 15 m. In this case, the mortar is used with a temperature from +10 to +20 ° C in accordance with an air temperature from 0 to -20 ° C. Heated sand and water can be used to make a solution of the required temperature..

Important! Do not heat the prepared solution with hot water.

At the floor level, it is necessary to lay ties in the corners, at the joints of the walls. If in a brick building, erected by the freezing method, internal heating is provided, metal ties are laid at the level of the bottom of the windows.

Ties are made of reinforcement with a diameter of 12 mm and are wound in each direction by 1.2–1.4 m. At the end of the tie, a loop is made into which an anchor with a diameter of 12 mm, 300 mm long is inserted, which is welded to the loop.

During the defrosting period, observe the draft and verticality of the walls. To prevent overvoltage in some areas of the masonry (piers, pillars, etc.), unloading reinforcements are installed.

Concrete works

Before starting the preparation of the concrete mixture in winter conditions, it is necessary to carry out preparatory work:

- protect stocks of all concrete components from freezing;

- prepare heating devices (steam comb, electric furnace, transformer, electrodes or analogs);

- heat up containers for transporting concrete mix;

- mechanisms used for the manufacture and placement of concrete are lubricated with winter oils.

In accordance with the purpose of the building structure, various methods are used to create the necessary conditions for concrete hardening:

- Thermos way. This method involves heating the constituents in the manufacture of concrete. The hardening process takes place with the release of heat, which maintains the required hardening temperature. Before concrete gains full strength, it must be insulated.

- The second method involves heating the components of the concrete mixture (sand, coarse aggregate, water) and, to reduce the time of concrete hardening, heating the structure (with steam, warm air, electricity, in a heating formwork, infrared and induction heating).

- The use of anti-freeze additives (sodium nitrite, calcium nitrite with urea, etc.) provides a liquid state of hardening concrete, which makes it possible to gain strength at low temperatures. The choice of additives must be carried out in accordance with building codes.

- Concrete work is carried out in movable or portable greenhouses with heated concrete mix.

For foundations, walls, partitions, columns, beams, floors, the thermos method is used with accelerated hardening by heating the structure. Concrete preparation, floors are arranged using the thermos method with steam heating and using flat greenhouses.

If the concrete mix is laid in layers, then the old layer is warmed up to a depth of 300 mm before the new one is laid. It must also be insulated until it is filled with a new layer of at least 50% of its full strength..

The reinforcement is also heated to a positive temperature before pouring it with a concrete mixture. In all cases, after the end of concreting, it is required to cover the concrete surface with heat insulators. The necessary conditions for concrete hardening are preserved until its strength reaches at least 70%.

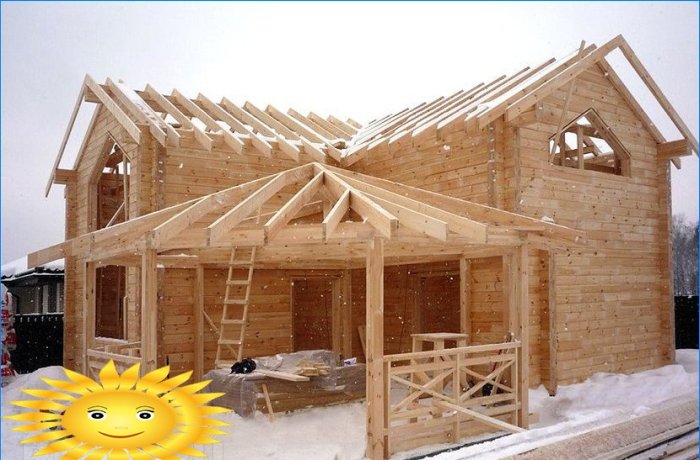

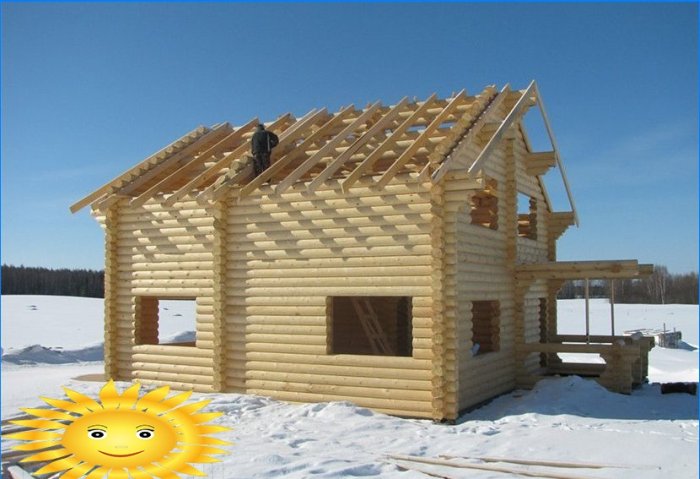

Installation of wooden structures

Preparation of elements of wooden structures (impregnation, painting, sawing, cutting, etc.) must be carried out in a warm room. In the open air with negative temperatures, only the entire structure is assembled from finished parts. Before assembly, the already processed elements should lie outside for at least 6 hours to equalize their temperature.

Roofing

The device of roofs made of roll materials is allowed only at an air temperature of up to -20 and C. The roof in winter conditions is made in one layer of double-sided roll material with mineral dressing. The rest of the layers reach with the onset of heat.

Important! The base under the roof must be cleaned of ice, snow, frost and heated above 0 ° С.

Roll material, primers, mastics are warmed up to a positive temperature before laying. All preparation for the installation of roofing iron is carried out in a warm room. In tiled roofs, the joints cannot be coated with mortar at temperatures below zero..

Finishing work

All interior finishing works are carried out in rooms with a positive temperature. External plastering works are performed with solutions that harden under negative temperatures..

Indoor painting is carried out under the condition that the coldest surfaces (outer walls) at a height of 50 cm from the floor have a temperature of at least +8 ° C. These rooms must be heated or insulated. In this case, paint compositions should have a temperature above +10 ° С, emulsion – above +15 ° С.

Outdoor painting can be carried out only if the temperature is above +5 ° C during the day. Moreover, the surface to be painted should not come into contact with warm air from the vents and ventilation pipes.

Is it possible to build a house in winter without compromising its structural integrity? Are there any specific techniques or precautions that need to be followed to ensure a successful construction process during the colder months?

I’m curious if building a house in winter affects the construction process and overall quality. Are there any specific guidelines or precautions one should follow to ensure correct construction during this season?