Recommendation points

- Strengths and weaknesses of aerated concrete

- Varieties and varieties

- House foundation

- Bearing capacity of aerated concrete walls

- Heat and sound insulation properties

- Foam concrete wall masonry

Easy-to-process, warm and inexpensive aerated concrete is increasingly used both for construction and for the installation of internal partitions. In this article we will tell you about the grades of aerated and foam concrete, the differences between them, the scope and the main technical characteristics..

Strengths and weaknesses of aerated concrete

Aerated or lightweight concrete (aerated concrete, foam concrete) is a dense homogeneous material, the density of which is very low due to the large number of small (1-3 mm) pores formed during foaming and molding of blanks.

Initially, aerated concrete blocks are formed very large, but they can be cut at the discretion and size of the customer. Ready-made products for masonry are no less common – similar to a cinder block, but only 10 times lighter and sometimes with tongue-and-groove locks.

Lightweight concrete takes a uniform static load well and has a high compressive strength. But with point dynamic effects, it easily crumbles, so critical elements and hinged structures cannot be attached to it.

The advantages of the honeycomb structure include low thermal conductivity and excellent noise absorption of both structural and airborne nature. You have to pay for this with a fairly high water absorption. It would be a mistake to believe that lightweight concrete does not require protection and insulation. In a wall uniform in thickness, condensation forms in the thickness and destroys the structure, therefore, aerated concrete walls are not a panacea at all. They are also demanding on adherence to installation techniques and need protection like any other building material..

Varieties and varieties

Aerated concrete and aerated concrete are often considered as completely different building materials. This is partly true, because different pore-forming substances are used in the manufacture. Foam concrete is positioned as a lower quality material due to the use of chemical foaming agents. In fact, the so-called “local” or monolithic foam concrete, which is prepared at a construction site, has deteriorated characteristics, but it is not considered within the framework of this article.

Factory-made foam concrete and aerated concrete (despite the different technology) can be combined into one class simply because of similar characteristics, in terms of quality, good foam concrete is rarely inferior to its main competitor.

Foam concrete and aerated concrete can be autoclaved and natural drying. The first type is preferable due to the smaller deviation of technical parameters, although in one-story buildings non-autoclaved concretes are used very often and without any special claims..

All other indicators: density, frost resistance and others like them are set by the construction project or typical examples of construction.

House foundation

Many people are attracted by aerated concrete because of the opportunity to save on the foundation as one of the most expensive elements. Aerated concrete is really lighter (often by an order of magnitude) cinder block or shell rock, but to give the required strength, the pillar of the wall must be wide enough: 35–40 cm for single-storey buildings and 45–60 cm for multi-storey buildings. The ratio of width to depth, even for shallow foundations, is at least 1: 2–1: 2.5, so that the structure takes up the edge load, otherwise the foundation deforms during swelling even under its own weight.

Alternative options include strengthening the foundation with screw piles or casting a crown-expander at the top of the basement. In any case, the foundation should not be made thinner than the wall by more than 30–50 mm, despite the fact that aerated concrete manufacturers allow overhangs by a third of the wall thickness. Also, the aerated concrete wall must be isolated from the foundation with roofing felt or other roll waterproofing.

Bearing capacity of aerated concrete walls

The ability of lightweight concrete to take compressive load can be confidently called sufficient, but not excessive. In practice, this is expressed in the fact that the floor beams cannot point-to-point on the wall itself; an armored belt is required to be filled. It should be reinforced, but not necessarily massive. Enough 15–20 cm for roofing or attic and 25–30 cm for interfloor overlap. Beams, if used, can be poured and protected with concrete, although due to the excessive width of the wall, they are often simply surrounded by blocks.

Overlappings from monolithic and type-setting slabs do not need to be poured into the preparatory belt. Sometimes, when pouring the interfloor overlap, a side of thin (8-12 cm) blocks is laid on the outside of the walls and used as formwork. This solution allows you to firmly support the ceiling on the walls and eliminate a very large cold bridge.

Heat and sound insulation properties

Although foam and aerated concrete have high rates of thermal and sound insulation, it is still necessary to make the structure of the wall uneven in order to somewhat optimize these properties. For example, enclosing walls are often laid out in two rows, leaving an air gap, due to which the wall will dry naturally.

Walls made of aerated concrete from the inside almost do not insulate. To stop excess heat transfer, one layer of roll insulation up to 10 mm thick is sufficient. In houses made of aerated concrete, the main thermal insulation is taken out in order to bring the dew point into a layer of non-hygroscopic material and protect the wall from blowing. For this, 30-50 mm polyurethane plates with locks on the edges are used..

Foam concrete wall masonry

As for the masonry technique, even amateurs will easily master it. Thanks to the low weight and large size of the blocks, they can be stacked alone and quickly enough.

The first row is laid out on cement mortar of grade 300 over the roll of waterproofing on the foundation. First, the blocks are installed at the corners, they are adjusted in a common horizontal plane with a water level and aligned exactly according to the design dimensions using a laser axis builder. After a few hours, the lacing is pulled over the corner stones and the first row is filled. It is carefully leveled with a rack level and left to dry for a day..

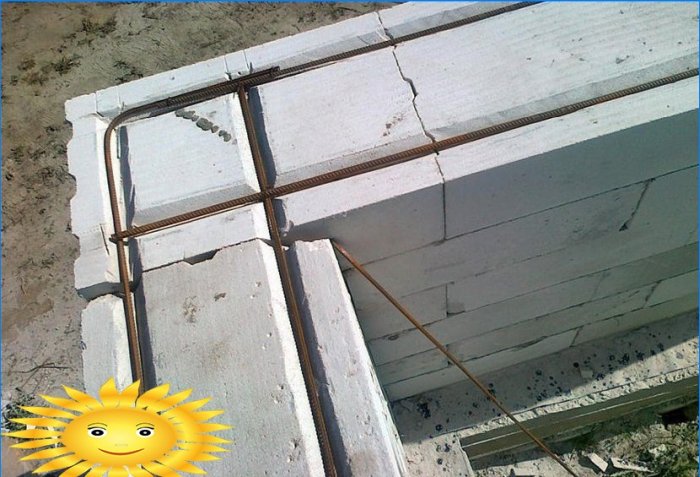

All subsequent rows are laid with an offset of the vertical joints by a third of the block length or at least 150 mm. Blocks can be laid with reinforcement of every second or third row. When all the walls are driven to the common level, grooves are cut at the end using a special scraper, one for every 200 mm of the wall thickness. The profile reinforcement is bent in the shape of the grooves, then the grooves are filled with cement mortar of grade 300 of a liquid consistency and the reinforcing bars are embedded in it. It is optimal if the rods do not break at the corners of the building, but bend with a small radius.

When building from lightweight blocks, it is very important to lay the masonry sequentially and start a new row only if the previous one is completely finished. Before applying the adhesive, the masonry surface must be thoroughly cleaned with a trowel and swept out of dust, especially if the previous row is reinforced.

Vertical joints, contrary to the recommendations of the manufacturers, should also be filled with a small amount of glue, even if there are lock joints

Can you provide more information on the construction features of a DIY aerated concrete house? How difficult is it to build? Are there any specific techniques or tools required for this type of construction?

This article is quite interesting, but I’m curious about the construction process of a DIY aerated concrete house. Are there any specific tools or materials required? How long does it typically take to build such a house, and what are the key steps involved? Additionally, what are the advantages and disadvantages of using aerated concrete compared to traditional building materials? Any insights on the cost-effectiveness and durability of aerated concrete houses would be greatly appreciated.

What are the main advantages of building a DIY aerated concrete house compared to traditional construction methods, and are there any specific construction features or techniques to keep in mind while undertaking such a project?

What are some common construction features of a DIY aerated concrete house? Can you explain the process and materials used in building such a house?