Recommendation points

- The operating principle of the oil furnace

- Description of construction

- Why boost is needed

- Oil oven with heat exchanger

- Chimney rules

- Furnace ignition and operation

When you need an affordable and economical way of heating, many people think about making a stove-stove that runs on waste oil. In this article you will find a description of the typical design, as well as ways to increase the efficiency of the device and make the oven more autonomous..

The operating principle of the oil furnace

Initially, incineration of used oil was only one of the available means of disposal. Craftsmen could not pass by such an energy-intensive fuel and created stoves in which oil burns with minimal formation of soot and soot.

1 – waste oil; 2 – lower container for oil; 3 – damper for air supply regulation; 4 – a pipe with holes for air; 5 – combustion chamber; 6 – top container; 7 – partition; 8 – chimney

Any oil or fuel oil can be used as fuel, as well as some pasty lubricants. Volatile liquids such as kerosene, gasoline or solvents cannot be used in the oven, but small amounts of them can be used for ignition.

Description of construction

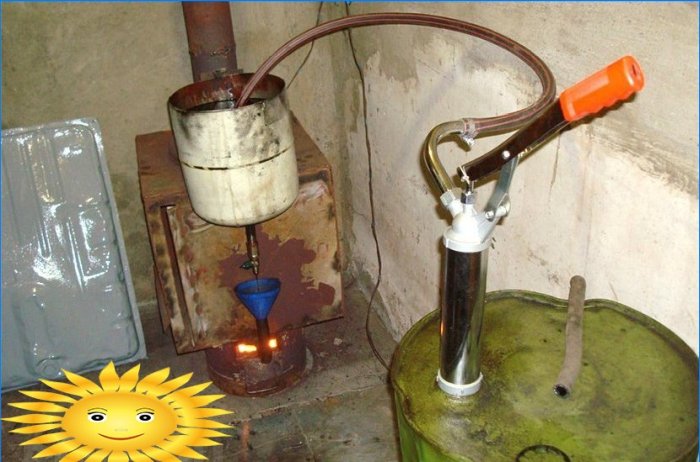

Structurally, the oil furnace consists of two combustion chambers connected by a fairly wide perforated pipe. Since most stoves are made from scrap materials and scrap metal, it makes no sense to adhere to strict dimensions, the proportions of individual structural elements are much more important.

The lower chamber of the furnace is a tank of arbitrary shape, which, when filled to 2/3, can hold 5–7 liters of fuel. Furnace power and fuel combustion rate are directly proportional to the area of the lower chamber. The frequency of adding oil to the furnace depends on its capacity, therefore, the lower chamber is often made very voluminous, up to 20-30 liters. This downward displacement of the center of gravity also ensures the stability of the structure..

3 or 4 legs with bolts at the ends are welded to the bottom of the chamber so that it is possible to adjust the installation level. Also, the oil supply pipe cuts into the bottom, which bends into a siphon for a water seal. It makes sense to lead the end of the tube into an adjacent container of approximately the same size, which serves as a fuel tank. The bottom of the tank should be 2–3 cm below the bottom of the stove to allow the oil to drain completely.

In the upper wall of the lower chamber, a hole with a movable flap must be cut to adjust the incoming air and, accordingly, the oil heating temperature. Also, a pipe with a diameter of at least 100 mm and a length of 35–70 cm is cut into the upper wall. Holes with a diameter of 12–16 mm are made on its surface in 6 or 8 rows at a distance of 7–10 cm from each other.

The upper oven chamber usually duplicates the size and shape of the lower one, but it can be much larger. The higher the internal volume, the more complete combustion can be achieved, but in a chamber that is too spacious, the temperature will be insufficient.

It should be remembered that the manufacture of the furnace and its further refinement are of a purely experimental nature, the same product, depending on the placement conditions, can work with different efficiency. Over time, from a simple stove for heating a garage or workshop, such a stove can turn into a full-fledged heating unit for the whole house, capable of operating in automatic mode. To do this, the furnace is equipped with a drop oil supply, a water heat exchanger or forced pressurization..

Why boost is needed

To increase the efficiency of the furnace, two types of air fans are used: pressurization and external blowing. The latter option is appropriate if a room that is impressive in terms of area is heated by a stove and it is not necessary to count on natural air convection. In this case, a conventional fan helps the case to give off heat more efficiently, the air flow is directed to the place of greatest heat.

Internal blowing is designed to enrich the upper chamber with oxygen, which contributes to a deeper disintegration of fuel particles, as well as its longer combustion. With the use of forced airflow, the so-called “blue flame” appears, indicating a smokeless combustion process.

Air discharge is carried out by a conventional duct fan with a capacity of 250 m3 in hour. Usually it is placed on the floor next to the oven and connected to the upper chamber with a rigid air duct with a diameter of 100 or 110 mm. To connect the air duct, a piece of pipe of the required diameter is cut into the upper chamber, into which a damper is inserted to regulate the air flow. To avoid counter-draft, it is recommended to install a sensitive non-return valve immediately after the fan..

Oil oven with heat exchanger

Often, an oil stove is used as a boiler for water heating. This is possible after installing a heat exchanger in the upper combustion chamber. For good heat transfer, you will need a container of impressive dimensions – about 30-50 liters. A heat exchanger is mounted inside the chamber, it can be a coil or a system of pipes made of steel, or an internal tank.

Due to the fact that the passage of combustion products near the heat exchanger is difficult, soot and soot form much faster, condensation may also appear during the ignition process. To facilitate cleaning, the heat exchanger must have at least one flange connection sealed with an asbestos cord.

The role of the coolant in the system is usually assigned to antifreeze or special fluids. The heat carrier must constantly move, therefore a circulation pump is built into the heating circuit.

Chimney rules

For an oil stove, it is very important to have a stable and powerful draft, so the chimney height should be at least 4 meters. Usually a steel pipe with a diameter of 100 mm or more is used for the chimney device.

No more than two turns of the chimney are allowed, but only with the correct arrangement of connections at the corners and only from vertical to horizontal. The turns must be made through tees installed on vertical segments. One of the branches of the tee must point straight down and have a removable metal plug to collect the resulting condensation.

The final vertical segment of the chimney can be made of an asbestos-cement pipe, but a brick protective well will be required to a height of 2-2.5 meters.

Furnace ignition and operation

For lighting, you can use paper or rags, or easily flammable liquids. In the first case, oil should be added in small portions to the combustion center. In the second, add a small amount (50–70 grams) of solvent or gasoline to the first chamber, which is 2/3 filled with oil, and ignite with a lighter with a long torch as soon as possible, without waiting for the formation of explosive vapors.

In operation, the oil furnace is completely fireproof, its design does not allow the formation of an open flame. However, there is a danger of oil ejection from the chamber due to overflow or water ingress..

About once a month, you need to clean the furnace: remove carbon deposits in a container with oil, after knocking the furnace with a hammer. In the upper chamber, especially in the presence of a heat exchanger, soot accumulates faster and is badly chipped off; it must be brushed off with a metal brush. For ease of maintenance and cleaning, it is recommended to make the camera bodies detachable. For example, using double collar covers. The connection of the stove to the chimney and the fan must also be detachable..

Is it possible to build an affordable DIY furnace suitable for exercise purposes? I’m looking for an economical solution that allows me to work out effectively without breaking the bank. Any recommendations or ideas on how to create one? Would love to learn from those who have successfully ventured into this area!

Building an affordable DIY furnace for exercise purposes is indeed possible. One cost-effective option is to construct a simple sauna using readily available materials. You can use a small enclosed space, like a shed or a small room, and insulate it properly. Install heating elements or infrared lamps that emit heat. Utilize a temperature control system, such as a thermostat, to regulate the heat. Additionally, ensure proper ventilation for safety. This DIY approach can provide an effective workout environment without burdening your budget.