Recommendation points

- Furnace foundation

- Iron elements of the furnace structure

- How to combine fireclay and ceramic bricks

Sometimes a recently folded stove, after a season, may require repair: cracks have gone through the masonry or the firebox door has ceased to close tightly and the stove is fuming because of this. Why is this happening? Are these defects in the work of the stove-maker or just ignorance of the tricks of the stove-mastery? Let’s figure it out together.

Furnace foundation

The first thing with which the “longevity” of the furnace begins is a correctly laid foundation. This primarily concerns hearths made of bricks, due to the considerable weight of this material. In addition, the foundation plays the role of a damper cushion, which compensates for seasonal ground fluctuations and reduces the risk of destruction of the furnace masonry..

There are two principles of furnace operation:

- periodic – when the stove is rarely operated (dachas, baths, gazebos). As a rule, the soil in such rooms freezes in winter and experiences seasonal fluctuations (movements);

- permanent – in this case, the stove is in a room with year-round operation. In this case, the soil under the base of the furnace does not freeze, but there is a risk of groundwater approach.

Both in the first and in the second case, there is the main rule for casting the foundation – in order to compensate for the pressure of the furnace on the ground, you need:

- lay the area of a monolithic slab 20% more than the area of the base of the furnace;

- pour 10 cm of reinforced concrete for each ton of furnace (lay a new reinforcing belt every 10 cm);

- raise the upper level of the cast foundation above the ground level by 10-15 cm and make it waterproof with waterproofing, construction mastic or roofing material.

Under the condition of periodic operation, pay attention to the depth of soil freezing, this is true on heaving soils and in those places where groundwater passes close to the earth’s surface. In this case, you need to cast a columnar foundation to the monolithic base slab at least 2/3 of the depth of soil freezing.

It is strictly forbidden when constructing a foundation for a brick-built stove:

- Lay the foundation in the form of brickwork (bricks are laid in the foundation pit and reinforced). Brick is less homogeneous, more hygroscopic and more susceptible to destruction than concrete.

Remember! Brickwork is less durable than reinforced concrete and cannot withstand seasonal ground fluctuations.

- Arrange the base of the furnace from wooden elements (frame, racks, logs, etc.).

Remember! Wooden parts, even treated with a special solution, are susceptible to rotting, and after several seasons the strength of the racks decreases several times, especially for furnaces with a periodic operating cycle..

Iron elements of the furnace structure

Many craftsmen often use metal elements when laying stoves. First of all, this concerns the lintels above the firebox, the arch of the furnace and other places where it is structurally difficult to do without metal lintels.

And it is the iron integrated into the masonry that causes the furnace to break down. The thing is that the coefficient of linear expansion of iron is 65% higher than that of ceramic bricks. Therefore, when heating iron elements (corner, channel, etc.), bricks are squeezed out of the masonry.

To avoid this, it is recommended not to lay a metal corner over the ceiling of the furnace furnace, but to use a wedge-shaped lock.

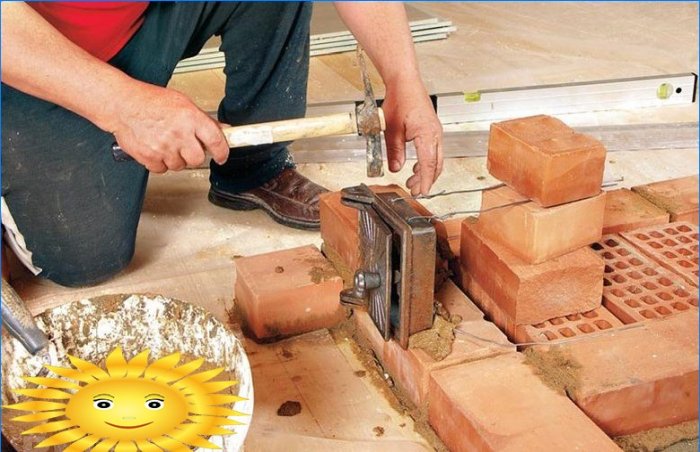

Making a wedge lock:

- An opening is laid out according to the dimensions of the door (always with a margin of 5–7 mm). Basalt cardboard is laid in this space, which will avoid the penetration of smoke into the room and will serve as an ideal heat insulator between iron and brickwork, allowing to compensate for the pressure of expanded iron on the furnace masonry.

- We temporarily install the door, and put a row of bricks on top of it, and the row is not complete, but in the middle we insert a brick, cut into a wedge.

- With the top row we press the checkpoint and leave everything until the solution has completely set..

Another trick when installing the firebox door is the refusal to use long metal “braids” that hide in the masonry, because of which, when replacing the door, you have to disassemble most of the firebox masonry.

The procedure for replacing and installing the furnace door:

- Using a grinder, we cut off the fastening on the door (wire, twisting, metal bands, etc.).

- We take out the door from the opening and cut off the protruding ends of the fastening flush with the masonry.

- At the ends of the perimeter, we make marks opposite the seams.

- At these points, we drill through holes with a 7 mm drill (we make a hole on a cone in order to drown the self-tapping screw in it later).

- We put the door in place and screw the self-tapping screws for ceramics (6×120 mm) into the holes using a screwdriver (the minimum number of screws for a standard firebox is 6 pcs..

Question:Is it possible to do without a metal corner when creating a long span (over the fireplace, over the firebox of a Russian stove, etc.)?

Answer:It is possible, but for this you need to connect several bricks into one pallet using a long rod.

Creating a pallet of several bricks:

- We make two holes in the brick in two passes. First, we drill with an 8 mm drill (the drill should work without a bump stop), then we go through with an 18 mm drill.

- We connect bricks in a pallet.

- We tighten on two bolts using a wide washer.

- We install the pallet in the oven masonry.

It is impossible to do without a metal corner when creating a furnace roof, but so that it does not cause the masonry to diverge, when installing it, you must always leave a gap between the wall and the corner of at least one centimeter per one running meter.

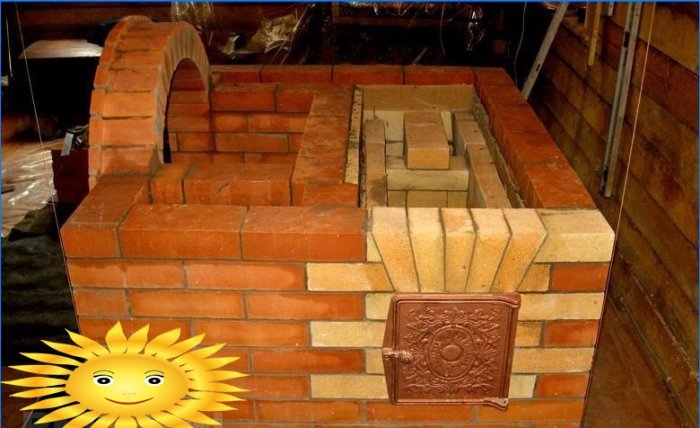

How to combine fireclay and ceramic bricks

There is often a problem when the walls of the furnace, in which the furnace is lined with fireclay (refractory) bricks, begin to crack, and even swell during periods of maximum operation..

The reason may be that fireclay and ceramic bricks have different coefficients of linear expansion when heated and different limiting heating temperatures. As a result, their close contact during the operation of the furnace can lead to the destruction of the masonry..

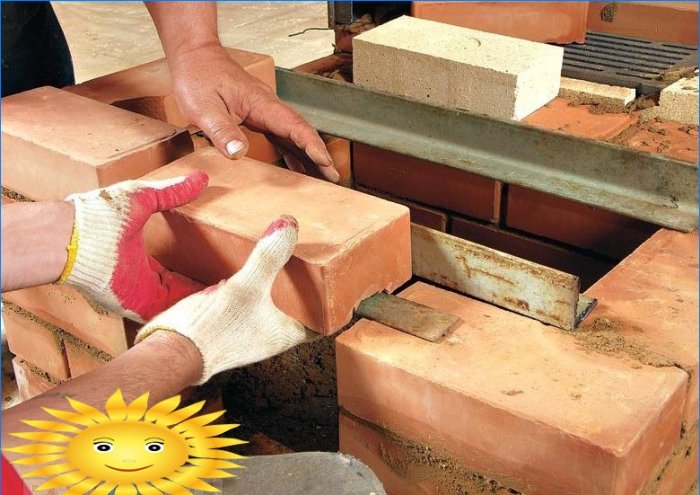

What to do to avoid a “conflict” of bricks:

- We spread the fireclay brick firebox.

- We press the basalt cardboard 5 mm thick against the masonry.

- Leave an air gap of 5 mm between the basalt cardboard and the facing row of the oven masonry (it can be taken out in the upper rows into the convection hole).

This technique will significantly increase the heat transfer of the furnace and the speed of heating the room, as well as the life of the furnace. Now you can not be afraid of overheating bricks during its active operation

There are no trifles in the construction of a brick oven. If you want your stove to serve for many years without repair, then be sure to use the basic rules listed above when laying..

What are some key secrets and recommendations that can help us extend the lifespan of a furnace? Are there any specific maintenance tasks or practices that are particularly effective?