Start. Part 1. How to build your dream house – laminated veneer lumber, material features

House made of glued profiled timberIs the dream of many future homeowners. We talked about the features of the material and technology in the previous article, now it’s worth discussing the intricacies of interior decoration and, again, dispel some myths and give answers

to frequently asked questions.

We order timber

When purchasing a glued profiled beam, you should pay attention to the origin of raw materials. Ideally, it will be coniferous wood (pine, larch, etc.) growing in the northern regions of the country of winter felling. Such a tree itself is more durable and less susceptible to biological damage. The location of the production is also important, it is better when it is located in the cutting area, and not at the other end of the country..

The fact is that a raw board suffers greatly during transportation over long distances, one blue is worth it, no, of course, this will not affect the quality of the timber, since defects are cut out, but the rejection will be much more significant. And as anyone who has even the slightest idea of the economy knows, all costs are included in the prime cost, so you will also pay for the “firewood”.

Interior and decoration

The technology of production of glued profiled timber allows the house to do without additional interior decoration at all.

The essence of the splicing technology completely deprives glued laminated timber of all defects, such as unhealthy knots, rot, blueness, cracks, etc. Thus, the plane of the bar has a perfectly flat, so-called furniture surface, and moisture removed almost completely at the molecular level deprives it of the ability to deform and the appearance of the above defects in the future. But besides this, the customer can prescribe individual technical production conditions, for example, the minimum length of the lamella for splicing, the number of knots per meter or their complete absence, leave only light knots and remove dark ones, etc. This means that “at the exit” you will receive an individual building material and a finished interior to your taste, and not according to the principle, as you are lucky with the array. Someone prefers a natural look of wood with large healthy knots, someone on the contrary wants a “furniture” surface.

For a “natural” finish of such a material, it is enough to use an impregnation for wood, it can be a bioprotective or complex fire-retardant impregnation, preferably based on varnish, you can diversify the color scheme in accordance with the general interior of the room using toning impregnation.

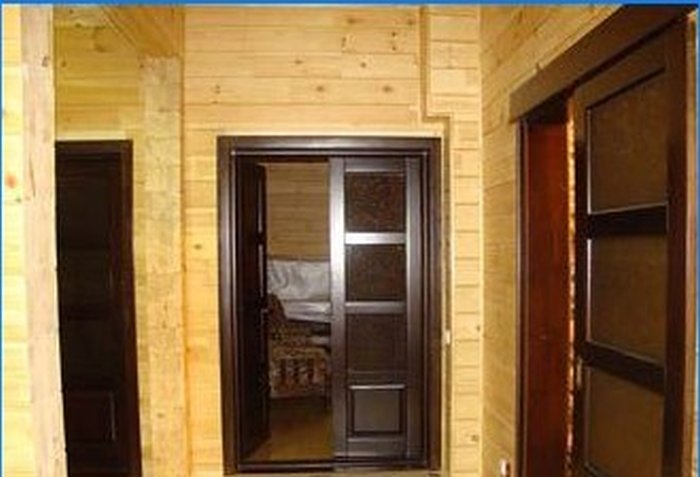

The environmental friendliness and beauty of wood is undeniable, but what about the interior decoration, is it necessary in principle and what to do if you want variety in the interior. The house is still not a one-room apartment, and perhaps in different rooms you would like to see

other finishing materials – no problem, not using other types of finishing is just an opportunity, not an obligation. There are no obstacles for this, as mentioned above, glued laminated timber has a very smooth and even surface, so you do not

additional work will be required to level the walls. If you want walls made of plasterboard for painting or wallpaper – please, the gypsum board can be attached directly to the timber without creating a profile structure. If you want to sheathe with panels (clapboard) of elite wood species, it will not be difficult either. Dense wall coverings such as textured bamboo wallpaper, cork, etc. can also be glued directly onto walls if necessary.

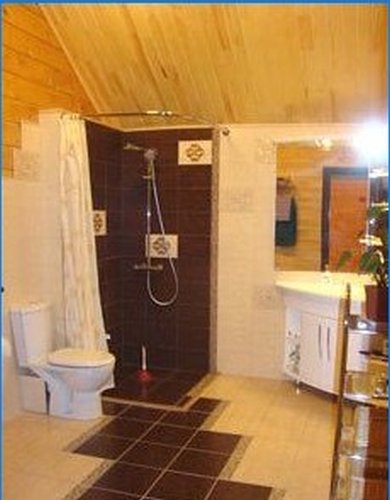

Rooms with high humidity are under a special question – a bathroom, a kitchen – often people are confused by the presence of natural wood in such rooms. Firstly, remember the Russian bath, whether it is built of natural wood and does not suffer from this fact at all, and secondly, preliminary drying of individual lamellas removes moisture from the wood at the molecular level and it will not allow the timber to be saturated through and through in the future. … And thirdly, no one forbids the use of ceramic tiles as decoration. Moreover, there is no need to bear the costs of preliminary wall cladding with sheets of gypsum fiber board, for example, the tile is remarkably glued directly to the tree, modern technologies allow this. The only condition is not to skimp on the quality of the tile glue and take a specialized one for complex surfaces, it is desirable that the tree be indicated in the instructions as possible bases, there are such glue and there are quite a few of them, well, do not forget to prime the surface beforehand.

Thus, the interior and design of your home will depend only on your desires and preferences and cannot be limited by conventions..

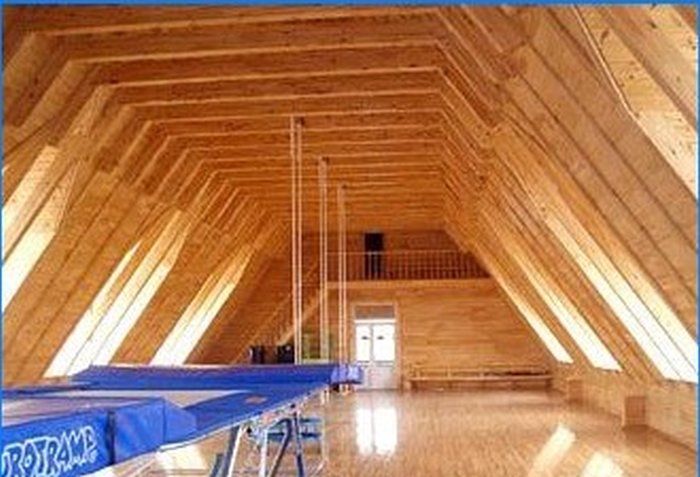

By itself, glued laminated timber is a fairly light material and due to the fact that its length reaches 12 m or more, it allows the execution of structures of even very complex architectural forms.

Start. Part 1. How to build your dream house – laminated veneer lumber, material features

Can you provide more information on the process and benefits of using glued laminated timber to build a dream house? How does it differ from traditional building materials, and what are the factors to consider in choosing this method for construction?

Glued laminated timber, or glulam, is a strong and versatile building material made by bonding individual layers of wood together with adhesives. It offers several benefits for building a dream house, including strength, durability, and design flexibility.

One major advantage of using glulam is its ability to span long distances without the need for intermediate supports, allowing for open floor plans and unique architectural designs. Additionally, glulam is more environmentally friendly compared to traditional building materials like steel or concrete, as it is made from sustainably harvested wood.

When considering glulam for construction, factors to think about include cost, availability of materials, and the expertise needed for installation. It is important to work with a qualified engineer or architect to ensure the structural integrity of the building and compliance with building codes. Overall, using glulam can result in a beautiful, sustainable, and long-lasting dream house.