Recommendation points

- Advantages of a frame bath over other designs

- Internal layout of the bath

- Assembling the frame and walls of the bath

- Installation of thermal insulation and vapor barrier of a bath

- Insulation of the ceiling and floor

- Furnace installation, chimney installation

- Interior decoration (choice of wood)

In this article we will consider an alternative option for building a bath. Using frame technology, you can build your own sauna quickly, economically and with minimal labor costs. Moreover, this bathhouse in its characteristics will not be inferior to structures erected in the traditional way..

Advantages of a frame bath over other designs

In order to build a log or brick bath, it is necessary to perform laborious work and spend significant funds on the purchase and transportation of materials. The construction of a frame bath (in terms of assessing the amount of money spent and time) is more profitable. The use of modern technologies and materials on the market today allows you to build a room for a steam room with the necessary performance characteristics, with less consumption of expensive building materials.

In addition, the frame bath is not prone to shrinkage, which is typical for both log and brick structures. The lightness of the structure allows construction on a columnar or shallow strip foundation, which also makes it possible to save time and materials.

This technology also has disadvantages. First of all, you need to understand that a frame bath is a less durable structure than a brick structure, which means that its service life will be shorter. It is necessary to periodically repair the exterior plaster or cladding material. But the main disadvantage of such a bath is the danger of fire: despite all the precautions, wood still remains a combustible material.

Internal layout of the bath

The size of the internal premises depends on the size of the family. In this case, you should be guided by the fact that the timber goes on sale in a standard length – 3 or 4 m each: the width and length of the structure will have to be chosen as multiples of these values. In addition, if the external cladding is planned from siding, you have to take into account that most often it is sold with 6-meter panels..

So, for a large family, the size of a bath can be 6×6 m, for a small one, 3×3 m is enough.There may be intermediate options, for example – 6×3 m.Considering the first option, we will keep in mind that an area of 4×4.5 m must be allocated for the rest room, for the steam room – 2×2.5 m, for the shower room we will leave 2×2 m, and we will build a dressing room with a size of 6×1.5.

In the second version, the area of the premises is halved, but at the same time we slightly expand the steam room – up to the size of 1.5×1.5 at the expense of the rest room. If there is a need to save money, the relaxation room can be neglected, especially if the bathhouse is close to the main building.

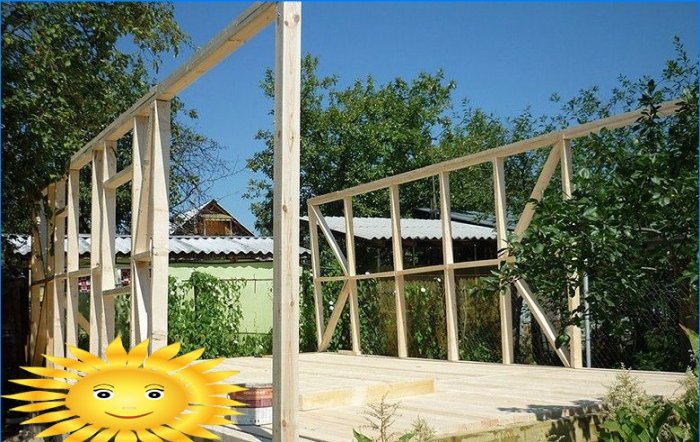

Assembling the frame and walls of the bath

The foundation of such a structure can be a columnar (pile) or shallow tape structure. It is necessary to take care of good waterproofing between the foundation and the beam of the lower strapping: for this, several layers of bitumen are laid, alternating with bituminous mastic.

A frame bath can be erected as a separate building, or it can be closely attached to a brick house. In the latter case, a certain gap should be provided between wood and brick (stone, concrete): otherwise, the walls of the bath will deteriorate. The gap (50 mm wide enough) must be filled with thermal insulation material.

The construction of the bath is based on a rigid frame made of a bar with a section of 150×150 mm. The frame consists of beams of the upper and lower strapping, racks and crossbars (window sill beams). The distance between the pillars should be 0.6 m: the exception is walls with openings for installing doors, where this distance can be increased to 1 m.At the places where windows are installed, corresponding changes are also required: the distance between the pillars increases to the width of the window frame, and under the window a horizontal crossbar is attached, supported by a rack element. A transom board 50 mm thick is also attached above the window. Each wall is first assembled separately and constitutes a frame. The assembly is carried out on a flat area of the construction site. The bars of the lower (basement) strapping should be made of oak: this type of wood is moisture resistant, but additional treatment with an antiseptic is still necessary.

When assembling the bath, the beams and racks are connected with nails. The elements of the lower trim must be connected in the corners and must be supported by the supports. They should have a strictly horizontal position: in case of deviation (detected using a level), alignment is performed using linings made of roofing material folded in several layers or moisture-resistant plywood.

The walls of the frame steam room are assembled in stages: having assembled the first wall, it is installed and temporarily fixed with struts, while checking the verticality of the racks. After installing all the walls, the elements of the lower strapping, except for connecting with nails, are fastened with boards. At the end of the installation of the frame, all corners should be checked: they must be straight.

The next stage is the installation of the cladding. Outside, moisture-resistant plywood or OSB boards are packed. External wall cladding can be done using plaster: first, obliquely placed chipped boards are stuffed over the walls, on top of which plaster shit is attached in the same way. Plaster not only additionally insulates the walls, but also makes them fireproof. Another method of finishing the outer surface of the walls is carried out with the help of metal profiled sheets, but first, at the locations of the racks, beams with a section of 50×50 mm are packed, and sound insulation is laid between them, which is also a heater.

After the installation of the load-bearing walls, a roof is constructed, and the internal space of the bath is divided by partitions into separate rooms for various purposes.

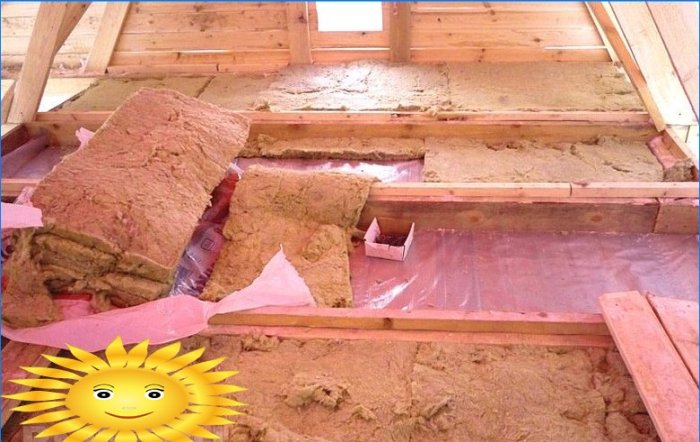

Installation of thermal insulation and vapor barrier of a bath

On the inside, a waterproofing material is attached to the casing, which can be used as a thick polyethylene film. If it consists of several panels, the joints are overlapped and glued with tape. Waterproofing is necessary to protect the insulation (the next layer in the wall structure) from moisture in the outside air. Thermal insulation is carried out with mineral wool. Insulation should not fill the entire space between the walls: a ventilated gap of 40-50 mm is required.

Fiberglass can also be used as an insulating material: it also has a low thermal conductivity. This allows you to build a steam room in which heat will be retained even more efficiently than in a brick bath. In addition, the laid glass wool and mineral wool is also good sound insulation, which is important for the comfortable operation of the room..

In the project of a frame bath, vapor barrier must be taken into account: it should be given special importance. The vapor barrier film must be installed in a continuous, airtight layer. It is important to orient it correctly: otherwise, the effect will be exactly the opposite of what was expected. Vapor barrier is necessary to protect the thermal insulation material from steam generated in the bath in large quantities. Such a film, due to perforation, allows moisture to pass through only in one direction – outward. Due to this, a small amount of moisture, which can still penetrate into the structure of the wall, has the ability to escape..

In addition to the above materials, foamed polyethylene with a foil outer surface can be used for the construction of the walls of the bath: it is placed between the vapor barrier and the heat insulator. The foil will help retain heat by reflecting heat energy back into the steam room..

Insulation of the ceiling and floor

The insulation of the ceiling is carried out from the attic side using the same technology and using the same materials that were used in the construction of the walls. Thermal insulation of the floor in the bathhouse should not be performed at all: it will be better if the underground remains well ventilated. In this case, the boards will last much longer..

Furnace installation, chimney installation

It is worth paying special attention to fire safety: in the place where the chimney exits through the attic floor and the roof, it is not allowed to install a flammable waterproofing film made of polyethylene or other similar material. The pipe should be insulated with asbestos cloth or fireclay heat-insulating bricks. A good way to insulate a pipe is to use a coaxial chimney: its design consists of two concentrically arranged pipes with thermal insulation between them. But additional thermal insulation is still needed: in the area of direct contact with neighboring materials, the pipe should be wrapped with asbestos cloth. Such a solution is also possible with a chimney outlet through the wall..

The cast iron stove can be installed on a pre-built foundation. The walls, floor and ceiling near the stove should be sheathed with sheet metal, placing an asbestos gasket under it.

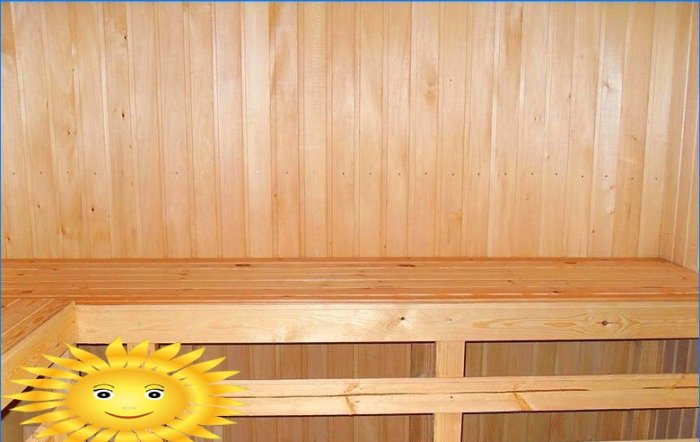

Interior decoration (choice of wood)

For the construction of a frame bath, only well-dried wood should be used. It is necessary that the beams, plywood and material for interior decoration be made of larch, linden or aspen: these species have low thermal conductivity. Thanks to this, heat will be well retained in the steam room, in addition, the structure will retain its geometry..

By the same principle, the lining for the inner lining should be chosen. The panels should be placed vertically, joining together according to the thorn and groove principle. The lining can be treated with linseed oil, but cannot be painted: when heated, the paint can release toxic volatile compounds.

Floor joists and floorboards must be placed at a slight incline to allow water to drain off. A good solution would be to install a wooden font: it will take up little space and at the same time can replace the pool. The steam room will be ready to receive visitors after the benches are installed and the stove is fired up. She is in no way inferior to a log cabin.

I’m curious, what are some efficient and budget-friendly methods for constructing a bath?

Can anyone provide tips on how to efficiently and budget-friendly construct a bathroom? I’m looking for suggestions on materials, design ideas, or any other creative solutions that can help me build a bath area fast and without breaking the bank. Your insights would be greatly appreciated!