Recommendation points

- Requirements for vapor permeability

- Insulation technology

- Goal number 1. Creation of an insulating layer

- Goal number 2. Overlapping cold bridges

- Goal number 3. Filling sinuses, cracks, voids

- Protective films

- Vapor barrier

- Membrane

- Steam outlet or why “soffits” are perforated

The article contains the most effective methods of insulating frame houses. You will learn about the features of thermal insulation technology, the use of barrier films, and the device of a ventilated facade. Also, a comparative table of insulation properties is presented to your attention..

Houses built according to the “Canadian” frame technology have one distinctive feature: the frame of the wall frame creates cavities. The voidness of this element is about 90% and it is reasonable to fill the entire space with insulation. Considering that the frame is assembled from wood and pressed OSB boards, it must continue to “breathe”, since the tree continues to “live” until complete decomposition. However, there is no moisture in a properly assembled frame.

Requirements for vapor permeability

Many materials have thermal insulation properties – from paper to nylon. The main requirement for insulation, especially when it comes to a wooden structure, is vapor permeability. This indicator is indicated by the letter M (mu) and must be no lower than that of the wood from which the frame itself is made. As a rule, houses are built from coniferous sawn timber – spruce, pine. Their vapor permeability along the fibers is 0.32 Mg / (m h Pa).

Vapor permeability of popular heaters

Insulation Water vapor permeability, Mg / (m h Pa) Extruded polystyrene foam 0.013 Expanded polystyrene 0.05 Polyurethane foam 0.05 Expanded clay 0.21-0.26 PVC foam 0.23 Ecowool 0.32 Tow 0.49 Mineral wool density 200 kg / m3 0.49 Mineral wool density 50 kg / m3 0.6 The first five synthetic heaters do not pass according to the indicator M. Their use is associated with the sealing of the insulated plane or structure. Their inability to pass steam is perfectly illustrated by their buoyancy. Remember an important rule – never, under any circumstances, insulate wooden houses with foam and its derivatives. The result can be shockingly unpleasant..

The consequences of warming a wooden house with expanded polystyrene on video

The remaining four participants fit into the M frame > 0.32, but one of them – tow – is not positioned as insulation. Rather, it is a seal with thermal insulation properties. The greatest indicator M is for mineral wool, and for ecowool it is equal to a tree, therefore both types are accepted for consideration.

Insulation technology

With thermal insulation of any design, three goals are pursued, which constitute reliable protection from cold.

Goal number 1. Creation of an insulating layer

This layer can be located both inside the frame and outside the wall (stone or wood). In some cases, they resort to insulation from the inside of the room. The thickness of the layer in the frame walls is dictated by the width of the board adopted for the structural rib. In most cases, this value is in the range from 100 to 200 mm. When designing frame houses, specialists must take into account the method of insulation, since the mineral wool has a standard gradation of 50 mm slab thickness, which means that the internal wall thickness must be a multiple of 50 mm. In the case of ecowool, the wall thickness can be any – spraying is done with a layer of 10 mm.

Goal number 2. Overlapping cold bridges

It is the cold bridges that often fall out of sight of designers. The thermal insulation properties of the material of the construct itself – wood – are confusing. Yes, they are pretty good – the thermal conductivity of pine is 0.09 W / (m · C). But ecowool has 0.032, and mineral wool has 0.07. That is, it is not the absolute indicator that is decisive, but the relative one – the difference in thermal conductivity of the materials from which the structure is composed.

In a frame house, the most numerous cold bridges are racks. They penetrate the entire thickness of the wall. In order to cover them, an additional layer of insulation is arranged, as a rule, 50 mm. This is enough so that the cold does not reach the vertical racks of the frame..

The method of localizing cold bridges in this case does not depend on the type of insulation. In practice, it looks like this: a transverse counter-lattice is mounted from a 50 mm bar with a step of 600 mm (under a mineral wool slab) and filled with slabs or spraying.

Goal number 3. Filling sinuses, cracks, voids

Despite the fact that air itself is a good insulation, during construction or restoration, absolutely all cavities and sinuses must be localized – poured, filled with cotton wool or rendered harmless in another way. The only case where wadded insulation is powerless is in damp places. Decisions on such places are made individually.

Protective films

For excellent indicators of vapor permeability, wadded heaters have to “pay off” – they are afraid of water. Moistened cotton wool does not keep warm, while wet cotton wool sticks together and cannot be restored. In order to prevent this from happening during operation, two types of protective films are used.

Vapor barrier

Most readers will say that everything is clear here, it must be installed on both sides, but this error occurs in up to 40% of cases of using films. Vapor barrier is a sealed material that does not allow steam and moisture to pass through. This barrier should be located only from the inside so that the vapor of air saturated with moisture (from breathing) heated by heating does not penetrate into the insulation and do not spoil it. As this film, you can use ordinary polyethylene if it is non-toxic and suitable for indoor use. The use of paroizol from the outside will lead to the fact that the cotton wool will not be able to release humidified air into the atmosphere and will become wet. Slowly but surely, the insulation will stop working, and the frame will begin to damp.

Membrane

The full name is superdiffusion membrane. It is a material with a powerful microscopic capillary pump that pushes moisture (vapors) in one direction. Being outside, it removes moisture from the cotton wool without letting anything back through. This phenomenon is especially true in the fall, when the house has been unheated for some time (several days), the frame and insulation are saturated with atmospheric moisture. Then the house starts to be heated, the vapors are activated by heating and require an exit. The membrane gives them this opportunity.

The consequences of improper use of vapor barrier (polyethylene) are clearly illustrated by the video

Steam outlet or why “soffits” are perforated

The excess heat that the walls pass through themselves during the period of intense heating must evaporate somewhere. In other words, mix with atmospheric air. In most cases, wooden “frame frames” are sheathed outside with a light ventilated facade – clapboard, block-house or siding panels. The lathing for outdoor decoration must be vertical. This is necessary for the formation of vertical “corridors” through which the warmer air will freely rise upward and erode through ventilated soffits.

The place where the spotlights meet the wall must be free for air passage. In this case, there should be no air vent from below, otherwise a draft will form. If the crate is made horizontal, the air movement will be difficult or completely blocked. In this case, the concentration of moisture on the wall will increase..

Practice has shown that problems with improper insulation of frame houses are in second place in mass after assembly defects. In most cases, these problems can be corrected, but this is due to the complete or partial (30–70%) replacement of the insulation. This procedure will entail a major overhaul of the premises. At advanced stages, the formation of fungus on the wood of the frame and rotting is possible. Therefore, adherence to the simple rules given in this article will help you avoid major problems with the insulation of your frame house..

What are the different materials, methods, and technologies available for thermal insulation in frame houses?

There are various materials, methods, and technologies available for thermal insulation in frame houses. Common materials include fiberglass, mineral wool, cellulose, and foam boards (such as expanded polystyrene or polyisocyanurate). Each material has its own R-value, which measures its insulating effectiveness.

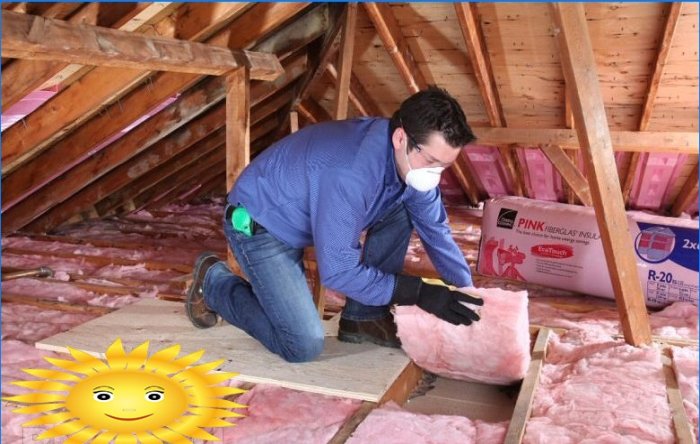

The methods for thermal insulation include cavity wall insulation, where insulation is inserted into the gaps between the wall studs, and continuous insulation, which involves wrapping the entire house in insulation. Another method is insulating the attic and roof, as heat tends to rise and escape through the roof.

Technologies used for thermal insulation in frame houses include spray foam insulation, which is applied as a liquid that expands and solidifies, providing a seamless and airtight insulation barrier. Additionally, reflective barriers or radiant barriers can be installed to reflect heat away from the house, particularly in hot climates.

It’s important to consider the specific requirements and climate conditions when selecting the appropriate materials, methods, and technologies for thermal insulation in frame houses. Consulting with a professional or energy efficiency expert can help determine the most effective solution for maximizing energy efficiency and reducing heat loss or gain in the house.

What are the most commonly used materials, methods, and technologies for insulating frame houses? Are there any specific factors that should be considered when choosing insulation for frame houses? Is there a recommended thickness for insulation to ensure optimal thermal efficiency?