Recommendation points

- How the load is calculated

- Jumpering in stone buildings

- Strengthening openings in frame buildings

- How to make and strengthen openings in load-bearing walls

The device of openings is a rather delicate topic; more than one builder stumbled over this stone in his practice. Today we will share information on how to calculate and install lintels for window and door openings, depending on the type and material of the walls..

How the load is calculated

Technically, the lintel in the upper part of the opening is an ordinary beam and the calculation for it is carried out in the same way. There are two main requirements that this part must satisfy:

- The sections of the walls on which the lintel rests must adequately perceive the load.

- Residual deformation (deflection) of the lintel under load should not exceed the permissible values for windows or doors installed in the opening.

The self-supporting properties of the wall must always be taken into account. Very often, when erecting masonry, opening lintels perform their function only for the first 2-3 weeks after their installation, and then simply remain in the walls unnecessarily. This applies to those openings over which a pillar of masonry is preserved, in height equal to the length of the span. Here, a jumper is not needed at all – the wall will support itself, while the larger the blocks used for masonry, the lower the height of the pillar should remain.

In other cases, the calculation of the jumper is based on the applied load, including:

- own weight of the lintel;

- the weight of the wall, taking into account the self-supporting capacity (the height of the masonry above the opening);

- distribution of wall weight (for summer masonry, only 1/3 of the width above the opening is taken into account, for winter – the entire wall is completely);

- load due to the support of beams or floor slabs on a given section of the wall.

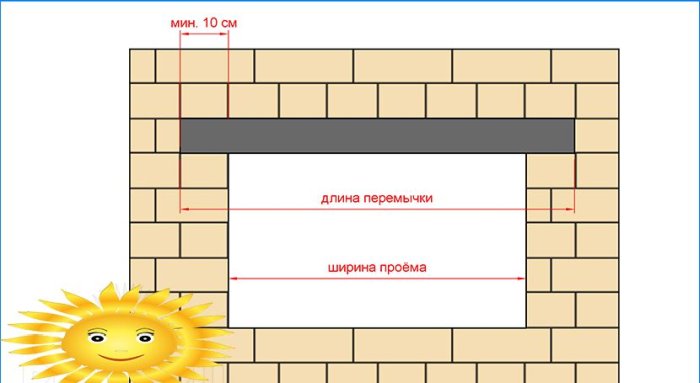

The linear dimensions of the lintel are also important. Its width is determined by the thickness of the wall, and its height is determined by the required bearing capacity. The length of the lintel corresponds to the width of the opening plus twice the value of the depth of occurrence: from 10 cm for brick walls and up to 30 cm for loose porous blocks.

In most cases, to determine the appropriate lintel, it is sufficient to select from tables with standard factory-made precast concrete elements (1.038 series for standard and 1.225 for very wide openings). The required product is determined by the width of the opening, taking into account the depth of the bookmark. If the sought-for jumper is thinner than the wall, you need to install several of these, well, or at least two pieces.

Of course, no one insists on purchasing finished products. You are free to cast reinforced concrete lintels yourself, as well as replace them with wooden or steel ones at your discretion, having previously calculated the lintel for deflection.

Jumpering in stone buildings

The easiest way to decorate the upper part of the opening is to avoid using a lintel by increasing the height of the window up to the armopoyas itself. This is not always possible, because the length of the span imposes its own restrictions, especially for load-bearing walls, and besides, it is impossible to bring the doors to the very ceiling. And yet you should know that between the opening and the reinforced crown there should be at least two rows of large-format blocks, or 5-7 rows of bricks, or there should be nothing.

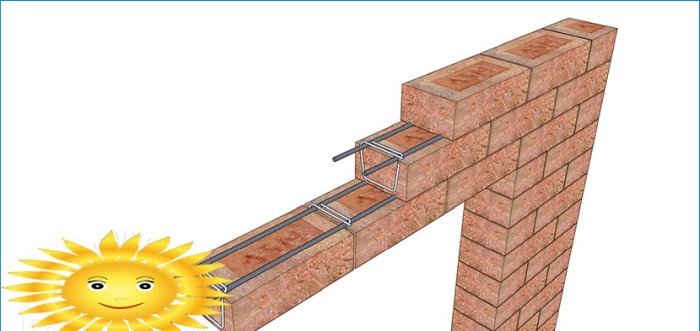

The easiest way is to arrange the upper part of the opening in the walls, on which the ceilings do not rest. If the height of the masonry above the opening does not meet the requirements for self-support, the upper rows are reinforced with reinforcement. Between each brick of the row covering the opening, “paper clips” are laid – clamps of 4 mm wire, which protrude above the row of masonry, forming a kind of ears. Longitudinal reinforcement is inserted and tied under them, one 10 mm rod for every 10 cm of wall thickness, letting 15–20 cm on the pillars on the sides of the opening.

It is even easier to reinforce the opening in load-bearing walls made of solid lightweight concrete blocks. The masonry above the opening is brought out using a temporary support from the bottom. After that, a groove up to 20 cm deep and 25–30 mm thick is cut in the center of the blocks above the opening. A flat reinforcement is inserted inside – a mesh of 12 mm reinforcement, and then the groove is filled with sand concrete. If it is clear that such a strengthening does not meet the strength requirements, use U-shaped trays made of porous concrete in the manner of a permanent formwork.

Reinforced concrete lintels are very essential cold bridges. Their use is required only in exceptional cases, when a very wide opening is planned in the bearing wall. Such lintels are cast flush with the wall, knocking out the panel formwork from the inside, outside and below. The lintels are reinforced in two rows, one 12 mm rod for every 60–80 mm of wall thickness. Depending on the span length, 2-3 more reinforcement bars can be added to the bottom row of reinforcement. To exclude heat migration, a pair of EPSP plates with a total thickness of 50-70 mm are installed in the center of the formwork, while the reinforcement is distributed to obtain protective layers of 40 mm.

When installing jumpers of any type, it is important to be able to properly prepare the “shoulders” on which they rest. As a rule, wood, solid brick or cement mortar of grade 300 are used for this..

Strengthening openings in frame buildings

For a frame building, the presence of jumpers in the upper part of the openings is strictly necessary. The requirements described below are valid for both metal and wood frames..

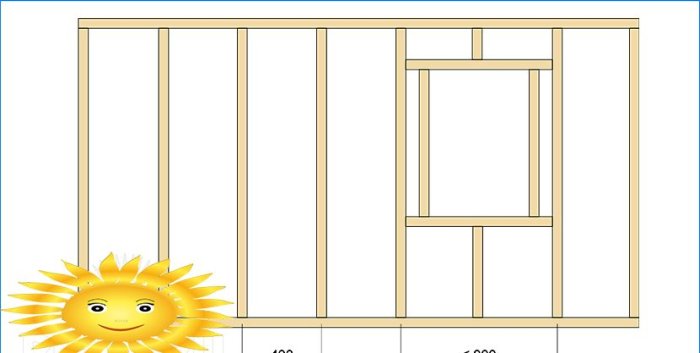

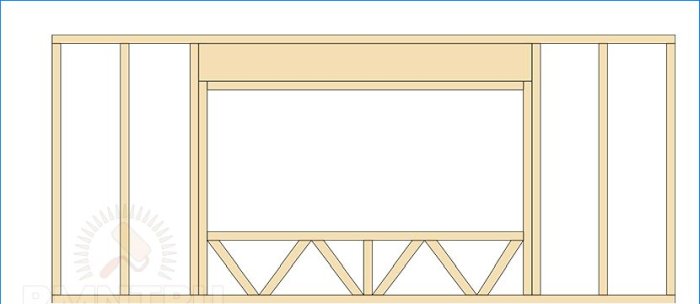

If the width of the opening does not exceed two steps of installation of the frame racks, the nearest side rack elements are connected by two horizontal crossbars, and then two vertical spacers are added between them, setting the required opening width.

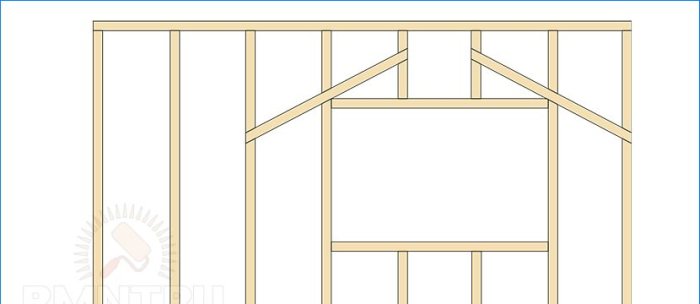

If the opening in width is equal to three or more distances between the frame posts, it is decorated with crossbars in the same way. For additional support of short struts above the opening, they are unloaded onto adjacent ones using diagonal braces extending from the center outward. In all cases, the cross-section of the crossbars should not be less than the size of the rack-mount elements of the frame.

If the opening exceeds five times the distance between the posts in width, the verticals nearest to it should be doubled. The inner pair is connected by a horizontal jumper, and the outer one is the same, but higher by half the opening height. The space between two horizontal beams is filled with a diagonal stiffening grid according to the principle of floor trusses.

How to make and strengthen openings in load-bearing walls

When redeveloping, it may be necessary to make an opening in the load-bearing wall. Similar actions in the communal sector can only be carried out in agreement with the housing stock, while private developers can act at their own peril and risk..

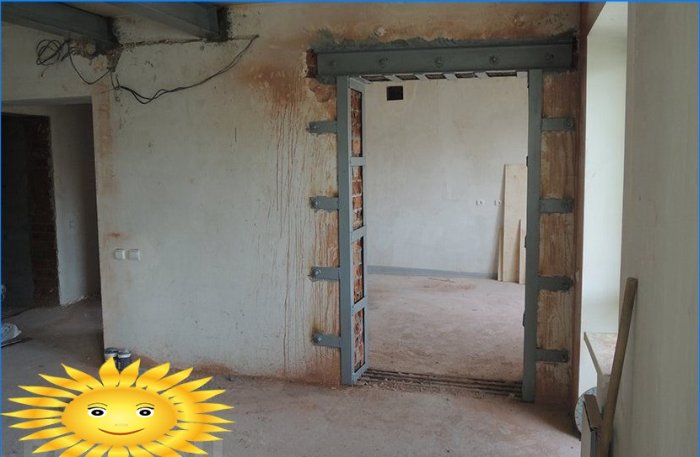

According to the project, the boundaries of the future opening are marked on both sides of the bearing wall. To make sure of complete coincidence, after marking on one side, four strictly perpendicular holes are drilled in the corners of the opening and connected with lines.

Along the upper border of the opening, a horizontal trimming is carried out with a width of about 10 mm and a length of 20 cm more than the opening in both directions. A piece of angle steel is laid in the resulting groove on each side. Its section can be determined by the calculation for bending, but more often mortgages are made with a large excess strength. In general, a steel angle 100x100x8 mm will be more than enough.

Above the nested corners, one hole is drilled for every 25 cm of the opening width, smooth reinforcement is inserted into them, through which the corners are connected to each other. The lower bundle is made of overhead steel plates 100×8 mm. After installing the lintel, the opening can be cut and removed in fragments..

In the lower part of the opening along the plane of each wall, two pieces of angle steel with dimensions of at least 50x50x4.5 mm must be laid. They must be brought into the wall at least 50 mm on each side. Vertical side corner covers are inserted between the lower and upper corners. In size they are usually chosen to be equivalent to the top border..

From the inside, the side corners are tied with overhead plates. In the wall, the strapping is fastened with pins of 12 or 14 mm of profile reinforcement, which are hammered into holes drilled at an angle of 45 ° to the plane of the wall every 35–40 cm. The pins are attached to the corners by welding, cut to 60–70 mm, and then tightly are bent to the plane of the frame and carefully scalded.

I’m interested in making jumpers for my window and door openings. Can anyone guide me on how to calculate the measurements accurately? Also, is it feasible to manufacture them myself, or should I consider professional help? Any advice or resources would be greatly appreciated. Thanks!

Can someone provide guidance or recommend resources for calculating and manufacturing jumpers specifically for window and door openings? I’m interested in attempting a do-it-yourself project and would appreciate any advice or tips. Thank you!