Recommendation points

- Design work

- Taking measurements

- Drafting a fire escape

- Picture of detailed construction drawings

- Counting the amount of material and tools required

- Making stairs

- Ladder installation

A fire escape is an important element of building security, which is necessary for tall buildings. In this article, we will consider the independent manufacture of a structure for a two-story house, which will cost from $ 100, starting from the project and drawings, and ending with the installation of the structure.

Design work

Taking measurements

It is necessary to measure the height of the building wall from the ground to the roof, as well as to obtain the dimensions of the protruding parts of the house, baseboards. It is important to take into account the material from which the wall of the object is made, to which the structure will be attached, to determine the thickness of the insulated layer.

Drafting a fire escape

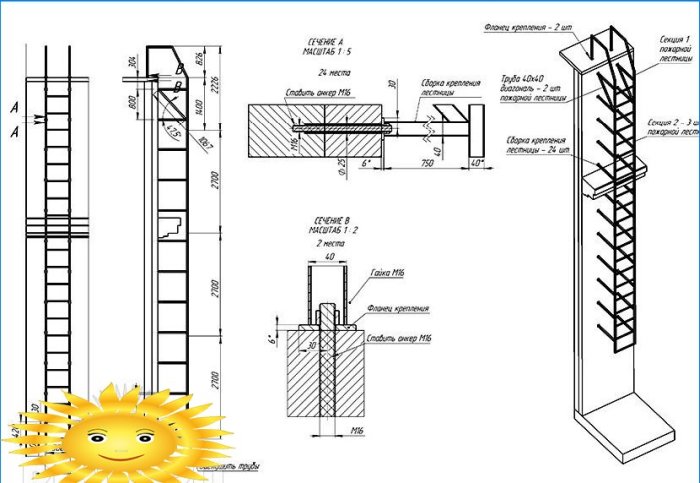

Picture of detailed construction drawings

Section 1 – 1 piece.

Section 2 – 3 pieces.

Ladder mount assembly – 24 pcs.

Mounting flange – 30 pcs.

Counting the amount of material and tools required

For the manufacture of metal structures, you will need the following materials, standard elements:

- pipe 30×30, steel St3 – 15 m;

- pipe 40×40, steel St3 – 24 m;

- sheet 6 mm, steel St3 – 500×300 mm;

- pipe Ø25 mm, steel St3 – 5 m;

- anchor М16 – 30 pcs .;

- hairpin М16, c / b – 8 m;

- nut М16, c / b – 30 pcs.

Necessary tools and equipment to create a ladder:

- Bulgarian;

- cutting discs;

- cleaning discs;

- welding machine;

- electrodes;

- puncher;

- drill for anchor M16;

- drill;

- drill for metal Ø17 mm;

- water level (laser);

- roulette;

- marker;

- primer for metal;

- putty;

- paint;

- silicone sealant.

Determination of the cost of manufacturing a structure:

- materials and standard parts will cost $ 40;

- consumable tool will cost (not including grinder, hammer drill, drill and welding machine) $ 60.

Total cost of manufacturing the structure: $ 100.

Making stairs

- Cutting material, creating blanks. The pipes are cut into the necessary parts using a grinder and cutting wheels. Flanges are prepared using a grinder with discs and a drill with a drill.

- Manufacturing of welding units. Sections of the future staircase are created. To do this, you must have a flat surface. The pipes are connected to each other with tacks, the size is checked, then the elements are completely welded.

- Pre-assembly of the structure. Sections are connected on tacks. Compliance with the dimensions according to the project is controlled.

- Cleaning and priming of assemblies, parts. The sections are disconnected. Irregularities in the weld seams are smoothed out with a grinder with scraping discs, rust, burrs, and scale are removed. All parts and assemblies are primed for metal.

Ladder installation

- Marking of attachment points, checking heights. The dimensions of heights and protrusions are taken again. To make sure that the prepared work is correct (if there are errors, it is better to eliminate them before starting installation). The structure is tried on in stages, the places of installation of the anchors are marked.

- Installation of embedded elements. Using a hammer drill with a drill in the wall of the house, the places for fastening the anchors are prepared. Embedded elements are installed with adapter tubes ø25 mm. Roof joints, walls with fasteners are sealed (to prevent the negative effect of moisture on the house).

- Assembly of assembly units. Flanges are fastened with studs and nuts. Distance pipes 40×40 are welded to them, and sections are welded to the pipes.

- Final construction welding. The design dimensions, the location of the structure in the levels are controlled. Elements are scalded. Seams are cleaned, irregularities are removed.

- Putty, painting stairs. Welding places are primed. The structure is putty and painted.

A fire escape is a simple but necessary structure for a building. It allows you to eliminate fires on the roof, attic, second floor, etc. in the shortest possible time, keeping the rest of the house intact.

What are some important considerations and guidelines one should follow when designing and constructing a fire escape for a two-story house?