Recommendation points

- Types of reinforcement and their purpose in the foundation

- Rebar content standards

- Types of loads

- Assembly of reinforcing cages, types of materials

- How to knit basic spatial designs

- Rebar laying, fixing and protection.

From the beginning of the design to the completion of installation, special attention is paid to the reinforcement, because it is she who gives the tape the required structural qualities. We propose to consider the physics of the model of a reinforced concrete beam in order to understand the basic rules for calculating and installing a reinforcing cage.

Types of reinforcement and their purpose in the foundation

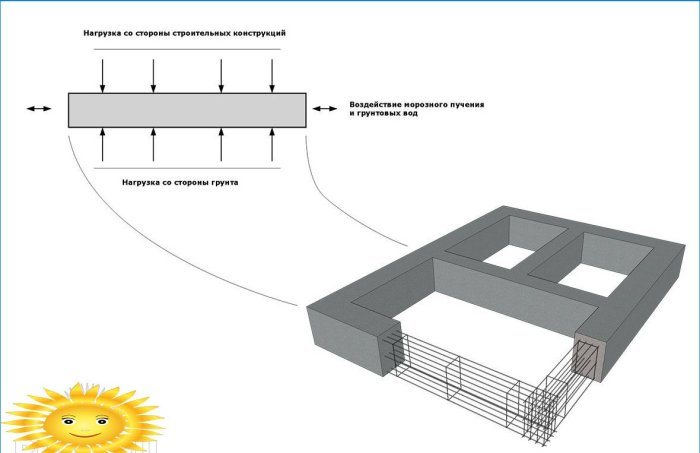

A strip foundation can be represented as a beam to which a series of distributed loads are applied. In addition to increasing the supporting section of the building, the foundation provides the necessary rigidity of the base for the walls, therefore, it must have certain strength parameters in different linear directions. This need arises due to the heterogeneity of the soil: where it is denser, the load becomes concentrated, multiple overvoltage of the structure occurs.

Many people know this principle, but not everyone knows that one type of valve cannot perform so many tasks. The reinforcement is classified according to the function of participation in the work of the entire structure into three types, but it is far from the fact that all of them will be present in a single foundation. Most of the work is performed by the largest reinforcing bars, which are predictably classified as working reinforcement. Its main task is to resist tensile deformations so that the opposite edge of the tape experiences an internal compressive load. The high compressive strength of the concrete compensates for the tensile load, which always remains within acceptable limits. The compressible layer is always located on the side of the applied force.

Linear reinforcement is insufficient where the beam length is too long or axial compressive loads are applied. The reinforcement works well when stretched in a straight line, but when bent, axial stiffness is lost. In order for the frame to remain monolithic, and its elements are correctly located in the section of the product, the rows of working reinforcement are connected with structural reinforcement. It is usually of a thinner section and is almost always located across the main.

1 – working fittings; 2 – structural fittings; 3 – embedded elements; 4 – concrete preparation

Strip foundations are rarely linear, with the exception of foundations for building fences. Usually it is a closed spatial figure, sometimes with radial projections. Also, the foundation may not be cast immediately, while when connecting individual parts, it is required to observe the nominal strength. Fastening of different beams at abutments and joints is provided by embedded elements, anchoring reinforcement, which is bent and welded elements of the same diameter as the working rods.

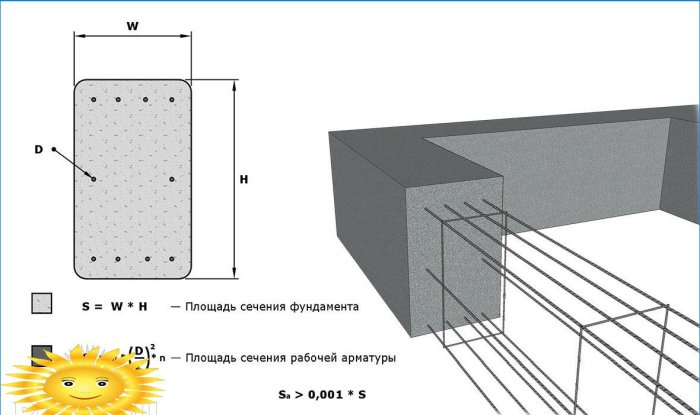

Rebar content standards

Knowing that the reinforcement prevents linear deformations, it can be reasonably assumed that for a high-quality performance of the task, its amount should be proportional to the amount of concrete used. For strip foundations, the minimum reinforcement content is standardized at 0.1% of the total section of the beam.

However, the minimum cross section is rather a check card, in practice, the reinforcement in the foundation always contains more than 0.1%. This ensures a margin of safety and resistance to secondary, concentrated and indirect loads. For example, a tape of 300×1000 mm is thin and high, the content of reinforcement in it should be at least 300 mm2, which is equivalent to four rods of 10 mm or six of 8 mm. But even visually, a frame with so much reinforcement will be too weak..

But if you add 2–4 bars, then there is a possibility of full reinforcement of the upper and lower edges or a device of normal distributed reinforcement. An additional benefit of distributed reinforcement is the increased adhesion of the bars to the concrete, but the elements themselves should not be too thin to meet the existing load class.

Types of loads

The main load on the foundation is in the vertical direction, both from the side of dense soil and from the side of the building structure. The working reinforcement is located perpendicular to the load vector. The latter may have a direction other than strictly vertical, which is determined by the peculiarities of the geology of the construction site.

Of the additional loads, the lateral load is most pronounced, arising from the heaving of the soil and the onslaught of groundwater in the flood. For beams with a width-to-height ratio of more than 1: 3, additional reinforcement of the side walls, usually internal, is required. In fact, one central line of reinforcement or a spatial mesh with a cell of 0.5–0.7 m is sufficient. The thickness of the rods may be less than the nominal.

Tearing loads can occur on foundations with complex cross-sections (T and H), which act on the protruding parts (shelves). To compensate for such effects, complex L- and C-shaped anchors are used, in shape repeating the cross-section of the beam. In such cases, additional reinforcement (anchoring) can serve as structural reinforcement..

Remember that a frame correctly distributed in space is much more useful and profitable than a senseless and in no way ordered laying of increased portions of reinforcement. Fortunately, it is very simple to form the frames of concrete tapes, because usually these are the simplest spatial figures with quite obvious mechanics of work.

Assembly of reinforcing cages, types of materials

To date, reinforcing cages are practically not assembled locally. Everything is knitted on the surface in convenient conditions, then individual modules are installed in the formwork and fastened together. Fastening is performed with a viscous annealed wire 1–1.5 mm thick. Welding is rarely used and not with all types of fittings, often such a decision must be justified by special reasons. Knitting is much more profitable in terms of speed: with the right tool and technical knowledge, one connection takes 5-7 seconds versus 30-40 seconds in the case of welding.

There are six classes of fittings, designated by the letter “A” and a Roman numeral. The higher the class, the higher the strength and the lower the yield strength of the steel (elongation before breaking); there are also differences in the section. The first class is absolutely smooth reinforcement of a round profile, the second class has protruding ribs located by coiling, and all the older ones have a herringbone. The “T” index in the marking denotes thermally hardened fittings, the “C” index – suitable for welding.

For convenience and accuracy of work, the rods of the working reinforcement are fixed in a template, which retains their spatial position until the assembly is completed. Working reinforcement is carried out with reinforcement of class A II and older, depending on the design requirements. According to the table of correspondence of diameters and the number of rods to the total section, the optimal distribution of the minimum allowable content of reinforcing elements is selected.

If it is necessary to compensate for the torsion and bending loads across the axis, a transverse one is tied to the longitudinal working reinforcement, forming a spatial mesh. Between each other, different lines of working reinforcement are fastened by binding to clamps, usually encircling the working reinforcement on the outside. For structural distribution reinforcement, it is customary to use reinforcement of classes A I and A II.

How to knit basic spatial designs

The principle of reinforcement distribution is easiest to understand with specific examples. Consider a rectangular beam with a width and height of 40 and 110 cm. According to the correspondence table, for reinforcement, you need to use either four rods of 12 mm, or six of 10 mm, or nine of 8 mm. With such dimensions of the foundation, it is most reasonable to use 10 mm reinforcement, the thickness of which should be proportional to the dimensions of the product.

The aspect ratio is less than 1: 3, that is, additional reinforcement of the vertical edges is performed at the discretion of the developer. Reinforce two planes – the upper and lower, the rods should be spaced from the surface of the product by the value of the concrete cover, but not too close to the center so as not to go beyond the limit of perception, and not too close to each other so as not to create obstacles to concrete flow.

With a protective layer of 60 mm, we can place four rods of 10 mm, keeping a distance of about 90 cm between them. Accordingly, the crushed stone should have a fraction of no more than 35–40 mm. Each line of reinforcement can be made spatial, for example, by vertically shifting the bars located in the center, or in a checkerboard pattern. But in this case, two standard sizes of structural reinforcement are required. One for linking individual lines and one for connecting the frame together.

This is the case with complex foundations. Their section is divided into a series of rectangles or trapezoids, which are connected to each other using clamps. For example, for a T-shaped foundation with the dimensions of the lower horizontal foot of 30×100 cm, it is possible to reinforce with a mesh of four longitudinal rods of 10 mm each and transverse inserts every 40-50 cm of the same section. The vertical beam is reinforced like a regular tape, but the bottom edge is not reinforced, instead the longitudinal bars are evenly distributed along the vertical section.

Rebar laying, fixing and protection.

Segments of linear sections of reinforcement with the same arrangement of working reinforcement are connected with an overlap of 30 to 50 nominal diameters, depending on the adhesion of concrete. The ligation of the twigs folded in parallel is performed every 25-30 cm with wire clamps.

Segments of the frame with intersecting working rods are connected with bent anchors. Their cross-section should be the same as that of the working rods; with different thicknesses of the rods, preference is given to the larger of the diameters. The overlap in the dressing is from 50 to 80 diameters, depending on the spatial arrangement and the effect of the lever of the acting loads.

The frame must be distanced from the bottom of the formwork. For this, hollow plugs or sleeves made of polyethylene pipes are used. Sometimes it makes sense to arrange preparation with concrete with a strength grade of M100 or M150, lay reinforcement on it and then, after hardening, mount the frame and carry out the rest of the pouring. This technology must be consistent with the location of the “cold” joint, which is a weak point in the waterproofing.

The frame is expanded from the walls either with plastic rods or other non-rotting and hydrophobic material. Rigid spatial anchoring is necessary to maintain the required value of the protective layer – from 40 to 70 mm. Violations and shears can bring the reinforcement too close to the surface layer in which there is gas exchange, or bend it. This has an extremely negative effect both on the rigidity and strength of the product, and on the resistance of reinforcing steel to corrosion. To increase reliability, the frame can be fixed with temporary rods, which are removed after complete pouring of concrete.

Could you please provide information on how to calculate the reinforcement for strip foundations? Additionally, I would like to know the proper technique for knitting and laying the reinforcement frame. Thank you.

Could you please provide more information on how to calculate the reinforcement for strip foundations? Additionally, could you explain the process of knitting and laying the frame for strip foundations?

To calculate the reinforcement for strip foundations, one must consider the load-bearing capacity of the soil, the dimensions of the foundation, and the anticipated loads. A structural engineer typically performs calculations using relevant design codes and engineering principles.

When it comes to knitting and laying the frame for strip foundations, it involves a few steps. First, the steel bars are cut and bent according to the required design and reinforcement calculation. The reinforcement layout is then prepared on the construction site, ensuring the steel bars are properly arranged in the foundation trenches.

Next, the bars are tied together using binding wires or mechanical connectors at the intersections, forming a rigid framework. It is crucial to correctly space and align the bars as per engineering specifications to provide sufficient strength to the foundation.

After the frame is securely knitted, it is laid into the foundation trenches, ensuring that proper concrete cover is maintained. The reinforced frame is positioned at the desired depth and secured in place using supports and spacers. The trenches are then filled with concrete, enveloping the reinforcement entirely.

Finally, the concrete is compacted and leveled to eliminate any voids or air pockets. The concrete mix should be of appropriate strength and workability to ensure the desired structural integrity of the strip foundation.

It is important to note that these processes require professional expertise and should be carried out under the supervision of qualified engineers and construction personnel to ensure the safety and reliability of the strip foundation.

To calculate the reinforcement for strip foundations, you need to consider factors such as the load the foundation will bear, the type of soil, and the dimensions of the foundation. Typically, the reinforcement is calculated based on the design drawings and specifications provided by a structural engineer.

When it comes to knitting and laying the frame for strip foundations, the process involves placing the reinforcement bars in a grid pattern to provide strength and stability to the foundation. The bars are typically laid in two layers, with the top layer being placed perpendicular to the bottom layer. This helps distribute the load evenly and prevent cracking.

Once the reinforcement is in place, the foundation is then filled with concrete, ensuring that the bars are fully covered and secured in the concrete. The knitting and laying of the frame is a crucial step in the construction process, as it determines the overall strength and durability of the strip foundation.