Recommendation points

- How marl became a building material

- What is marl masonry

- Features of working with marl walls

- Plaster walls

- Warming

- Armopoyas

- Openings

- Roof

The article discusses the technology of working with marl walls. You will learn how to properly plaster, insulate and protect marl. Also in the text there is a method of cutting an opening in a marl wall. We will tell you about the features of the operation, repair and construction of buildings built more than 50 years ago.

Margel is a raw material for the production of Portland cement. In order to become this priceless mineral astringent, marl literally has to go through fire and water – it is ground, burned, baked and mixed with reagents. According to the mountain classification, it is sedimentary rock, calcareous or dolomite. In total, there are 12 main types of marl, which are used as raw materials. It can occur in various forms – from a continuous layer to a powdery mass.

How marl became a building material

In the spontaneous development of the private sector of the 40-80s of the last century, many materials were used as raw materials for walls and foundations – from heavy-duty sandstone to substandard brickwork and all kinds of fancy mixtures of sawdust, clay, straw, lime, chips and sometimes cement. The disorderly construction was associated with the need to urgently settle the workers of the new factories of the post-war period – while they were “built” next to the enterprise (closer to work). People used absolutely everything for their homes, including waste, rejects, screenings, dumps, slags and raw materials, which at that time were practically free..

Margel was not of particular value to industrialists – in order to obtain useful material from it (cement, lime and other binders), long-term energy-intensive processing was necessary. Moreover, he was an accompanying material in the extraction of clay, which went to brick factories. Therefore, it was handed over to people without any problems, who learned how to build fairly stable buildings out of it. People used clay as a joint filler – it was convenient, since both materials were extracted literally in the same quarry. We will consider another reason for using clay below..

What is marl masonry

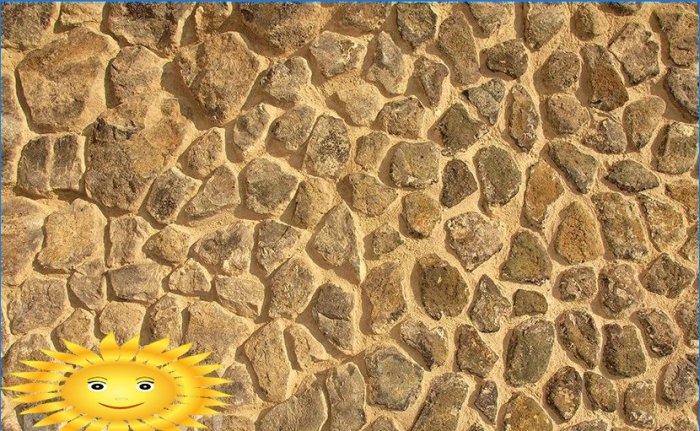

Marl suitable for walls are large stones (the size of a soccer ball) and small boulders (3-4 balls) of a natural shape. There is a lot of lime and chalk in the composition of this stone, therefore it is rather loose – in the modern classification by strength, it will take place between foam concrete and aerated concrete. The stone is drawn with a nail, knocked down with a pickaxe, drilled, easily processed with metal.

Masonry mortar was usually made by mixing clay with fine straw, shavings, sawdust. Because of chalk and lime, the surface of the stone is loose, sometimes dusty, so the use of relatively expensive binders (such as cement), compared to free clay, was not justified. The cement mortar simply does not adhere to the non-porous marl surface.

This combination of the weak properties of the stone and mortar gives the corresponding result – due to the almost complete lack of adhesion between the stones, the integrity of the masonry can only be preserved due to the static. Therefore, the minimum thickness of the marl wall is 500 mm. When laying, the contact planes were only slightly leveled with a pick. Bandaging the corners in this case is impossible, so they were created from brick or cinder block.

Over time, the marl began to be processed in factories, simply by sawing it from all sides to the form of a full-fledged wall block. This made it possible to abandon foreign corners and today you can see four-storey buildings made of marl. Placed on clay, it has good thermal conductivity – about 0.1 W / m K

Features of working with marl walls

The lack of pores and loose clay make it difficult to decorate and restore marl houses. However, often such houses are still quite strong and suitable for use..

Plaster walls

The main feature of marl walls is that they do not hold cement mortar. Due to the weakness of the clay, it is possible to “stick” in the masonry only to a static stone that has no adhesion. There is only one way out – dry fastening of the mesh to the stone with a dowel and fixing the mesh. The more often the plane is dubbed, the better the quality of the plaster will be. Remember that the layer of mortar does not hold to the plane of the wall, as is the case with bricks and cinder blocks, but to the mesh fixed to the dowel. The most popular and effective way of plastering marl is to spray a “coat” from a solution with slag. “Fur coat” perfectly removes moisture from the walls.

Warming

100% natural marl walls are vapor permeable. The use of PPR or foam leads to the effect of a thermos, when the dew point shifts into the wall and the condensate is not removed. The best option is stone or ecowool.

Sealing marl walls is unacceptable – moisture will soak the clay and boulders will simply slide off. The ingress of atmospheric water into the wall can lead to unforeseen consequences, up to destruction.

Armopoyas

This smart way to extend the life of a home is very relevant for this type of building. Usually, during their construction, the armopoyas was made of bricks on cement mortar. As a result, he did not hold the perimeter of the walls, but only distributed the load from the roof.

One of the mandatory stages of reconstruction of houses from marl is a monolithic reinforced concrete armored belt. Moreover, the top of the wall should be cleaned, and then drilled in the visible stones holes O 6–12 mm and 50–60 mm deep and carefully hammered in the reinforcement rods, and then tied with the armopoyas frame. This technique will give up to 15 years of increasing the life of the walls..

Openings

Metal is traditionally the most efficient and expensive material in construction. Due to the inaccessibility of building materials, lintels made of steel profiles were far from being in every private house. They were replaced with wood.

Another popular structural reinforcement is the combined load-bearing door frame. In a log (Ø 80–120 mm), one plane was cut – the profile of the door frame. From three such logs, a U-shaped structure was assembled, capable of taking a load. At the same time, after installation, it looked like an ordinary door frame..

If the need arose to create an opening in the marl wall, you need to act very carefully – the stones easily move out of place. Operating procedure:

- Mark the boundaries of the opening outside the building.

- Drill holes in the upper corners (as accurately as possible) or transfer the marks of the upper line to the inner plane of the wall (hydraulic level).

- Cut to the maximum depth the upper horizons of the opening with a margin of 300 mm on the wall.

- Install a jumper in the slot – corner 75×75 or 100×100.

- Cut the perimeter of the opening with a disc over the stone to the maximum depth. Cut into “cells” the inner area of the opening.

- Gently knock down the “cells” with a hammer and chisel.

- Next, gradually cut through the wall and knock down with a chisel, being outside the building.

- After passing the opening, weld the corners together. If possible, reinforce the opening with a steel clip and plaster on the fixed mesh.

Roof

Enemy number one of the marl walls is the atmosphere. Lime in the composition of the stone actively reacts with oxygen (including in the composition of water) and infrared rays, the material is oxidized and decomposed. The stone left in the open air completely disintegrates in two full seasons. Marl, protected from moisture, wind and sunlight, is perfectly preserved.

It is customary to make hip truss systems on such walls, because they distribute the load better. The larger the roof overhang, the better the wall material is protected from destruction.

If it so happens that you have to deal with a house made of marl, do not rush to worry or refuse. In all cases, only one criterion is of decisive importance – the state of the house at the moment. If the walls are dry and even, there are no serious deviations from the vertical and distortions, the building may well serve faithfully for more than a dozen years. The cost of marl houses is close to frame houses and an order of magnitude lower than full-fledged stone ones.

What are the specific features of repairing and maintaining marl houses in construction?

What are the key features and considerations for repairing and maintaining marl houses in construction?

Marl houses, made from a mix of clay and lime, require specific maintenance and repair considerations. Key features to keep in mind include monitoring the exterior walls for signs of wear or damage, such as cracks or dampness that could indicate water intrusion. It is essential to use breathable materials for repairs to prevent trapping moisture within the walls. Regularly inspecting the roof for leaks and ensuring proper ventilation to prevent mold growth is crucial. When repairing, matching the original materials and techniques is important to maintain the historical integrity of the marl house. Proper drainage around the foundation and ensuring the walls are properly sealed are also vital considerations for maintaining a marl house in construction.