The classic, most common type of wooden staircase is two obliquely inclined stringer beams (straight, rounded or jagged) with steps attached to the top of the beams. This type of ladder has been tried and tested for centuries and is durable and reliable. Disadvantages: large weight of the structure, the need for a large area (depending on the size of the stairs).

A no less popular type of ladder made of wood is with bowstring fastening. A staircase of this design always serves as a decoration for the house and is located in the central hall or living room. Under the staircase space, you can make it closed and get a room usually used as a storage room. The disadvantages of such a staircase are similar to a wooden staircase on kosoura, the design of both types of stairs must be taken into account even when designing a house – they are bulky and massive.

The steps of the staircase, fixed to the bolts, turn it into a cantilever staircase – this type of wooden staircase is the most modern today. Still – a staircase without visible supports, without railings looks absolutely amazing! True, going up and down it is a little scary, it is difficult to get rid of the feeling that the steps will collapse under the weight of someone walking along them. It should be noted that each step can freely withstand a load of several hundred kilograms, its attachment to the wall is reliable. Among all the other types of stairs, it is as easy as shelling pears to clean a staircase, it has no corners at all – places where dust usually accumulates. It takes up little space and is practically invisible. The disadvantage, in my opinion, lies in its airiness – I would nevertheless provide a cantilever ladder with a handrail for greater confidence in my own safety when descending / ascending along it.

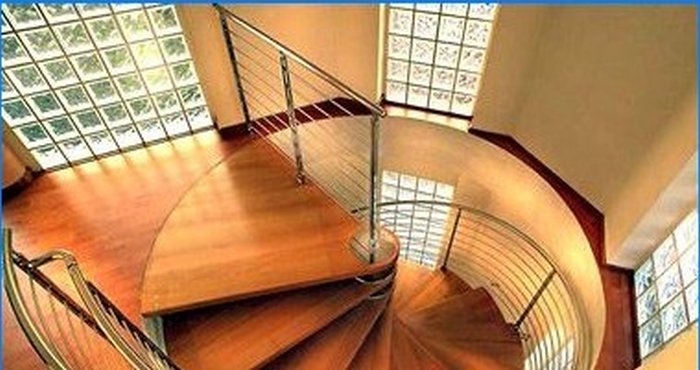

A spiral wooden staircase, consisting of only steps, takes up a small area, it can be created in any room – and it will decorate this room. The main inconvenience of a spiral staircase is movement in a spiral, with the need to carefully look at your feet and hold on to the railing, a quick descent / ascent along it is more dangerous than along stairs of other structures.

A wooden staircase can be a combination of several (two or more) types of staircase construction, for example, combine a marching and spiral flights, supported by stringers (or bowstrings) and a central pillar. The combined staircase will have advantages and disadvantages depending on the type of each flight in its design.

In general, wooden stairs have such positive qualities as strength and resistance to stress, harmony with the interior of the premises, relative cheapness and ease of use. Solid wood used in the construction of wooden stairs is environmentally friendly.

A common drawback that all types of wooden stairs have is that after several years of operation, ascent / descent along them is accompanied by a creak.

Manufacturing of wooden stairs – details

Not all wood is suitable for making stairs. For the main supporting elements of the stairs, hardwood is used – beech, maple and oak, because the wood of these trees is the least susceptible to drying out – the main reason for the squeak when walking on wooden stairs. Other elements of the staircase structure, including decorative ones, are made of cherry and hornbeam, walnut and ash, teak and rosewood. When calculating the construction of a staircase, it is necessary to take into account the physical properties of each type of wood, they are different and their incorrect use can cause a decrease in the strength of the entire staircase.

The table shows the density of some types of wood used to create stairs:

| Rosewood | Ash | Teak | Oak | Beech | Maple | Cherry | Nut | |

| density, kg / m3 (at 12% humidity) |

850 | 750 | 720 | 690 | 670 | 670 | 660 | 640 |

As a rule, a wooden staircase is not painted; it is varnished in several layers. The natural pattern of the wood will be preserved, therefore, the nature of the cut of the solid wood chosen as the material for the wooden staircase will matter. The tree trunk is sawn in two directions – radial and tangential.

The radial cut goes along the core of the tree trunk, the resulting solid has almost the same texture and color. An array of radial wood is the most resistant to any impact and deformation, it is wear-resistant, which means it is durable. However, the cost of such a cut is high, because only 10-15% of the finished product is obtained from the tree trunk, and the rest goes to waste.

With a cut, called a tangential cut, the cut is cut away from the core through the tree rings of the trunk. The texture of such an array is saturated with a pattern of tree rings in the form of waves. The array obtained in this way has lower quality indicators than the radial one, and it is cheap.

Connecting ladder parts

There are many ways to connect the wooden parts of the stairs; they need to be discussed separately. In short, amateurs use nails and screws, professionals use hidden groove and finger joints and special adhesives. The strength and appearance of the staircase will depend on how and what the details of the staircase will be connected with. Nails and screws are still used by some manufacturers, but such a connection gives an unattractive look to the structure, therefore, the heads of the nails (screws) must be sunk, gluing them on top with wooden plugs – if the stairs are painted with paint, the joints will not be visible. If the staircase is varnished, then the corks will not save – the joints will be visible. Therefore, it is important to avoid using screws and nails on visible parts of the stairs..

What are the different types of wooden stair structures and what are their unique characteristics?

There are several types of wooden stair structures, each with its own unique characteristics. The most common types include straight stairs, L-shaped stairs, U-shaped stairs, spiral stairs, and curved stairs.

Straight stairs are the simplest and most common type, running straight from one level to another. They are easy to construct, cost-effective, and practical for homes or buildings with limited space.

L-shaped stairs, also known as quarter-turn stairs, consist of two straight flights of stairs at a 90-degree angle. They are versatile and can be easily integrated into different architectural styles.

U-shaped stairs feature two parallel flights connected by a landing, forming a U-shape. They require more space and offer a grander appearance, often used in large homes or commercial buildings.

Spiral stairs, as the name suggests, are designed around a central pole, creating a spiral shape. They are compact and suitable for smaller spaces. However, they can be challenging to navigate for people with mobility issues.

Curved stairs are custom-made to fit specific spaces and have a smooth, flowing design. They create a sense of elegance and luxury, commonly found in high-end homes or grand staircase designs.

The unique characteristics of each wooden stair structure vary from aesthetics to functional aspects such as space requirements, mobility considerations, and architectural compatibility.

There are several types of wooden stair structures, each with its own unique characteristics.

1. Straight stairs: This is the most common and simplest staircase design. It ascends in a straight line, making it easy to construct and navigate. However, it requires a significant amount of space.

2. L-shaped stairs: These stairs turn at a right angle midway, forming an L-shape. They are more compact and suitable for limited spaces. L-shaped stairs can also provide a landing for a smooth transition between floors.

3. U-shaped stairs: These stairs resemble the letter U and consist of two flights that turn 180 degrees at a landing. U-shaped stairs are elegant and grand, but they require a significant amount of space.

4. Spiral stairs: These stairs revolve around a central pole, saving space and creating a visually appealing design. They are ideal for compact areas or for adding a unique architectural element to a space.

5. Curved stairs: These stairs offer a graceful curve instead of sharp angles. They are aesthetically pleasing and can be custom-built to fit any space, but they require meticulous craftsmanship.

6. Floating stairs: These stairs create an illusion of floating as they lack visible supports or risers. They provide a modern and open look but may require extra structural support.

Each type of wooden stair structure has its own advantages and considerations, and the choice depends on factors such as available space, desired aesthetics, and the overall design of the area.

There are several types of wooden stair structures, each with its own unique characteristics.

1. Straight stairs: These are the simplest and most common type of stairs. They are straight and have no turns or landings. They are easy to build and are suitable for small spaces.

2. L-shaped stairs: These stairs have a landing that changes the direction of the stairs at a right angle. They are more visually appealing than straight stairs and can be used in larger spaces.

3. U-shaped stairs: Similar to L-shaped stairs, U-shaped stairs have a landing that changes the direction of the stairs twice, forming a U shape. They are ideal for larger spaces and provide a grander appearance.

4. Spiral stairs: These stairs wind around a central pole or column in a spiral shape. They are space-saving and are often used in tight spaces or as a secondary staircase.

5. Curved stairs: These stairs feature a curved shape, adding an elegant and luxurious touch to a space. They are custom-built and can be more expensive than other types of stairs.

Each type of wooden stair structure has its own unique characteristics in terms of design, aesthetics, and functionality. Ultimately, the choice of stair structure will depend on the space available, the architectural style of the building, and personal preference.