Recommendation points

- Strengths and weaknesses of composite rebar

- Benefits in the context of the foundation

- Calculation of composite reinforcement

- Rules for working with material

- Knitting of spatial reinforcing structures

Competent builders understand how important it is to introduce new technologies and materials into their practice. The world has known about composite reinforcement for a long time, but its mass production and application took off only a few years ago. We will talk about the features of working with fiberglass reinforcement using the example of a foundation.

Strengths and weaknesses of composite rebar

Don’t expect any building material to be a unique and unified offering. However, the correct application in accordance with the operating conditions can achieve truly outstanding results. So it is with composite reinforcement: using its positive qualities and leveling negative ones, it is possible to ensure long-term operation at lower material costs..

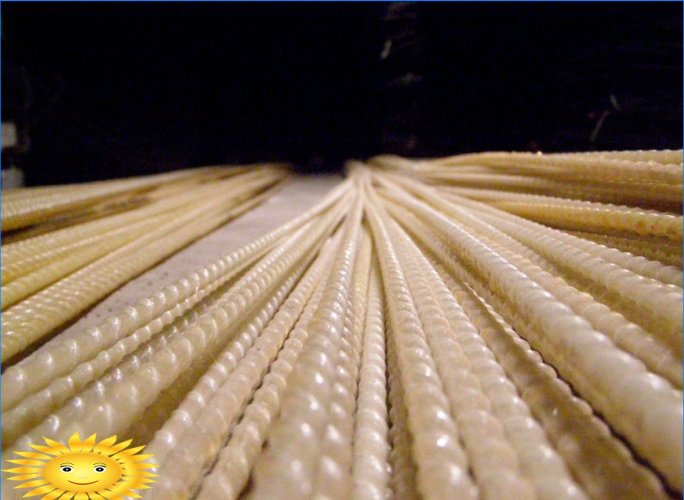

The main advantage of glass-polymer reinforcement is considered to be its inherent high limit of destructive effect – almost 2.5 times higher than that of steel. Composite reinforcement is much better at performing work to compensate for tensile forces in a concrete mass than steel. Especially when you consider that during production, plastic rods can be provided with a surface texture that contributes to the most effective adhesion to the concrete mass..

Another obvious plus is its extremely high resistance to aggressive environments. Concrete structures that are permanently in conditions of high moisture content or exposed to salt solutions, in the case of reinforcement with composite materials, have a much longer service life. We must not forget about the manifestations of electrolysis: the dielectric properties of plastic can be both a plus and a minus..

Not without a fly in the ointment: fiberglass reinforcement irreversibly loses its properties when heated. This forces us to reconsider the feasibility of its application from the point of view of fire safety. When heated to 150–200 ° С, the reinforcement loses its strength properties, if thermosetting polymers were used as a binder, the reinforcement loses its strength irreversibly.

Another disadvantage of composite reinforcement is its low modulus of elasticity, that is, low resistance to bending. Because of this, in structures with concentrated impacts, it is required to lay fiberglass reinforcement in quantities up to 4 times higher than the standard content for the section in comparison with steel reinforcement.

Benefits in the context of the foundation

The flexibility of polymer reinforcement allows its transportation in coils, thus the length of a single element is practically unlimited. Together with the low weight of the material (3-4 times less than that of steel), all other properties provide cheap delivery without the use of long vehicles, as well as high ease of use.

Foundations are not exposed to open flames and high temperatures in a fire, which is why low thermal resistance is not a significant disadvantage. The high flexibility of the reinforcement can only be of importance when working in structures with nodes of concentrated impacts, for example, when constructing grillages. However, it is possible to restore the resistance of concrete to bending loads by laying a relatively small amount of steel reinforcement, or simply by increasing the number of piles.

Much more important for foundations is the corrosion resistance of fiberglass. It is not so important for the subsequent hydrophobization and waterproofing of concrete, however, the susceptibility of strip foundations to rupture due to an increase in corrosive metal in volume can be disregarded in the case of using polymer reinforcement. Fiberglass is optimal for the construction of floating foundations in areas without drainage and with a high content of chemically active compounds in the upper water. Even under normal conditions, the use of fiberglass reinforcement makes it possible to reduce the protective layer of concrete to a minimum of 15–20 mm, thereby making it possible to move the reinforcement to the zone of maximum effective load absorption.

Calculation of composite reinforcement

If the methods for calculating steel reinforcement are well mastered by most builders, the design of foundations with fiberglass reinforcement is still considered an insufficiently covered topic. The reason for this is the different physical and mechanical properties of the reinforcement, which are not yet taken into account in most of the existing building codes. The simplest method for calculating composite reinforcement is the method of equal-strength replacement, in which steel rods are replaced by glass-reinforced plastic ones with a reduction in size by two values (that is, 8 mm instead of 12 mm or 14 mm instead of 18 mm). However, the calculation of complex foundations is recommended to be performed according to the general scheme from scratch, so as not to lose sight of the significant difference in the value of the elastic modulus.

The first part of the foundation calculation contains the determination of the effects on the base of the building and is carried out in the same way as for reinforced concrete structures. The second part begins with determining the sufficient cross-sectional dimensions of concrete structural elements and here you can see the first differences. Since the tensile strength of fiberglass reinforcement is higher, and the protective layer is minimal, the sufficient cross-sectional area is 25–30% lower than the standard minimum for a reinforced concrete product with an equal cross-section of the reinforcing elements. This does not apply to the determination of the width of the bottom plane of the foundation, which is always determined from the actual loads and the supporting capacity of the soil. Therefore, when reinforcing with composite reinforcement, it is beneficial to pay attention to the foundations of complex sections..

The next stage is the choice of an equivalent replacement for steel reinforcement, which consists in preserving not only strength, but also all other physical and mechanical properties. The main nuance is that fiberglass reinforcement undergoes 3-4 times greater linear elongation before it ceases to resist the destructive effect. This means that the total cross-section of the reinforcing elements in the tensile loading zone must be correspondingly higher than when using steel reinforcement. The benefit from the use of fiberglass reinforcement in this case is expressed only by high tolerances for the opening of cracks – for polymer reinforcement, contact with air or moisture is not critical, but the effect of frost forces on concrete should not be overlooked. The general trend is as follows: the results of savings on the volume of concrete mix should be directed to strengthening the composite reinforcement in the designated areas.

Rules for working with material

Differences in working with polymer reinforcement lie not only in the calculation method, but also in the methods of material processing. In particular:

- Cutting fiberglass reinforcement should be done with either a hot torch or a bolt cutter. Sawing polymer reinforcement by any means leads to the formation of harmful microscopic chips.

- Bending of reinforcement is allowed only when manufacturing structural reinforcement elements. It is performed by heating the bent section to 100-120 ° C using an electric hair dryer, followed by natural cooling after the product has taken the required shape.

- When storing composite reinforcement, protect it from direct sunlight and high temperatures..

- When unwinding the reinforcement, its high elasticity should be taken into account. To relieve stress in the turns, the end of the armature should be temporarily fixed to the coil body with a meter-long chain. If the coil is supplied without a coil, 2-3 wire rings must be attached to the coil before cutting the clips to prevent slipping of the rods..

Knitting of spatial reinforcing structures

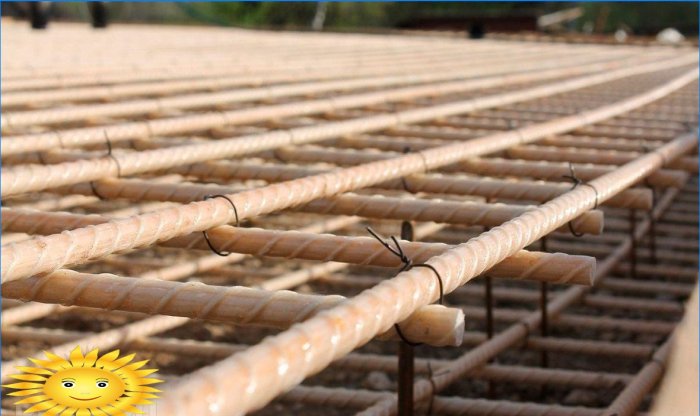

The process of assembling a frame made of glass-polymer reinforcement is drastically different from metal knitting. The root of most of the differences is the practically unlimited length of the rods: a parallel bundle of rods is rarely used. Because of this, the frame for the entire product is much more convenient to knit in place, and then unload it into the formwork. This is also facilitated by the low weight and resistance to corrosion: for the safety of fiberglass reinforcement, it is enough just to cover it from sunlight..

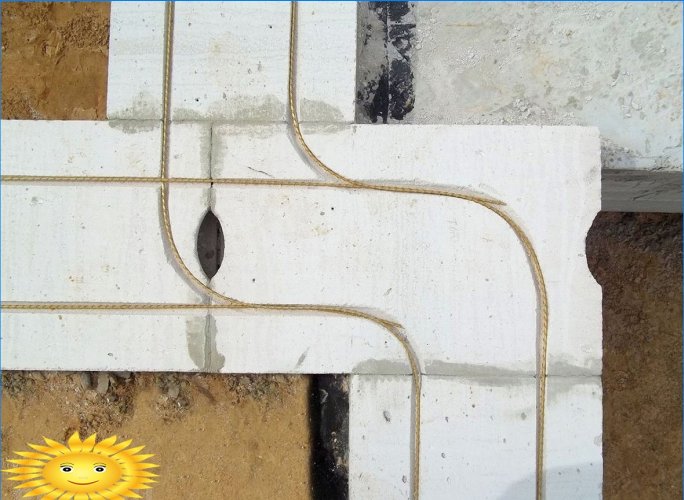

The preparation of frame parts, as in the case of steel rods, should be done before assembly, that is, all work is carried out mainly by the manufacturing method. The data of the rows at the corners and junctions should be performed with viscous crosshairs, and if necessary, increase the molding by parallel binding with an overlap of at least 20 diameters. The crosshairs are knitted by braiding each of the perpendicular rods with a ring, which pulls the reinforcement together. For parallel tying, 3-5 straps are installed in 2 turns. You can use for this purpose both nylon ties and PET tape with its subsequent heat shrinkage..

If it is necessary to include complex-shaped anchors into the reinforcement, they are bent from metal, or factory bent products are used in those joints of the structure where fiberglass reinforcement can do its job. In this case, it is necessary to increase the thickness of the protective layer at the installation site of the steel elements, and to perform a bunch of dissimilar materials with polymer wire.

What are the advantages of using composite fiberglass reinforcement for the foundation compared to traditional reinforcement materials like steel?

How does using composite fiberglass reinforcement for the foundation impact the overall durability and longevity of the structure?

Why would someone choose to use composite fiberglass reinforcement for the foundation instead of traditional steel reinforcement? Are there any specific advantages or disadvantages associated with using this material in terms of durability, cost, or installation process?