Recommendation points

- The choice of corrugated board for the fence

- Installation of screw piles

- Calculation and design of the supporting frame

- Fence cladding and rules for working with material

Profiled sheet for a fence is used quite often: the material is inexpensive, versatile and very easy to use. And on screw piles, a fence can be built in a matter of days. Naturally, if you know the technique and specifics of installation, which we will discuss in this article.

The choice of corrugated board for the fence

In order to save money for the fence, professional sheets with the least relief are purchased. It makes no sense to buy material with a wave height of more than 20 mm, although the assortment of most manufacturers includes sheets with a wave of up to 35 mm. The corrugated board for the fence is marked C-XX, the extreme waves on both sides of the sheet are sunken, there is no hydraulic lock.

The coating of the sheets can be different, ranging from ordinary hot-dip galvanizing to a thick layer of polymer with a texture. The most inexpensive options are suitable for technical and temporary fences. For stationary fences, sheets with monochrome coloring or a print of natural materials are better suited, and colored polyester coatings are the most durable.

At your request, when ordering the material, one or both edges of the corrugated board can be cut in the form of a semicircular ridge or arch, it is possible to perform a rounding with a width of several sheets. If high strength of fences is required, it is reasonable to pay attention to sheets with a thickness of more than 1 mm with high relief, or stamped stiffeners.

Installation of screw piles

They use corrugated board for fences of various types, including columnar or with a strip foundation-mur. However, pre-fabricated fences on screw piles are becoming more and more popular. Although this option is slightly more expensive than concreted poles, there are clear benefits from simple installation and high operational loads. On the other hand, on unstable soils, screw piles remain the only way to arrange a reliable supporting frame, and in the case of temporary fences, such supports can be used many times.

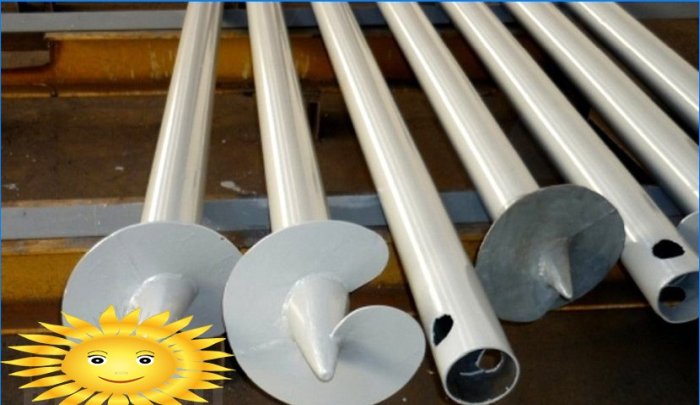

For fences made of corrugated board, welded SVSN piles up to 5 meters long without a top are used. The diameter of the pile pipe with a span length of up to 2 meters is chosen 57 mm, and for spans from 2 to 3 m – 76 mm. The piles are screwed in to such a depth that the screw is located below the depth of soil freezing. In some cases, a layer of soil with sufficient bearing capacity is located deeper and this feature can only be identified by geological surveys.

Installation of screw piles does not necessarily require the involvement of special equipment, although it is preferable. Self-deepening of the pile requires at least three people, one of whom supports the pile and monitors compliance with the vertical level. Two other people, holding the levers of a special key, exert axial pressure on the pile and turn it clockwise, slowly immersing the support into the ground. After installation, the inner cavity of the pile can be filled with concrete with a fraction of the main filler up to 5 mm, otherwise it is required to plug the hole with a plastic plug.

Installation of piles under the fence begins from key points – corners and turns, between which there are even spans of the fence. These piles need careful control of the vertical level and adjustment of the immersion depth with a tolerance of 3-5 cm.

Further marking is carried out from the extreme piles of the span, between which a nylon thread is pulled from the outside, 20 cm from the upper end and 50 cm from the ground. The span is divided into equal intervals up to 3 meters long and the places for the installation of intermediate supports are marked. The piles are screwed in exactly along the thread, you only need to control the vertical level in the plane of the fence.

Calculation and design of the supporting frame

A fence made of corrugated board is characterized by high windage and requires a serious approach in organizing the supporting frame. To partially compensate for the wind load and to avoid contamination of the lower part of the fence with mud splashes, the sheets are placed at a height of 20-25 cm from the ground. This space is closed with a fine mesh stretched in a corner frame 20 mm wide. To give strength, the frame is connected to the lower crossbar by vertical posts in 2-3 places per one span.

Horizontal beams are made of steel angle or square tube, the width of the guide should be at least 50 mm. With a leaf height of up to 1.5 meters, two horizontal bars are sufficient, located 30–40 cm from the top and bottom edges. A higher fence requires additional jumpers so that the clearance does not exceed one meter. This is not so much a requirement for structural strength as a way to get rid of hum and vibration. For this reason, additional crossbars can be made of a material of lesser thickness, for example, from a corner with a shelf of 25 mm or a square pipe 20×20 mm.

The main bearing rails are welded to the piles from the outside. Additional crossbeams are attached to the piles through pads of the required thickness so that their outer edge comes out on a common plane with the main ones. If the span is more than 2 meters long, it is necessary to connect the crossbars using vertical or inclined jumpers at least in one place in the middle of the span. The crossbeams can be built up by connecting pipes or corners end-to-end and welding the seam along the entire length, followed by its cleaning.

It is also possible to connect the elements of the supporting frame using bolts. For reliable fastening of the crossbars to the round profile pile, special brackets are used. In this case, the “light” assembly is performed first, and only when the structure is fully assembled, the joints are tightened completely. This option is especially popular for the construction of temporary fences..

Fence cladding and rules for working with material

Before fastening the sheets, a nylon cord is pulled horizontally over the span, along which the upper edge will be aligned. To prevent the cord from clinging to the installed sheets, it is raised higher by a fixed distance, which is taken into account during further installation.

To fasten the corrugated board to steel beams, roofing screws with a drill and a hexagonal head are used. Sheathed the fence, starting from the corner. The extreme sheets of two spans are compared without trimming with the smallest possible gap, while both of them should be set strictly vertically. The corner is subsequently covered with a rectangular roof ridge.

Each new sheet is matched in height with the previous one, making an overlap in one wave, then pre-fastened with one self-tapping screw to the upper guide. Even when laying sheets in a wave, their inclination can be adjusted in the range of 1–1.5 mm. When the sheet is aligned, it must be secured with a second self-tapping screw to the upper crossbar. The corrugated board is attached to the frame through one wave, be sure to stitch both sheets on the overlap. If the head of the self-tapping screw breaks off, the rod needs to be pushed into the depth with a punch and a new screw must be screwed into the same hole.

If the fence has a turn with an angle of up to 25 °, it can be bypassed without cutting, you just need to bend the sheet to the guides and gradually press it with self-tapping screws, starting from the corner. The sheets are usually cut at the end of the span, the cut is covered with bitumen mastic.

Can you please provide more information on the durability and stability of a DIY fence made of corrugated board on screw piles? How well does it withstand harsh weather conditions and potential maintenance issues? Any tips or considerations for someone planning to build such a fence? Thanks in advance!