Recommendation points

- What is the difference between granite and ceramic tiles

- Why in many cases tile gives way to granite

- In which room can granite be laid on the floor

- How to choose granite for your floor

- What affects the price of granite tiles

Want to learn how to work with granite, but have little practice or knowledge? In this article, we will consider the properties of granite that need to be considered when choosing a material, and how to install it. We will study the stages of making a granite floor, revealing all the secrets and subtleties of work.

What is the difference between granite and ceramic tiles

Many rooms in a house, apartment, industrial use require special attention when choosing a floor covering. Since not only the beauty of the interior plays an important role in the choice of material, but also wear resistance, durability and ease of maintenance. These materials include natural stone, while the tile loses in many respects.

Why in many cases tile gives way to granite

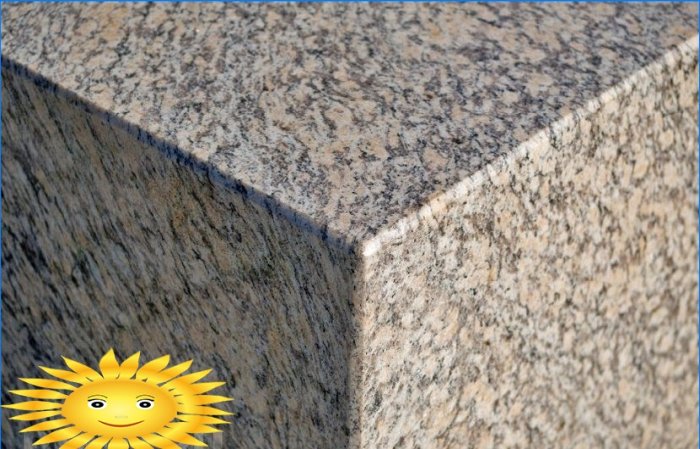

It is worth listing the properties of granite, such as high strength of the stone, resistance to abrasion, granite does not lose its appearance under the influence of time, water, sun, tolerates temperature fluctuations, is easy to clean. And ceramic tiles have a shorter service life, as they are more prone to scratches and even cracks. Also, the strength of the adhesive on which it was glued to the floor is often compromised. Therefore, if you set yourself the task of finding the best material for the floor, then granite is what comes first..

In which room can granite be laid on the floor

The area of application of granite is extensive. This can be a floor in a kitchen, bathroom or living room, a floor in a veranda or porch, a floor in a garage, pool or garden gazebo. You could often find granite in expensive shopping malls and in the subway.

Besides strength and durability, there are other differences between ceramic and granite tiles. And sometimes it is the ignorance of these differences that leads to mistakes in working with the stone. When making a granite floor, you need to take into account some of the fundamental differences between natural stone and ceramic tiles:

| Granite | Ceramic tile | |

| Price | From 35 to 200 $ per 1 m2 note: masonry consumables and tools are more expensive than ceramic tiles |

From 8 to 60 $ for 1 m2 |

| Weight | 20 mm thick tiles weigh about 53 kg 1 m2, a 30 mm – 83 kg 1 m2 note: 10mm tiles are not suitable for floors |

Ceramic tiles weigh about 15 kg 1 m2 |

| Manufacturing | A natural stone. Color, pattern and grain may vary note: even if all tiles are made of the same granite slab, there is a chance that some elements will be quite different from others. In small quantities it is worth ordering several more tiles. And when ordering large volumes, the material is cut from different slabs. Even if the deposit and the name of the granite are the same, the color of the tiles can be very different |

Artificial cladding material made by different methods: casting, cutting, extrusion or pressing. Often contains natural components, but still inferior in naturalness to granite |

| The size | Granite tiles can be of different lengths, widths and thicknesses. The first cut can be 3 mm thicker than the next cut. This must be taken into account during installation. | High quality ceramic tiles are perfectly sized. There is practically no marriage in size. Thanks to this, it fits without any difficulties. |

| Colour | Small selection of natural colors and shades | A huge selection of colors, shades and patterns is a strong argument for ceramic tiles. You can choose for every taste, taking into account the requirements of the interior |

| Life time | Almost unlimited service life. The possibility of repeated laying and restoration will allow granite tiles to stand for several centuries, about 500 years | About 60 years old |

| Abrasion | The abrasion of granite tiles is negligible, about 0.10 mm per year, provided that 1 million people walk on the floor per year | Abrasion of ceramic tiles from 0.15 to 0.40 mm per year, provided that 1 million people walk on the floor per year |

| Strength and load carrying capacity | 552.7-604.6 kg / cm2 | 280-435 kg / cm2 |

How to choose granite for your floor

Most often, the difference between natural stone and ceramic tiles complicates the work. Since the naturalness of the material entails errors in the tiles themselves, which must be taken into account when laying.

Granite is a rock that is mined several kilometers underground, most often with explosives, although more modern mining methods exist. The mined stone looks like huge fragments. Huge rectangular blocks are cut from these fragments, which are then cut into granite slabs. They have a size: length about 1.5 m, width from 0.35 to 1.25 m, thickness 20-40 mm. It is these granite slabs that you will find at exhibitions in stores where you can choose granite.

Natural stones such as labradorite and gabbro are often mistakenly called granite. They are very similar in properties and appearance. Labradorite has a coarse-grained structure and a beautiful play of colors. But due to the fact that certain minerals are present in the stone, it does not tolerate the environment well. Therefore, labradorite is not used for outdoor work. Gabbro differs from labradorite and granite in color. It has a deep black color and a polished surface, which is why it is often used in interiors. In addition, gabbro is used for the manufacture of monuments.

When buying granite, be sure to pay attention to the following points:

- The color depends on the stone deposit: in each quarry, granite has its own natural color.

- Granite tiles are cut to order in the granite workshop. The most popular sizes are 300×600 mm or 600×600 mm, with a thickness of 20-30 mm. It is necessary to understand that the larger the tile size, the more beautiful the floor will look. But it will be very difficult to lay large tiles. Firstly, it is heavy, it can break in half under its own weight. Secondly, it is more difficult to maintain the level. The thickness of the granite tiles depends on the room and floor loads. It is impossible to cut slabs into tiles on your own; this requires very large and expensive professional machines. An exception may be cases when you need whole slabs for the floor, for example, for the floor in a wine cellar.

- Type of stone processing. Floor tiles can be:

- polished – the slabs have a mirror surface on which the entire pattern of the stone is visible. This species is the most beautiful, but also the most slippery. And yet, although granite is a solid stone, it can still be scratched. Scratches are more visible on polished tiles.

- heat-treated – the tile is treated with a high-temperature gas jet, after which it becomes rough and does not shine, more suitable for steps and floors on a veranda or porch, as it will not slip in winter.

- polished – the slabs, just like the polished ones, have a surface on which the natural pattern of granite is visible, but they absolutely do not shine.

There are also sawn and bush hammered granite tiles, but they are not suitable for floors..

What affects the price of granite tiles

All of the above parameters affect the formation of value. When choosing a certain type of stone, ask about its availability in the warehouse in the required quantity and its deposit, the more rare the material and the further away its place of extraction (taking into account transportation), the more expensive it will be. The size of the tile itself (its width and length) does not really affect the price, since you pay for the area of the granite slabs themselves, and not for the number of products. Price for 1 m2 slab depends on its area, and especially on the thickness. The thicker the future tile, the more expensive it will be.

The price varies from 35 to 200 $ per 1 m2. Naturally, you can find prices of $ 400 and $ 500. At the same time, sellers can deceive that this is a very expensive Italian granite, of a rare exclusive color. And you, as a beginner, will not even notice that it is Russian or Ukrainian granite. Be careful not to pay two prices. As for the type of processing, polished tiles are often more expensive than heat-treated ones..

Thus, it can be concluded that granite tiles are better suited for floors than ceramic tiles. Due to its properties, it will last a long time and withstand quite strong loads. The existing difficulties in working with granite due to color, size and weight must be taken into account during laying, then the expended efforts and material costs will bring a positive result. The main thing is to understand the features of granite tiles and working with them.

How difficult is it to install granite flooring by yourself?

Installing granite flooring by yourself can be quite challenging and requires careful preparation and some level of expertise. Granite is a heavy and hard stone, making it hard to handle and cut. Additionally, precise measuring and cutting is necessary to ensure proper fitting and alignment of the tiles. The installation process involves several steps, including subfloor preparation, applying adhesive, laying the tiles, and grouting. Without the right tools, knowledge, and experience, it can be time-consuming and prone to errors. Hiring a professional installer is often advisable to ensure a proper and professional finish.

Can anyone share their experience or tips on installing granite flooring by themselves? I’m curious about the process and the possible challenges one might face. Any advice on tools, materials, or techniques would be greatly appreciated!