Recommendation points

- What is the plate made of and how is it made

- Scope of GSP

- Advantages of gypsum board

- Drywall problems

Due to its excellent performance, gypsum particle board or GSP, despite its novelty in the domestic market, has already found wide application in construction. Let’s take a closer look at the advantages and disadvantages of this material, its quality characteristics and application features..

What is the plate made of and how is it made

Gypsum boards consist of a small number of components: they are made from gypsum and wood chips with the addition of water. Gypsum as a percentage in the slab is 83%, and another 15% is shavings, the rest is moisture. It is noteworthy that for the manufacture of GSP, not waste is used at all, but full-fledged, prepared wood material, previously cleaned of bark and impurities.

The technological process for the production of boards consists in crushing wood and saturating it with water. At the same time, gypsum is crushed and dried. The resulting mixture is molded and sent to the press, after which the slabs undergo an additional stage of drying and cut to size.

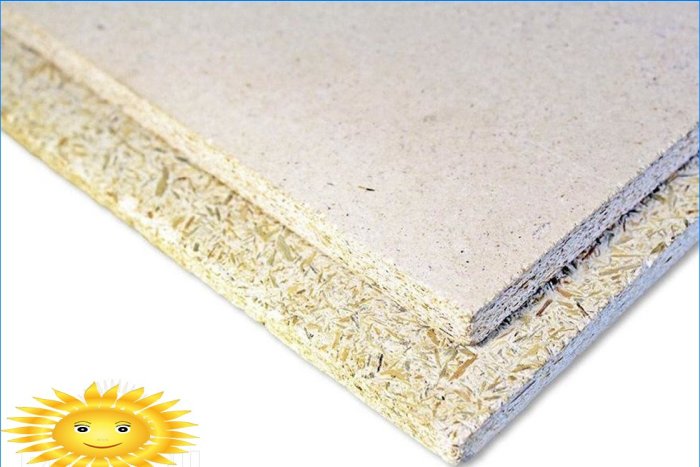

In fact, GSP is a gypsum board uniformly reinforced with a wood component. The front side of such boards has a flat and smooth surface, the reverse side is somewhat rough, and in its texture it is clearly possible to distinguish chip material.

Scope of GSP

The main purpose of the slab is the arrangement of interior cladding of premises in residential buildings and at social facilities – in hospitals, schools, kindergartens, as well as in industrial buildings..

Thanks to its perfectly flat geometry, the gypsum board is perfect for finishing work. GSP is actively used for interior decoration in the construction of frame houses, in the installation of prefabricated bases.

One of the most demanded areas of using GSP is the installation of partitions for dividing the space inside the premises. Such partitions are fixed on a frame made of wood or metal. The material is especially popular in the segment of flooring. In particular, GSP is used for laying sub-floors. Moisture-resistant tongue-and-groove boards (GSPV) are laid on a dry screed (usually fine expanded clay). If we are talking about installing floors on logs, then in this case, two sheets of GSP are used, laid with an overlap.

Recently, craftsmen are increasingly using gypsum particle boards for arranging ceiling structures using lathing made of steel rails or wooden beams. Such ceilings level the surface well and provide additional sound insulation. GSP is also used for cladding roofs and walls on the upper levels of the house – to create additional rooms (attics) in the attic areas.

Advantages of gypsum board

Gypsum board is the most comfortable to install and use, extremely safe building material, easily amenable to any kind of processing, and, as mentioned above, quite accurate geometrically.

Among other things, the material is suitable for use in both dry and damp rooms. The excellent qualities of GSP are determined by a number of its characteristics, including in terms of fire safety, environmental friendliness, strength, indicators of resistance to unfavorable biological factors.

Let’s consider in more detail the qualitative indicators of GSP:

1. High environmental friendliness.Since formaldehyde resins, as well as volatile and toxic compounds (unlike, for example, chipboard or OSB), are not used in the production of GSP, such material does not evaporate into the environment substances that negatively affect human health. It is for this reason that SHGs are used in social and childcare institutions..

2. Fire safety.Due to the fact that gypsum accounts for the lion’s share in the chemical composition of GSP, such slabs are classified as low-combustible building materials. Due to their high fire safety, manufacturers recommend gypsum boards for installation not only in private residential buildings, but also in the construction of staircases, elevator halls and lobbies of multi-storey buildings.

3. Biological safety.GSP is one of the few materials with a high wood content that is not affected by fungi and microorganisms that adversely affect organic products. In addition, not only insects, but also rodents are not afraid of covering from a gypsum board – such material is unattractive to them..

4. Indicators of strength.Since the gypsum base in GSP is reinforced with wood components, this material is considered strong enough, it is designed for heavy weight loads. The level of bending strength of the slab is, depending on the product modification, in the range from 8 to 15 MPa.

5. Resistance to moisture.The degree of resistance to the influence of moisture for gypsum boards varies depending on the specific modification of the GSP. In particular, ordinary (“dry”) slabs are not recommended to be mounted in those rooms where a high concentration of moisture is stable..

In the event that moisture is exposed to HSP intended for dry rooms, the swelling rate of the material will be 2% with a low level of linear expansion, and water absorption will reach 30%.

In this regard, GSP compares favorably with chipboard and OSB – the latter can not only be strongly deformed, but also quickly collapse under the influence of water. As for the moisture-resistant modifications of gypsum board (GSPV), they can be safely installed in bathrooms – the material does not swell at all, and the level of water absorption barely reaches 10%.

6. Soundproofing qualities.The reason for the private use of GSP as a material for arranging walls and partitions is the good sound insulation performance of the slab. Without taking into account the additional sound damping due to the external material of the walls and insulation, the level of noise suppression of the GSP alone is in the range from 28 to 35 decibels.

For comparison, a wall layer of one brick reduces the sound pressure by only six decibels. Good insulation of premises from external noise with the help of GSP became possible due to the excellent sound-absorbing properties of the main component of the slab – gypsum.

7. Ease of finishing.An important factor for a builder or craftsman when arranging finishing is the ease of working with the surface. In the case of GSP, a pleasant surprise awaits you – such boards are characterized by an absolutely flat plane with good adhesion, which allows you to easily glue not only wallpaper, but also ceramic tiles, laminate, and linoleum onto the board. For cutting and other types of GSP processing (grinding, milling or drilling), it is enough to have tools designed for working with wood materials.

Drywall problems

Unfortunately, ideal building materials do not exist, and gypsum board is no exception in this regard. Despite a number of obvious advantages, GSP has obvious disadvantages.

First of all, it is its great weight. The most common range of gypsum board thickness on the domestic market at the present time is 10 and 12 millimeters. At the same time, the material from which the slab is made has a rather high density – within 1.25 tons per cubic meter. Thus, a GSP with a thickness of 12 millimeters with dimensions of 3×1.25 meters weighs within 56 kilograms.

Remember:a structure of such a weight is quite problematic to mount independently. This also imposes certain restrictions on the dimensions of the slab if it is installed on the ceiling..

In addition, due to the high content of gypsum, the processing of this material, if it cannot be characterized as complex, can deservedly be called problematic. In particular, many craftsmen are well aware of how difficult it can be to accurately drill or cut plaster..

In addition, during the processing of GSP, a large amount of dust is formed, which requires the mandatory use of a respirator or other respiratory protection, and does not have the best effect on the efficiency and overall comfort of work..

However, despite some inconveniences in working with gypsum boards, if we compare them with other wood-based panel products that are now on sale, then in terms of quality characteristics, indicators of wear resistance, safety and strength, GSP is perhaps the best building material in this segment.

Despite the fact that in European countries such plates have been used since the eighties of the twentieth century, in Russia they became known only in the last decade, however, even in such a short period of time, GSP has confidently won its niche in the construction market.

I am not familiar with GSP as a material. Could you please provide more information about GSP? Is it a specific type of gypsum board or a different material altogether?

I’m not sure if “GSP” is a typo or an abbreviation but if you’re referring to gypsum board, it is typically made of a layer of gypsum plaster sandwiched between two layers of paper. However, if “GSP” is something else, could you please clarify what it stands for?