Recommendation points

- How to choose the best laminate flooring

- How the laminate works

- The main characteristics of the laminate

- Meaning of laminate markings

- What does laminate classification mean and how is it determined

- Two types of laminate panel joints

- The main mistake when laying laminate

- Laminate quality guarantee

- Laminate price

- Which laminate to choose

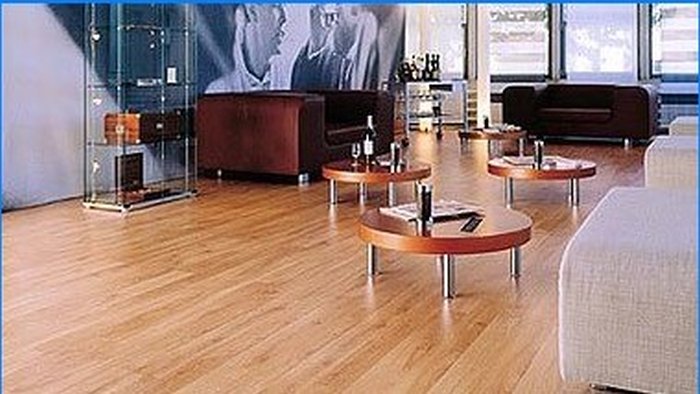

How to choose the best laminate flooring

Unlike a ceiling, flooring is one of the main concerns for a homeowner. Everything is simple here – the ceiling finish is exposed to much less stress than the floor. The flooring takes the stress of furniture, it is walked on, which means it is abraded and scratched. Undoubtedly, parquet will be the best floor covering, however, it is quite expensive and requires serious maintenance. An alternative solution here would be laminate – the lower price, rich colors, high-quality imitation of parquet flooring make it quite a worthy substitute for parquet. In addition, the laminate has many positive qualities inherent in parquet flooring..

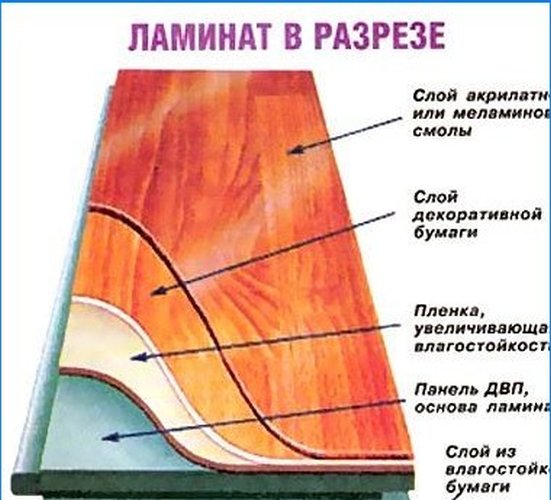

How the laminate works

Laminate of 31-33 classes consists of five layers: the upper (front) layer of malamine or acrylate resin, underneath is a decorative paper layer, below is a moisture-resistant film, the fourth layer is an HDF panel (laminate base) and the last, fifth layer is moisture resistant paper. Less quality laminate for residential use (class 21-23) consists of only 3 layers.

The designation HDF is translated from English as “high density wood board” – this material is much stronger than the widely known MDF or fiberboard panels, since it is produced under higher pressure.

The highest quality is considered to be a laminate, in which the layers in relation to the central base layer are mirror-like, i.e. the bottom layer, like the top, is made of synthetic resin. The difference between the front layer and the bottom layer is that the bottom layer has no decorative pattern..

The main characteristics of the laminate

Laminate flooring, as a rule, imitates the externally texture of various types of wood, however, there are brands of laminate with a pattern that has departed from the classic parquet canons – granite, marble, tiles, carpets, abstract paintings.

The laminate flooring consists of rectangular panels, 1000×2000 mm in size, consisting in turn of rectangular segments 1000 mm long and 200 mm wide or squares with a side of 380 mm (there are also squares with a side of 190 mm). Laminate thickness from 6 to 12 mm.

Unlike parquet flooring, laminate flooring does not require any special maintenance – it does not need polishing and scraping to clean its surface, just a regular wet cleaning. The legs and wheels of the home furniture do not cause any harm to the laminate. The laminate flooring is water-resistant and environmentally friendly, it is warm enough. It is difficult to get dirty – even random drops of varnish or paint can be easily removed with a cloth dipped in acetone. It is resistant to high temperatures – the proximity of heating devices, an accidentally dropped cigarette butt will not damage it.

The main disadvantage of laminate flooring is unprotected edges. They do not have a synthetic resin coating, which means they are more fragile and susceptible to moisture. The slightest disruption to the technological process in the production of laminate will lead to rapid damage to the edges, so it will be correct to choose a laminate from well-known, well-established manufacturers..

Meaning of laminate markings

Each package of one or another laminate is marked with a picture indicating the class of this laminate coating. The meaning of this marking is as follows:

|

The 22nd class of laminate is designed for use in residential areas – children’s and living rooms. Maximum service life – 4 years; |

|

The 23rd class of laminate flooring is also designed only for living quarters, but with a greater load on the floor surface – hallways, kitchens. Its service life is no more than 4 years; |

|

From the 31st class begins the laminate intended for commercial objects – it is much better than the coating produced for residential premises. Its service life as an office covering will be up to 3 years, but if it is laid in a residential building, then its service life will be much longer – up to 12 years; |

|

32-grade commercial laminate is intended for use in moderately stressed areas such as classrooms and reception areas. Under these conditions, it will last up to 5 years. If such a laminate is laid in a residential building, its service life will be up to 15 years; |

|

The maximum – 33rd – class of commercial laminate is intended for high-traffic areas – shops and restaurants. He will serve in these premises for up to 6 years. This is the best laminate for residential premises – its service life will be at least 20 years.. |

In addition to the class designation, there may be additional designations on the laminate packaging:

| Anti-static (does not attract dust); | |

| It does not require special care | |

| High resistance to various mechanical damage | |

| Not flammable | |

| A lit cigarette won’t hurt him | |

| Hygienic | |

| Does not fade under the influence of ultraviolet radiation | |

| Household cleaning products will not harm him | |

| Low wear resistance, chairs should be equipped with soft rollers | |

| Can be used as a covering on a warm floor |

Today, the minimum class of laminate is 21st, the maximum is 33rd. Some manufacturers indicate class 34 on packages – this class does not exist!

What does laminate classification mean and how is it determined

The two-digit class of laminate flooring denotes its durability – in other words, how long the laminate flooring will last before it is frayed. To test the laminate for wear resistance, it is subjected to the “Taber test”: a switched-on grinder is placed on it and grinded with an abrasive wheel until damage appears. During the test, it calculates the number of revolutions made by the abrasive wheel and determines the class of this laminate: 7000-11000 revolutions correspond to the 21-22 class, 11000-15000 characterize the 23-31st class, 15000-20000 revolutions of the abrasive wheel correspond to 32-33- class of laminated flooring.

Why is this method used to determine the durability of a laminate? The fact is that the main reason for the wear of the laminate flooring is walking on it. Accordingly, the more and more often people walk on the laminated flooring, the faster it will wear off. During the “Taber-test” the role of shoe soles abrading the laminate is performed by a grinder. This test method of laminate is carried out according to the European standard EN 13329 (there is no Russian GOST for laminate), and the laminate is classified according to the European standard EN 685.

Two types of laminate panel joints

In any case, the laminate is laid using the “floating floor” method – its panels are connected only to each other and are not attached to the base. There are two types of laminate, distinguished by the way these panels are connected to each other – adhesive (tongue / groove connection) and interlocking, better known as quick step laminate..

Laminate panels intended for adhesive bonding are fastened together at the ends – using a special, fast-drying adhesive. Such a laminate can only be laid by professionals. special skills and tools are required here – in particular, special straps for fastening panels. The very process of laying the adhesive laminate is long and difficult. It costs less than quick step laminate flooring, but is more expensive to work with as a result. hiring professional performers required.

The advantage of the adhesive laminate is that the surface formed by it from wall to wall is solid, has no cracks and gaps, i.e. its edges are much less vulnerable to moisture than a snap-joint laminate. The main disadvantage (in addition to the complex installation process) is the complete impossibility of repair – if one of the elements of the laid adhesive laminate is damaged, it cannot be removed and replaced without damaging the entire coating.

The lock (glueless) laminate, in turn, is divided into two types – click (collapsible locks) and lock (latches). The locks of the first type are double, located at an angle of 45 °, laying the laminate with such a connecting lock is easier to perform, because this work does not require special skills. In addition, click-lock laminate panels allow for some curvature of the base on which they will be laid (up to 3 mm drop per linear meter). Laying panels with lock locks requires a perfectly level base. If you intend to lay the lock laminate yourself, it is better to opt for a click-lock – it costs more than a lock-lock laminate, but does not require professional skills.

Unlike adhesive laminate, interlocking laminate can be repaired – if one panel is damaged, it can be replaced by disassembling part of the laminate. In theory, it is possible to dismantle / install the cover from the lock laminate up to six times (as some manufacturers say), in fact, the lock may not succumb to attempts to disassemble it – here you need to exercise maximum care so as not to damage the panels.

The disadvantage of a laminate with a castle joint is the susceptibility of its joints to moisture – as operation progresses, the gaps in such a floor covering begin to expand more and more, because after each wet cleaning, moisture penetrates into them, which makes the edges swell and “push” the plates, then dry, exposing the cracks. This process significantly shortens the life of the interlocking laminate, so some manufacturers recommend using glue or mastic to join..

Of great importance when laying the interlocking laminate is the horizontalness of the base on which it will be laid. The ideal base should have a difference of no more than 1 mm per two linear meters!

The main mistake when laying laminate

It consists in ignoring the underlayment – a special material designed to isolate laminate panels from the subfloor. In addition, the laminate underlay provides thermal insulation and sound insulation from walking noise, protects the laminate panels from moisture.

Laminate from some manufacturers is already equipped with a backing securely attached to each panel – but only some types of laminate, class 32 or higher, are equipped with it. Of course, the cost of such a laminate is quite high – at least 800 rubles / m2.

There are several types of underlay for laminate flooring:

- polyethylene foam backing, subdivided into foamed (polyethylene foam is chemically crosslinked or filled with gas) and physically crosslinked (using a reagent);

- cork backing. There are three main types: pressed (made from natural cork chips), rubber-cork and bitumen-cork;

- special backing.

The most popular underlay for laminate is made of polyethylene foam – it is cheap, has excellent moisture resistance, fungi and bacteria will not infect it, insects and rodents will not start in it. Foam laminate flooring is easy to work with and low waste. However, a substrate of this type does not hold its shape well and, as it is used, begins to sag in places, disrupting the horizontality of the entire laminate coating. In addition, the sun’s rays (ultraviolet light) seriously damage the foam backing..

Cork laminate backing is an excellent base for floating laminate flooring. Good heat insulator, not subject to mold and decay. The only drawback is that condensation may accumulate on the back of laminate panels laid on a cork backing.

Bitumen-cork and rubber-cork substrates do not have this flaw. The first consists of kraft paper impregnated with bitumen, coated on both sides with a layer of cork chips. The second is a mixture of pressed rubber and cork. Both of them are superior to the cork substrate in their qualities, they are well cushioned and do not wear down during the operation of the laminate coating..

The special underlays are of the best quality and effectively reduce any noise normally occurring during walking. The natural ventilation created in them prevents the formation of condensation, and laying the laminate on such a base itself takes half the time. However, with all the positive characteristics, such substrates have only one drawback – they are too expensive..

Common to all types of substrates is that they come in sheets and rolls. They smooth the main floor surface, creating the horizontal plane necessary for the laminate flooring.

Laminate quality guarantee

Manufacturers provide a guarantee for the laminate for a period of 5 to 15 years. As mentioned above, there is no Russian GOST for laminate flooring, imported laminate is certified for steel profile GOST 4598-86 (Fiber boards. Specifications). Russian-made laminate is produced according to the specifications of each manufacturer. Each batch of laminate must have a hygiene certificate.

Laminate price

Adhesive laminate flooring is currently underrepresented on the market due to its low popularity. The cost of the 21-23 grades of adhesive laminate is 420 rubles on average. / m2., 31-33rd grades – on average 470-520 rubles / m2.

Laminate flooring with a lock-lock: class 21-23 – from 450 rubles / m2, 31-33 class – from 530 rubles / m2.

Laminate with a click-lock: class 21-23 – from 480 rubles / m2, 31-33 class – from 570 rubles / m2.

The price, in addition to the class of the laminate, depends on its color.

Substrate under the laminate, depending on the type – from 20 to 160 rubles / m2.

Which laminate to choose

If you are choosing a laminate for an office space or a commercial facility – at least 32nd class. It will be expensive, but will not create a cause for concern for 5-6 years. For residential premises, it is best to choose also a commercial laminate class – at least 31st. Yes, it is more expensive than the laminate of smaller classes – but it will serve many times longer! Do not skimp on the brand – as a result, such savings will cost you more.!

I’m interested in installing laminate flooring in my home, but I’m not sure where to start. Can anyone offer advice on how to choose the best laminate flooring? I’m looking for factors like durability, affordability, ease of installation, and overall appearance. Any tips or suggestions would be greatly appreciated. Thanks!