Recommendation points

- What types of partitions exist

- The nuances of mounting the supporting frame

- Selection and installation of filler

- Application of damper and reflective materials

- Plating rules

- General recommendations

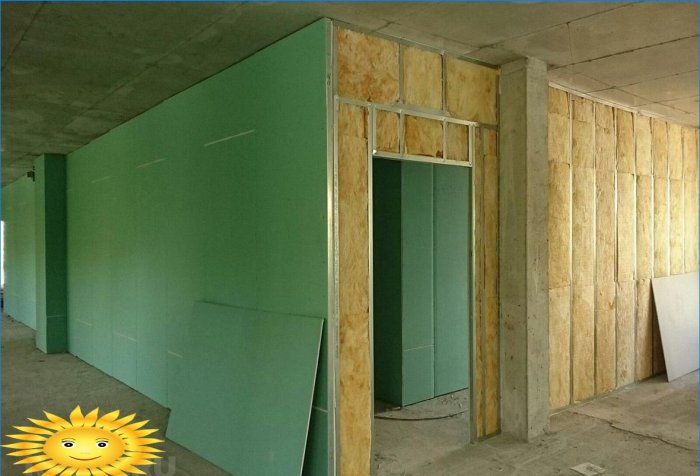

Although partitions made of gypsum plasterboard give complete freedom in planning premises, they have an important drawback – they poorly impede the propagation of sounds. To eliminate such a flaw, we turn to the albums of technical solutions and study how to properly build non-capital partitions with good sound insulation..

What types of partitions exist

There are not so many manufacturers of gypsum plasterboard systems in the world, at least of the same scale as Knauf and Gyproc, as well as Lafarge and USG, which are little known to domestic consumers, although they conquered the North American drywall market. All these giants of the construction industry can rightfully be considered carriers of authentic technology that have managed to maintain its strengths and provide new advantages. In particular, such a childhood disease of drywall partitions as high noise permeability is almost completely cured..

In the classification of partitions, the main characteristics are the width of the bearing profile, its row and density, the thickness and number of sheathing layers, as well as the presence of special protective, separating layers and various kinds of fillers. From the point of view of sound insulation, two types of differences between partitions can be distinguished: those that are provided for by the design, and those that arise from the technology of work.

Among the purely structural nuances, two main ones can be distinguished – the configuration of the supporting frame and the composition of the sheathing pie. The type of filler used, the order of laying the sheets, the layout of the fasteners and, in general, everything that is displayed on the sketches of technical albums also play a role. Almost every manufacturer provides a set of working documentation in which different types of partitions and facings are recommended, including those designed for effective noise damping. The most frequently used solutions are remote double-row placement of profiles, two or three sheathing layers, the use of flexible ties in critical joints or thermal profiles in the crate, the device of damping layers and gaskets.

Soundproof self-adhesive tape

From the point of view of the installation process, the differences are less obvious, but they also determine the sound transmission of the partitions. Here we are talking in general about professional qualifications and compliance with the norms for the fastening step, the ligation schemes for the plates, the method of fastening the supporting frame to the bases. In particular, an experienced installer will always provide for the laying of a sealing tape between the profile and the wall, making sure that the insulation is laid tightly and evenly. During installation, special attention is paid to the sealing of the joints, the formation of openings and the observance of all technological gaps provided for in the assembly instructions.

The nuances of mounting the supporting frame

The absorption of structural and partly airborne noise depends on how correctly the frame is configured and assembled. Methods that contribute to their elimination follow the general principle of preventing the propagation of vibrations and their transmission to adjacent parts of the structure. An important role is played by the overall thickness and massiveness of the partition.

Vibrating suspension for drywall

For example, if you refer to the Knauf documentation, in their classification, individual series of partitions with a noise absorption coefficient of more than 55 dB have the required qualities, which is quite enough for most residential premises. According to table 10 from the album “KNAUF complete systems. Partitions … “these are samples of the C112 series with an increased thickness of the insulation, as well as the entire series of C113, C115 and C116. For the first two versions of the design, noise protection is realized through the use of a larger profile and an increase in the filler layer, in other versions, frame systems with a two-row arrangement of profiles are offered, fastened:

- directly with each other through the gasket;

- jumpers from gypsum plasterboard;

- using flexible links.

Use of vibration damping washers when attaching the profile

USG has an entire catalog dedicated to the topic of acoustic barriers called USG Acoustical Assemblies. It offers a wider range of techniques, for example, the inclusion of damping layers, special intermediate profiles, slotted linings and a wide range of other accessories in the cladding. Unfortunately, it is impossible to implement most of the proposed solutions in local realities due to the lack of the necessary materials on sale; nevertheless, some technical aspects can be adopted. So, quite real methods can be the use of shock-absorbing washers when attaching the guide profile, the acoustic division of the frame into a two-row bearing system, an increase in the pitch of the posts and the correct placement of openings.

Selection and installation of filler

Traditionally, mineral wool is used as a filler for non-capital partitions. This material fully meets the requirements, it provides climatic zoning, but more importantly, it acts as an absorber of mechanical vibrations due to its loose and elastic structure..

In general, there are few tricks for using mineral wool. First of all, you need to decide what density the filler should be. In technical albums, this indicator is not directly regulated, nevertheless, certain conclusions can be drawn from the fact that most manufacturers position cotton wool with a density of 15 kg / m2 as a filler for non-capital partitions3. In practice, this is clearly not enough, insulation with a density of 40-60 kg / m is suitable for normal sound insulation3. It is important to make one reservation here: what matters is the final density of the cotton wool, that is, the degree of compaction at which it will remain after the installation is completed.

The filling of the partition normally performs the function of sound absorption only when it is compressed. This allows it to fill all the space inside the frame, to come into contact with its elements and cladding as tightly as possible in order to effectively take over mechanical vibrations and dissipate them. In this case, excessively dense cotton wool will absorb vibrations worse, transferring them to the closest structural elements. So in this matter, understanding the golden mean is especially important..

Insulation is laid after one side of the partition is sheathed and communications are laid. The insulation must be installed in a spacer, that is, the step of the partitions must be adjusted in advance so that the distance between the uprights is 1.5–2 cm less than the roll width. This is a fairly simple task, given that the necessary tolerances are often laid down in the dimensions of the insulation, you just need to make sure of this. Before laying the insulation, it is stretched a little in the plane of the mat or roll to fluff it, then it is inserted into the cavity of one profile and pulled out a little, pressing it against the outer shelf of the opposite one. All gaps in the corners and seams must be filled with scraps, but without fanaticism, that is, not over-sealing the cotton wool. After that, an insulating film is glued to the profile, preventing the blowing of filler particles into the room, then the installation of the casing is completed.

Application of damper and reflective materials

The professionals have an ambivalent attitude towards all kinds of materials that serve as an acoustic barrier. Some masters have learned to apply them correctly and appropriately, others completely neglect them or, on the contrary, attribute too outstanding properties. To understand the function of the separating layers, you need to make a small excursion into the physics of mechanical vibrations..

In general, noise propagation between two rooms separated by a sealed partition occurs for two reasons. On the one hand, the covering of the partition facing the sound source can reflect it poorly, that is, it absorbs most of the vibration energy, transferring them further into the depths of the cake. On the other hand, sound insulation can be deteriorated by the fact that the partition itself is too dense, that is, when vibration is transmitted between the elements, it is not damped and scattered. As many have already guessed, mineral wool also acts as an acoustic separator, but this is the main obstacle to the propagation of sound, while there may be additional ones:

- Corrugated multi-layer cardboard. Its cellular structure is good for damping vibrations, while the material is quite dense and allows you to evenly alternate between the layers of the skin and the damper.

- Foam rubber and polyethylene foam. These materials are characterized by porosity and resilience, they also contribute well to damping airborne noise, but they are used, as a rule, under the outer layer of drywall.

- All kinds of acoustic membranes, films and non-woven canvases. Mostly they are used at the border of dissimilar materials or to reduce the area of contact. When installing partitions, it makes sense to lay non-woven webs and membranes between the profile and the skin..

- Diffuse plates with a characteristic jagged surface geometry. These materials prevent a dense barrier that has absorbed noise from spreading it from the back. Such materials can be used in combination with a low-density filler, they are glued to the seamy side of the sheathing in the intervals between the posts.

An example of the use of an acoustic membrane for soundproofing a plasterboard wall

In general, the operation of the acoustic layers is quite transparent. Due to their inclusion in the skin, such an effect is achieved that the outer layer reflects well the noise, transmitting a minimum of vibrations inside the partition, which can be effectively absorbed by the filler and the reverse side of the skin. To do this, you must follow the installation order and use the correct mounting scheme..

Plating rules

When forming soundproof partitions, two types of drywall are used. The first is a standard sheet with a thickness of 16 mm, the main material for the construction of non-capital vertical planes. The second type is acoustic drywall, which has a network of dot embossing or through perforation. The essence of the work of such a material is to create an inhomogeneous environment in which mechanical vibrations propagate worse, as well as to reduce the contact area between the skin layers.

Acoustic (perforated) drywall

It is believed that the sheathing of gypsum board partitions with good sound insulation must necessarily be multi-layer. However, this rule does not reflect the essence, because simply increasing the shell thickness is not enough to prevent noise penetration. We will share one universal recipe that has shown good results in practice..

The first layer of drywall is sewn to the profiles with a step of about 20 cm, while the sheathing must be separated from the frame with an elastic tape, for example, made of polyethylene foam. Next, a layer of foam rubber up to 10 mm thick is attached to the formed plane with PVA glue. The joints between the separator canvases must be placed either horizontally or along the line of the profiles. The second layer of gypsum board is sewn so that it is not attached to the supporting system, but to the inner layer of drywall in the gap between the racks. Typically, the mount is two vertical rows of self-tapping screws in a checkerboard pattern at a distance of 15–20 cm from each other. It is important to observe two rules: the total amount of fasteners for the second layer should be twice as high as when attaching the inner layer to the frame, the distance of the fasteners of the second layer from the rack profiles must also be maintained at least 150 mm.

If desired, the concept can be developed by plating in three layers of base material with two spacers. Here, it is better to use corrugated cardboard as a damper under the outer layer: it is denser and better reflects noise. Otherwise, the rules for performing plating are commonplace: maintaining an equal tightening force, carefully recessed self-tapping screws and correct sealing of seams to ensure tightness, which will eliminate the air paths of sound propagation.

General recommendations

The measures described should never be redundant. Isolation from extraneous sounds in living quarters is very important for comfortable living, but if you overdo it on this issue, you can doom yourself to unreasonable costs and loss of usable space. Therefore, you need to understand that different requirements are imposed on the partition between the kitchen and the living room than for the partition separating the bathroom or children’s room..

The problem of high-quality sound insulation is not only technical, much depends on the correct layout, forecasting noise loads by determining the sources and paths of extraneous sounds. Much also depends on the finishing materials. For partitions made of gypsum plasterboard, made according to schemes from technical albums, painting and wallpapering are recommended, while facing with tiles forces the use of hinged fasteners, increase the number of layers and use the capabilities of damper materials.

What are some effective techniques or materials to enhance noise insulation in plasterboard partitions and walls?