Recommendation points

The article describes a description of polymer concrete products, their advantages and composition. You will learn about the main components of this material, its operational and technical properties. We will tell you about the advantages of polymer concrete products, the properties of each component, and also indicate the price of each of them.

Polymers are rapidly conquering not only the finished product market, but also home workshops. Today, these products can not only be purchased ready-made, but also created literally at home. This option is often more convenient and beneficial. Individual elements can be combined and rather complex designs can be made according to individual sizes.

What is polymer concrete

This composition can be called concrete only conditionally. This term is used because of the exceptional strength of the products. The material includes an artificial analogue of epoxy resin and filler. As in other cases of injection molding, materials are assembled by the manufacturer, or rather, the production technologist.

As a rule, in a basic form, the composition varies from the following types of raw materials:

1. Casting resin is a petroleum product with polyesters. It is a thick liquid. The resin itself is inactive, hardening is extremely slow. An acid catalyst-hardener is used for the seal. Distinguish between standard (household), heat-resistant, chemically resistant and transparent resin.

Casting resin prices

| Name | Production | Packaging | Packing cost, cu e. | Cost of 1 kg, cu e. |

| PlastMass PL-3256 (transparent) | Turkey | Flask 18 kg | 86.4 | 4.8 |

| Yarkopol-410 | EU / Russia | Bucket 22 kg | 55 | 2.5 |

| Casting resin 410RA | Russia | Bucket 18 kg | 40 | 2.2 |

| Polimal 127 | Israel / Russia | Bucket 24 kg | 125 | 5.2 |

| Polipol 353 | Turkey | Jar 1 kg | 8 | 8 |

| Polytek EasyFlo 60/95 | USA | Can 7 kg / Bucket 35 kg | 99.5 / 497 | 14.2 |

| average price | 6.15 |

2. Fine heavy aggregate – quartz sand. It is used for massive heavy products by adding it to the solution. Sand provides strength, weight and resistance to weathering. The main area of application is the recreation of historical exteriors: railings, fountains, urns, statues, tombstones, etc. It is also widely used when installing a bulk polymer concrete floor..

Price for quartz sand TU 5717–005–58914756–2007 produced in Russia

| Name | Container | Container cost, cu e. | Cost of 1 kg, cu e. |

| Quartz sand enriched fr. P-12 (0.8-4) | MKP 1 t | 50 | 0.05 |

| Painted quartz sand | 5 kg bag | 3 | 0.6 |

| Quartz sand grade 1k | Big bag 1 t | 32 | 0.032 |

| Quartz sand colored | 15 kg bag | 4 | 0.27 |

| Quartz sand 0.45-0.8 mm for filter pumps | Bag 25 kg | 347.5 | 13.9 |

| Average price (excluding filter) | 0.238 |

3. Fine lightweight aggregate – poraver or similar. You can use crushed expanded clay. It is used for household products – countertops, sinks, as well as for transport equipment – ship and aviation bathrooms and kitchens. One kilogram of PORAVER material (made in Germany) will cost about 0.3 cu. e.

4. Coarse heavy aggregate – marble and granite chips. Products are obtained of exceptional beauty, strength and durability. The charge for this is the weight of the item. The material is not afraid of any overloads, temperatures and acids. Saunas, swimming pools, architectural monuments are decorated with it. Plumbing fixtures, bathtubs, sinks, polymer countertops with crumb look very expensive and serve an unlimited period *.

* Lifetime is not set in real time as the technology has been used for less than 20 years.

Prices for marble and granite chips

| Name | Packaging | Packing cost, cu e. | Cost of 1 kg, cu e. |

| Marble chips | |||

| White marble crumb, fraction 5-10 | Big bag 1 t | 54 | 0.054 |

| Colored marble crumb | Bag 3 kg | 1.5 | 0.5 |

| Rockmelt 52001 | Bag 25 kg | 4,3 | 0.172 |

| Natural colored marble chips | MKP 1 t | 74 | 0.074 |

| Marble chips fr. 10-20 (crushed stone) | MKP 1 t | 40 | 0.04 |

| average price | 0.17 | ||

| Granite chips | |||

| Granite crumb “nut” 1-3 mm | Bag 50 kg / Big bag 1 t | 6/120 | 0.12 |

| Granite chips (crushed stone, elimination) | Bag 50 kg | 6 | 0.5 |

| Rockmelt 52100 | Bag 20 kg | 2 | 0.1 |

| Screening of granite (granite chips) | Bag 40 kg | 4.5 | 0.11 |

| average price | 0.2 |

5. Reinforcing fiberglass mesh. Cost 1 m2 suitable mesh – mesh 5-10 mm, thread thickness 0.5-1 mm, impregnation – will be about 0.1 cu. e.

6. Aluminum hydroxide is the “cement” for the entire solution. Essential for wrapping resin around the aggregate. The cost of this component is approximately the same due to the unchanged composition. The price is influenced by the distance from the place of production (transportation costs). On average, the price for the most popular ALOLT 01 product from Magyar Aluminum (Hungarian Aluminum) is 1.4 cu. e. / kg.

7. Gelcoat (gelcoat) – a finishing coat made of the listed materials, but without a coarse aggregate. It can have many appearance options. Sometimes focused on different types of resistance – wear, temperature, cracks / scratches, chemicals, etc. Sold separately.

Gelcoat price from different manufacturers

| Name | Manufacturer | Packaging | Packing cost, cu e. | Cost of 1 kg, cu e. |

| Maxguard GT HF | Poland | Bucket 1 kg | 5.8 | 5.8 |

| Сristic 252 PA | Latvia | Bucket 1 kg / Bucket 18 kg | 9/135 | 9 / 7.5 |

| Polijel 213F | Turkey | Bucket 22 kg | 135 | 6.15 |

| DEPOL IN 500 | Russia | Bucket 20 kg | 126 | 6,3 |

| Gelcoat Н03Е9005 SZ (Сristic) | Latvia / Russia | Bucket 18 kg | 126 | 7 |

| POLYCOR ISO NPG PA clear 0200 | Turkey | Bucket 5 kg | 39 | 7.8 |

| average price | 6.75 |

8. Composite granules or “chips” – decorative inclusions that give the surface a special look. This material is not included in the budget set of components and requires advanced production – accurate scales, vibration table – and more sophisticated technology. “Chips” are brought to order, it is difficult to find them in free sale.

The listed components are mixed in different proportions to impart the required properties. The result is not only general household products – baths, sinks, countertops, furniture, but also special and industrial products..

Advantages of polymer concrete

When creating new materials, engineers try to combine the properties of already known materials to create a new unique product. Polymer concrete rightfully deserves this title.

From plastic (polymer) he received:

- smooth, pleasant to the touch surface;

- relatively thin products, easy to install;

- easy and accurate processing, including hand tools;

- hygiene, ease of washing;

- simplicity of technology and purity in manufacturing.

From concrete, he inherited exceptional, incredible strength. It is impossible to indicate the exact figure, since it strongly depends on the specific manufacturer and the purpose of the product. But we can certainly say that the weakest (lightweight without reinforcement) polymer concrete in terms of strength is not inferior to wood. Reinforced composition on granite chips will compete with concrete and granite itself.

Polymer concrete sink tests on video

Form for polymer concrete

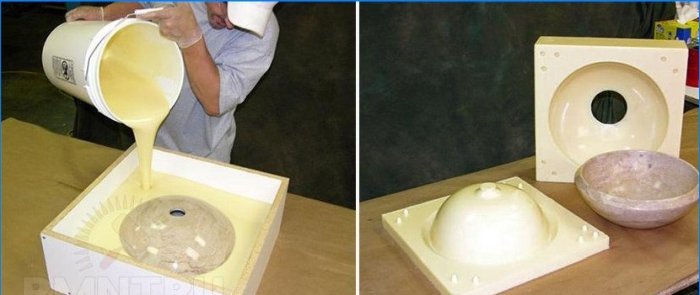

Typically, molds are called dies. The material of this form depends on the number of products that need to be produced:

- From 1 to 10 – MDF, fiberboard, chipboard. By itself, this material is rather loose, but the easier its processing. Coated with varnish or release agent, it can withstand 10 fillings.

- 10 to 30 – plywood. After 30 cycles, cracks appear, the plywood begins to soak, the quality is lost.

- From 30 to 100 (small batch) – silicone, polyurethane. The mold can be made independently from individual components.

- More than 100 (in-line production) – metal. Such forms are made to order in stamping shops. They are expensive but last a long time.

Craftsmen who make custom-made products, cooperate with turning shops, or create molds themselves. There are many courses available to teach this art. Yes, it is paid, but as a result, you can not only acquire a skill, but even open a profitable business.

The cost of a finished product made of polymer concrete, as in other cases, consists of the sum of the cost of components, labor and energy costs. In the case of do-it-yourself “home” production, the final cost will be equal to the cost of materials plus 10-15% for energy and related costs. In the next article, we will talk about how to create a simple polymer concrete product with your own hands in a home workshop..

What are the main differences between polymer concrete and artificial granite? How do their properties differ and what are their respective applications?

The main differences between polymer concrete and artificial granite lie in their composition and properties. Polymer concrete is a composite material made by mixing a thermosetting resin with aggregates. It offers high strength, low permeability, and good chemical resistance, making it suitable for use in industrial flooring, bridge decks, and repair applications. On the other hand, artificial granite is a man-made stone created by binding crushed stone aggregates with resin or cement. It is known for its aesthetic appeal, durability, and low maintenance requirements. Artificial granite finds applications in kitchen countertops, bathroom vanity tops, and architectural cladding. In summary, while polymer concrete is favored for its functional properties in structural applications, artificial granite is preferred for its visual appeal in decorative applications.

What are the key properties and applications of polymer concrete and artificial granite? Can you please provide more information on their durability, strength, resistance to abrasion, and overall performance in various settings? I am interested in understanding the differences between the two materials and their suitability for construction projects.

Polymer concrete is a versatile material that consists of a thermosetting polymer resin combined with aggregates like sand, gravel, or crushed stone. It offers high compressive strength, durability, and chemical resistance, making it ideal for use in construction projects exposed to harsh conditions such as industrial flooring, marine structures, and sewage treatment plants. Polymer concrete is known for its excellent resistance to abrasion, impact, and corrosion, ensuring long-lasting performance in various settings.

Artificial granite, on the other hand, is a composite material made of natural minerals like quartz, feldspar, and silica, combined with resins and pigments. It resembles natural granite in appearance but provides better strength, durability, and resistance to stains and scratches. Artificial granite is commonly used in countertops, flooring, and cladding applications due to its aesthetic appeal and low maintenance requirements.

In terms of durability, polymer concrete typically outperforms artificial granite in harsh environments due to its superior resistance to chemicals and abrasion. However, artificial granite offers a more luxurious appearance and a wider range of colors and patterns, making it a popular choice for architectural applications. Ultimately, the choice between polymer concrete and artificial granite depends on the specific requirements of the construction project and the desired balance between durability, aesthetics, and performance.