Recommendation points

- Clearance, thickness, blockage: determine the parameters of the opening

- Arch options

- Assembling the structure under the arch

- Wireframe Radius Faces

- Completion of the arch construction

Arches and portals from gypsum boards with the correct geometry sometimes seem incredibly complex to design, although they all have the same simple construction principles. Today we will tell you about how to make beautiful and durable drywall arches with your own hands..

Clearance, thickness, blockage: determine the parameters of the opening

The basis for the GKL arch is a frame made of galvanized steel profile. To build it, it is necessary to rely on a number of characteristics of the existing opening.

Height and clearance are vertical and horizontal dimensions, respectively. The final dimensions of the arch depend on them, despite the fact that on the sides the type-setting structure will eat about 40-60 mm and another 100 mm from above. Expanding the opening in advance is a widely used technique unless work is being done on a load-bearing wall..

No less important is the material of the walls, because the reliability of fixing the arch substructure depends on the strength of the supporting base. There are no problems with concrete panels and brick partitions, but openings in walls made of loose materials, such as adobe or shell rock, must first be plastered and reinforced with steel mesh.

Separately, it is worth touching on the theme of arches, which, in a certain sense, are independent of the walls. If both adjacent rooms have gypsum plasterboard cladding along the profile frame, the arch does not need to be fixed inside the opening. For very thin partitions (less than 70 mm), the method of assembling a thickened opening, decorated with columns on the sides, is popular. In fact, there are much more variations in the performance of the arch than it seems.

Arch options

In the usual sense, the arch has two even flat side faces and a semicircular arch. This classic shape sets the standard for simplicity and restraint in style. It is worth remembering that by complicating the shape, each time you doom yourself to additional work – not during the assembly process, but in the routine puttying and sanding. If you are ready to be scrupulous and diligent in the final stage, you can consider more complex options..

First of all, pay attention to the arch with a transom or several through cells above the vault. On the one hand, such a configuration looks light and elegant if there is a pronounced repetition of forms in the arch. On the other hand, the cells can become a potential “dust collector”, so they must be finished with washable covers and periodically taken time for cleaning..

If there is a transom, the arch itself may not have a round vault. Instead, a simple rectangular portal of a strict form is formed, which is decorated with a wide through niche on top. Such solutions are very well combined with indoor landscaping and point light sources mounted in a horizontal partition..

Of more laconic forms, you can offer arches with a tilted arch or only one rounded corner. They can dilute the monotony of long corridors with low natural light..

Double and triple arches, which have several vaults of different heights, thicknesses and radius of rounding, are somewhat more original. Multilevel vaults, as well as dedicated imposts, pylons, capitals and castles, are assembled on top of the basic structure, which simplifies the implementation of complex architectural delights.

Assembling the structure under the arch

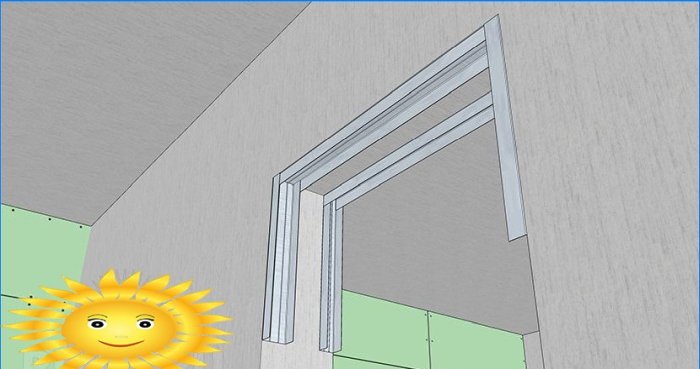

The base for the arch is a rectangular frame, edging the opening and serving as a reliable basis for fixing all subsequent elements. As mentioned above, depending on the presence of cladding on adjacent walls, the substructure is assembled in different ways..

In a clean opening, one or a pair of guide profiles is mounted on each face. With a minimum wall thickness of 50 mm, they are mounted along one guide profile of the same width. With a width of 50 to 100 mm, one such large profile is installed flush with one edge of the opening, and an additional PN profile with a width of 27 mm is mounted on the other.

With an arch thickness of 100 mm or more, one of the guide profiles is changed to a 100 mm one, using a second, additional profile of different widths. It is important that at least one of the lines of the substructure is made with a 50 mm or more massive profile. This will allow the use of a flexible (segmented) post profile of the appropriate size that will be securely fixed in the guide system. This explains the unpopularity of the PS-60 and PN-27 set, since the relative position does not allow them to be technologically docked..

At the very top of the opening, the guide profiles are connected by a horizontal crossbar, which is not rigidly attached to the arch of the base. To dampen vibration noise, the frame system is mounted on a polyethylene foam lining. Looking ahead, let us clarify that the lower part of the vertical guides can be cut off after assembling the arch to save the final width of the arch, however, in the case of a set of false planes along the side faces, you need to insert another pair of the same corresponding height into the guide profiles, placing them with shelves towards each other.

Wireframe Radius Faces

The supporting base for the vault and other surfaces of a radius shape is a flexible post profile or, in the worst case, a segment of a conventional post profile with split side shelves. If the arch includes convex radius elements, using the rack-mount type will not work because of the edges on the shelves – they will not fold tightly when bent, and this will complicate the sheathing of the side planes.

The question remains: how to bend the profile forming the shape exactly and at the same time duplicate the bend on the opposite side of the arch? Here, a tricky trick is used: first, two identical fragments of the skin are cut out of the gypsum board, which are precisely marked and cut out according to a common template. They are attached to the side posts of the subsystem and the upper crossbar, aligning with each other with a rack level.

After, along the contour of the figure, from the inside, flexible segments of the frame are screwed, which are nested between the shelves of the guide profiles. If the side parts of the arch remain without cladding, at this stage the substructure is cut off with a small margin, and the protruding shelves are folded over the edges of the arch frame and additionally reinforced with self-tapping screws.

The covering of the sides of the arch, including the curly one, is done in exactly the same way. The transom and through niches are first cut out in sheets covering the vault, and then reinforced from the inside with pieces of PN-27 or larger. After the completion of the assembly, the two structures are connected by short jumpers, due to which the thickness of the arch is adjusted in each specific place..

Completion of the arch construction

Sheathing the frame is not difficult, with the exception of some specific situations. For example, if the covering of the vault of a wide arch cannot be made with a solid sheet, it is divided into two halves, fastened with a CD-60 piece. In this case, you need to manage to put the profile on the inside, when one of the planes is already sewn, although the thickness of the arch almost always allows.

Internal surfaces can be sheathed in small pieces and trims, but the more joints, the longer it will take to properly reinforce them. Curved surfaces, as usual, are sheathed with soaked soft plasterboard, which must then be completely dried. Before leveling puttying, the installation of corner profiles (first flexible, then straight) and strengthening of the joints between the sheets is performed.

After filling and sanding, the inner surfaces of the arch are best treated with acrylic or water dispersion washable paint. It is advisable to cover the external parts with the same finish that is used on the sections of the walls adjacent to the arch. If it is not possible to neatly bring dissimilar materials at the corners – use foam fillets of different shapes, but purchase them in advance to determine the optimal rounding radii.

Can you please provide step-by-step instructions on how to create a drywall arch without hiring a professional? I am particularly interested in understanding the process of shaping the arch, attaching it to the wall, and ensuring its stability. Any tips and advice would be greatly appreciated!