Recommendation points

- How Blind Rivets Work

- Bonding technique

- Application of rivet guns

- Threaded rivets

- Manual or electric

A quick and very strong connection can be achieved using blind rivets, installation with them becomes simple, safe and very convenient. We will talk about the existing types of rivets, their advantages, disadvantages and rules for working with them..

Although the principle of operation and design of different rivets is not very different, there are many tools for them. As well as the features of the installation process.

How Blind Rivets Work

Most often, a riveted joint is used to connect two flat parts, while the width of the place of their contact is usually 3-4 or more times greater than the thickness of the workpieces. The most telling example is two 4×40 mm steel strips folded back to back. At any point of contact, the width is 40 mm, which is 5 times more than 8 mm – the own thickness of the parts.

The rivet itself consists of two parts. The core is in the form of a rod, at one end of which a small ball is fixed. The rivet sleeve has the form of a hollow tube, one side of which is expanded to a semicircular head with a shelf width equivalent to 2/3 of the outer diameter of the sleeve.

Typically, the tube is made of a softer metal so that the core deforms the underside of the rivet when pulled. This achieves a very good compression of the parts, while the connection can remain mobile, maintain a slight elasticity and excellent strength properties..

Bonding technique

For fastening two parts, holes with a common clearance must be made in them. This is, in fact, the only way to position parts relative to each other, so if an exact fit is required, proceed as follows. First, holes are accurately marked on one side of the connection, then the parts are firmly fastened with clamps and drilled through.

In practice, this accuracy is rarely required; it is much more important to choose the correct hole diameter. It should be 2-3 tenths more than the thickness of the rivet sleeve, while seizure marks and drill marks must be cleaned out, but only without countersink.

A rivet is inserted into the through hole and the core is pulled out with a tool. The ball deforms the protruding part of the sleeve, forming folds that press the parts against the side of the head and secure them together. The core rod has a groove, therefore, with excessive force, the rod breaks off, while the ball is securely clamped in the folds of the sleeve.

In reality, one of the parts to be joined often has a factory perforation, so the diameter of the rivet, as well as its length, is selected locally, and not vice versa. If the hole diameter is much larger, it is highly likely that the rivet will simply push inward and will not provide proper compression. On the contrary, if the hole size is too small, it will make it difficult to insert a rivet into it and slow down the installation process..

The length of the rivet sleeve should be 6–8 mm longer than the total thickness of the parts to be joined. If the rivet is shorter, the ball will not be squeezed from all sides and will fall off, and a too long tail of the sleeve will burst when deformed.

Application of rivet guns

Blind rivets require a special but inexpensive tool. The operating principle of riveters is simple. The tail of the rivet is passed through a guide sleeve, the hole of which corresponds to the thickness of the rod, plus or minus 1.5 mm. Inside there is a collet clamp, which, with pressure on the handles, clamps the tail and pulls it out with a decent effort.

Usually riveters have 2–5 replaceable sleeves with different diameters for the corresponding rivet sizes. The size of rivet guns depends on the diameter of the rivets used, the larger it is, the higher the force required to pull out the core, and the length of the handles increases accordingly. For rivets for holes up to 5–6 mm, a tool is used in which the handles are located perpendicular to the axis of the rod. More massive fasteners can be confidently pulled out only with the help of lever rivets, arranged according to the principle of a bolt cutter.

Despite the typical design of all pistols, their choice is great and the price for them varies greatly. First and foremost, tool makers are fighting for its durability and make collet jaws and head bodies from more wear-resistant and harder materials such as Cr-Mo steel. All parts of the hinges and handles must be made of high quality cold-formed steel, and not bolts, but carbide pins with retaining rings, must be installed on the moving parts..

The shape of the handles and their ergonomics are no less important; the presence of pads made of soft material with slots for fingers makes the grip of the tool more reliable and facilitates the installation process. Of course, these factors are not so important when the tool is rarely used for domestic purposes, but frankly cheap pistols are still not worth buying: very often the handles of a cheap Chinese-made tool, the so-called NO NAME, break corny. We recommend that you pay attention to the tool of renowned manufacturers, whose product line is not limited to 2-3 names of tools.

Threaded rivets

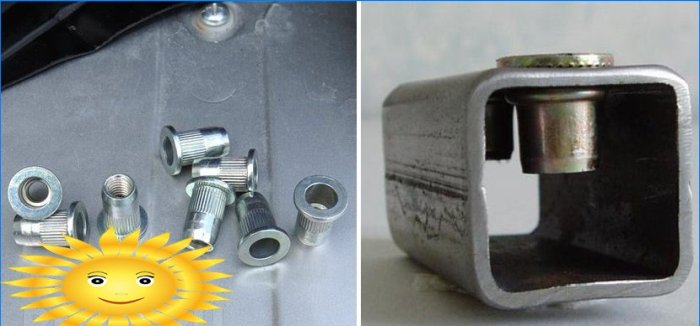

We will separately mention another type of rivet fastener, which is used when necessary to make the connection more accurate, reliable and aesthetically pleasing. No less often, such rivets are used when it is necessary to make threads in thin and fragile panels or sheet materials..

The threaded rivet is a thin hollow tube with an external flare on one side and an internal thread on the other. In the area between them, the metal is slightly thinner, so if you screw the hairpin into the thread and pull it towards you, it will gently crumple and firmly press the part.

Externally, threaded rivets are similar to blind rivets and have the same quality requirements. This type of fastener is made of different metals and alloys, including fairly hard ones. The hole for threaded rivets must have a countersink: the upper side of the rivet is pressed into the groove formed by it, so the fasteners will not protrude above the surface of the part.

Manual or electric

All types of rivets are manual and mechanized, in the latter the source of driving force can be electricity, hydraulics or compressed air.

Hand riveters work very well on site. They are comfortable enough for frequent and short-term use. There are three tool classes for rivets of different thicknesses:

- One-handed for rods up to 1.5 mm.

- Two-handed with side-mounted handles for rods from 1.5 to 3.5 mm.

- Two-handed with extended longitudinal handles with a rod thickness of more than 3.5 mm.

Electric and battery rivets should be used for large volumes of work: 150-200 rivets, even for a trained hand, is a very serious load. If in professional activity you often have to use this type of fastener, the electric tool will pay for itself many times over, moreover, the component parts of the mechanism in it live 5-6 times longer than in manual.

As for pneumatic and hydraulic tools – his lot is to work at stationary equipped places, for example, at service stations and in assembly workshops.

Hi! I’m curious about manual riveters. Can you please guide me on how to choose the right one for my needs? Also, could you provide some tips on using a manual riveting tool effectively? I’m eager to learn and would appreciate any advice or recommendations you can offer. Thanks in advance!