The vast majority of homeowners do not know what a thickness gauge is and have never encountered such equipment. However, situations are different. Site article Our site will be useful to those who plan construction or repairs using lumber or want to make furniture with their own hands.

Immediately, we note that you should not confuse the thicknessing machine with the measuring device of the same name! These are completely different tools. Conventional hand planers shown in the photo above are intended simply for marking before cutting, drawing dividing lines. For example, a dovetail planer allows you to mark the places of future grooves. These are simple hand tools that anyone can use in their work. We will talk specifically about thicknessing machines, much more complex equipment..

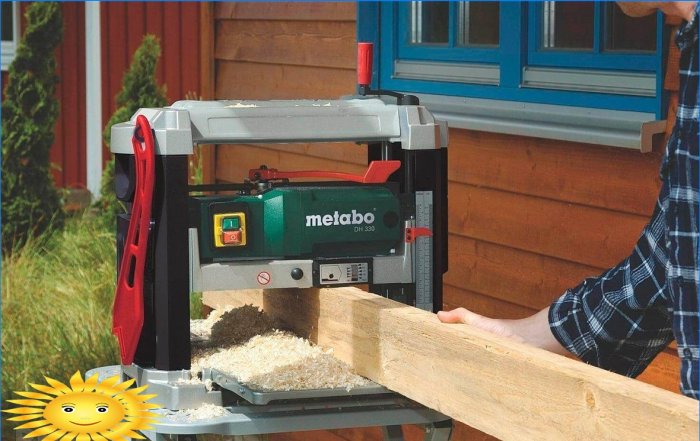

The main purpose of the planes is the final planing of boards according to a given thickness. The board goes through the machine and comes out with the desired thickness, with a perfectly smooth and even surface. As a result, you get boards of the same thickness, for example, for making various furniture, building a fence, and so on. You never know where smooth lumber is useful on the farm!

Important! The planer will not make a crooked board even! It slices the top with its wide shaft with sharp blades. That is, one side of your workpiece must be flat initially, so that the process runs normally.

All planes are divided into stationary, powerful, used in production, and portable, mobile. It is the last option that is suitable for home craftsmen.

The thicknessing tool is powered by a powerful motor, which, thanks to a belt drive, rotates a shaft with blades. In order to get the board of the desired thickness at the exit, you should use the adjustment mechanism – it has a scale in inches and millimeters. Modern machines are equipped with an automatic feed of the workpiece: in front of the knife shaft, they have two rollers that move the board. Average speed – 7-8 meters per minute.

You just need to put the workpiece on the table on which the thicknessing tool is installed, feed it into the machine and pick it up from the opposite side of the already processed one. Some models of machine tools can be adjusted in speed: at low you will get an ideal quality result, at high – speed up the work process.

Technical characteristics of thicknessing machines:

- Average power 1.5-1.8 thousand W;

- The caliber, that is, the maximum thickness of the workpiece and the planing width are different, depending on the dimensions of the machine itself. Most often, for stationary planes, the maximum width is 330 millimeters, and the thickness is 152 millimeters. By the maximum thickness, you can determine how wide the board you can put on the edge to pass through the machine;

- The maximum planing depth, that is, the layer that will remove the thickness gauge from the wood in one run, does not exceed 3.2 millimeters on average;

- Shaft rotation frequency – 8-10 thousand revolutions per minute.

Important! There are thicknessing machines that process both sides of the board simultaneously. They are called that – bilateral. They are much more expensive, usually used only by professionals and in production. There are also planing and thicknessing machines, convenient equipment for furniture makers and joiners.

The most popular brands of planers in our country: JET, Makita, Sturm, Patriot, Metabo. Different prices. You can find portable desktop models at a price of about 20 thousand rubles, you can buy a powerful floor model for 200 thousand rubles.

By the way, the portal described why a gage is needed in a series of articles dedicated to making a kitchen cabinet with your own hands..

What is the purpose of thicknesser machines and how are they typically utilized?

What is the purpose of thicknesser machines and how are they used? I’m curious to learn about their functionality and the process involved in operating these machines.

Thicknesser machines are used in woodworking to reduce the thickness of wooden boards or panels to a specific measurement. They are commonly used to create uniformly thick pieces of wood for various woodworking projects. The process of operating a thicknesser machine involves feeding the wood through a set of rotating blades that remove material from the surface until the desired thickness is achieved. The machine allows for precise and consistent thickness measurements, making it ideal for creating custom pieces of wood for furniture, flooring, and other woodworking applications. Thicknesser machines are a valuable tool for woodworkers looking to achieve precise and efficient results in their projects.