The content of the article

- What is bark beetle plaster

- Composition

- Views

- Application technology

- Facade decoration

- For interior work

- Will establish

- Knauf

- Ceresit

- Bergauf

- Baumit

- AHT

- Bayramix

- Duf

- De luxe

- How to choose

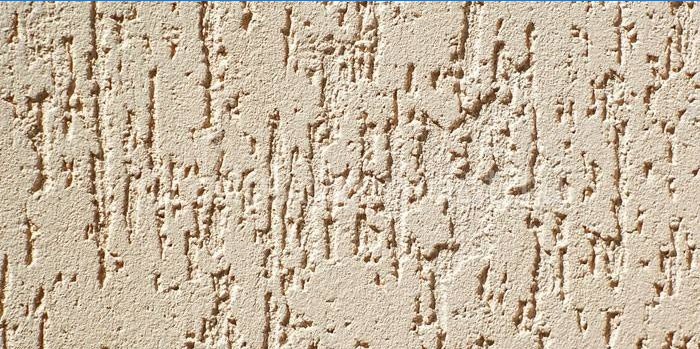

Unusual decorative finish of the facade or internal walls will help to make bark beetle plaster. This material got its name due to its similarity after application to the appearance of wood damaged by a woodworm beetle. The bark beetle finish also has good performance. It is especially resistant to precipitation and aggressive chemicals, is frost-resistant and does not fade in the sun. You will learn about application, characteristics and selection criteria from the article below..

What is bark beetle plaster

The bizarre patterns that the beetle grinder leaves on a cut of wood, and served as the basis for creating plaster with the unusual name Bark beetle. It is a western development, and in domestic construction appeared at the end of the 20th century. This is a unique finish for interiors and facades. The secret of the decor is the presence of small pebbles in the solution. Such plaster is no less popular than Danish, Venetian, “Lamb” and “Fur Coat”.

Composition

The first component is the astringent component, which is the basis. It can be cement with the addition of polymers or polymer resins such as latex, silicone and acrylic. The specific type of cementitious base determines the characteristics of the plaster. The second component is the grain, which provides the appearance of a texture with grooves. Its main parameter is the size of the fraction. The larger the seeds, the deeper the grooves will be. This composition of the plaster is characterized by increased consumption. In general, the grain fraction is always indicated on the package.

Views

Most manufacturers offer a wide variety of bark beetles. There are such plasters for the facade or interior work. Separately, the category of universal compounds stands out. There is a classification according to the level of preparation for application – stucco in the form of a suspension, already painted and packaged in buckets, and a dry mixture with granules, packed in a bag. The latter is much more difficult to tint. Plasters are also divided according to the binder:

- Mineral The basis is cement and lime. They are cheap, but very practical. They are easy to apply, even with your hands..

- Silicate. It is a liquid glass with high compressive strength, durability and vapor permeability. The only drawback is the high price.

- Acrylic They include acrylic resins. Such mixtures have good characteristics both for facade cladding and for interior walls. The downside is poor resistance to sunlight.

Application technology

An important condition for obtaining a beautiful coating is the correct technology for applying bark beetle. You can use it on different surfaces – drywall, brickwork, concrete and chipboards. Before applying the plaster to the wall, it is cleaned of the remnants of the previous finish, then fill the cracks with putty, and after drying with a primer, if this is the interior.

Then, in a clean container with water added in the required dosage specified in the instructions, the dry component of the mixture is gradually poured and mixed until uniform. Then the mass is left for 10-15 minutes under the lid. The technique of plastering bark beetle includes the following steps:

- Using a grater or spatula, holding them at an angle of 60 degrees, apply the mixture to the wall.

- Then, in circular motions or up-down or side-to-side movements, smear the mass with an even layer, remove excess and immediately distribute to a new area.

- Mix the solution thoroughly every five minutes..

Facade decoration

More often the facade is decorated with bark beetle. This is due to the good resistance of the material to weathering. In addition, at a price relative to the regions of Moscow and St. Petersburg, plaster belongs to the category of available materials. Its advantage is in a wide range of colors, so you can easily find the right one for your home. Facade plaster often consists of cement and marble chips, but there are other types of it..

Exteriorwell decorative plaster, Founders

Price:

- 25 kg – 828 rubles.

Characteristics:

- adhesion to the base – 0.65 MPa;

- vapor permeability coefficient – 0.1 mg / mchPa;

- frost resistance – 50 cycles;

- operating temperature – from -50 to +65 degrees;

- shelf life – 12 months.

Pros:

- variety of drawing – city, classic bark beetle, rain;

- ease of application;

- weather resistance.

Minuses:

- no.

Weber-Vetonit min Bark beetle

Cost:

- 25 kg – 559 r.

Description:

- frost resistance – 100 cycles;

- consumption – 2.6-2.8 kg / m2;

- grain size – 2 mm;

- adhesion strength – 0.35 MPa;

- binder – lime, cement;

- color – gray;

- shelf life – 12 months.

Pros:

- not combustible;

- vapor permeable;

- for painting.

No cons

For interior work

Less stringent requirements are placed on the bark beetle for internal work. The main condition is the ability of the decorated surface to adhesion. On smooth metal or glass materials, the plaster will not stick. The advantage of this type of decoration for interior walls is the ability to create a variety of types of patterns. Thanks to this, you can arrange the interior in any design option.

Bark beetle decor UNIS

Price:

- 25 kg – 370 r.

Description:

- vapor permeability – 0.1 mg / mchPa;

- drying time – 2-3 days;

- consumption with a thickness of 2 mm – 3.5-4.5 kg / m2;

- grain size – no more than 2 mm;

- White colour;

- shelf life – 12 months.

Advantages:

- “Breathable” coating;

- not scratched;

- can be painted repeatedly.

Disadvantage:

- no.

Knauf Diamond Bark beetle grain 1.5 mm

Cost:

- 25 kg – 370 r.

Description:

- vapor permeability coefficient – 0.1 mg / mchPa;

- consumption – 2.5 kg / m2;

- grain size – 1.5 mm;

- colors – white;

- operating temperature – from -50 to +65 degrees;

- shelf life – 12 months.

Advantages:

- variety of design;

- protection and increased strength;

- possibility of application by machine.

Disadvantage:

- high consumption.

Will establish

The main function of the Founder finish is to create not just a decorative, but also a protective layer. Most often used in systems with rigid fastening of insulation. Such decoration is recommended for use in cultural and leisure centers, lobbies, hallways, administrative buildings and public places. The base may be cement and cement-lime plasters and putties, foam and aerated concrete.

Exterwell OS-1,0 WK, FOUND, white (colorized)

Price:

- 25 kg – 488 r.

Characteristics:

- vapor permeability – 0.1 mg / mchPa;

- coupling strength – 0.65 MPa;

- consumption – 1.6-1.8 kg / m2;

- grain size – 1.0 mm;

- frost resistance – 50 cycles;

- operating temperature – from -50 to +65;

- shelf life – 12 months.

Pros:

- variety of design;

- ease of application;

- the ability to paint in any color.

Minuses:

- no.

Exterwell OM-2.5 WK, Founder, Superwhite

Cost:

- 25 kg – 889 r.

Characteristics:

- vapor permeability coefficient – 0.1 mg / mchPa;

- adhesion – 0.65 MPa;

- consumption – 1.6-1.8 kg / m2;

- granularity – 2.5 mm;

- frost resistance – 50 cycles;

- operating temperature – from -50 to +65;

- shelf life – 12 months.

Advantages:

- variety of design;

- ease of application.

Disadvantage:

- coarse fraction is more suitable for outdoor applications.

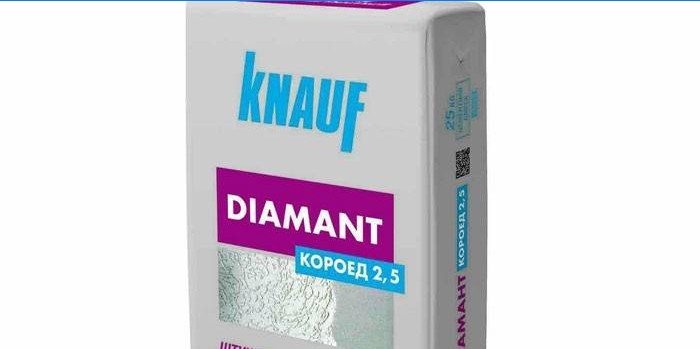

Knauf

One of the leaders in the market of finishing materials is Knauf. More often represented by compositions in the form of a dry mixture, which must be prepared. To do this, it is diluted in certain proportions with water. Its quantity is indicated in the instructions on the package. The size of the fraction varies from 1.5 to 2.5 mm, so the product can be used both inside and outside.

KNAUF DIAMOND BARRY GRAIN 2.5 MM

Price:

- 25 kg – 370 r.

Characteristics:

- vapor permeability coefficient – 0.1 mg / mchPa;

- view – cement;

- consumption – 3.5 kg / m2;

- granularity – 2.5 mm;

- frost resistance – 50 cycles;

- expiration date – 12 months.

Pros:

- resistance to shock and vibration;

- the possibility of applying by machine;

- high quality.

Minuses:

- high consumption.

KNAUF DIAMOND GRAIN 1,5 MM

Cost:

- 25 kg – 370 r.

Description:

- vapor permeability coefficient – 0.1 mg / mchPa;

- view – cement;

- consumption – 2.5 kg / m2;

- grain size – 1.5 mm;

- frost resistance – 50 cycles;

- expiration date – 12 months.

Pros:

- resistance to shock and vibration;

- the possibility of applying by machine;

- special ductility;

- high quality.

Minuses:

- no.

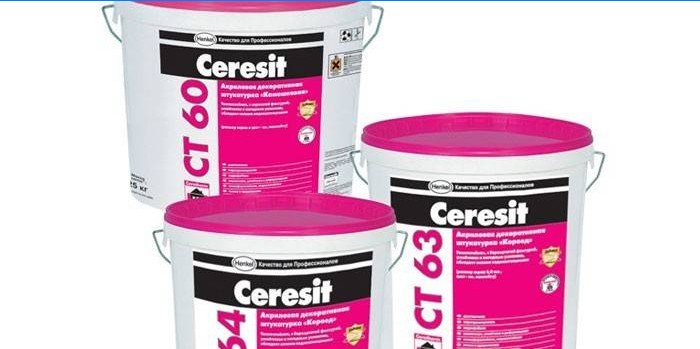

Ceresit

Among polymer compositions, Bark beetle Ceresite is especially good for reviews. But due to the improved quality of the finish, it has a higher cost. In addition to ready-made options, Ceresit products are also presented as dry mixes. They belong to the category of mineral. The variety lies in a wide range of textures, so you can choose a larger or smaller finish.

Ceresit CT 60, CT 63, CT 64

Price:

- 25 kg – 2300-2400 r.

Description:

- view – mineral;

- consumption – 2.5-4.0 kg / m2;

- granularity – 1.5-3.0 mm;

- frost resistance – 100 cycles;

- service life – at least 10 years.

Pros:

- ready to use;

- strength and durability.

Minuses:

- no.

Ceresit CT 35 “Bark beetle”

Cost:

- 25 kg – 2300-2400 r.

Characteristics:

- view – mineral;

- consumption – 3.0-4.0 kg / m2;

- granularity – 2.5-3.5 mm;

- frost resistance – 75 cycles;

- service life – at least 10 years.

Advantages:

- environmentally friendly;

- hydrophobic;

- shockproof.

Disadvantage:

- high consumption.

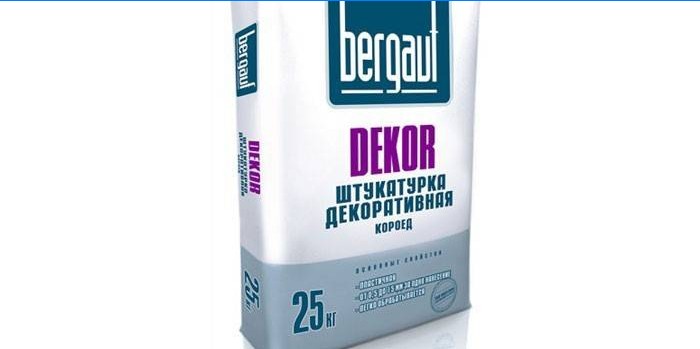

Bergauf

For indoor and outdoor use, you can use products from Bergauf. It is a white dry mixture based on a cement binder. Other components are chemical additives, marble chips and mineral filler. The consumption of the mixture is high – for 1 square meter it will take about 2.5-3 kg. Another advantage is that you can paint the finished finish or paint the material in bulk.

BERGAUF DECOR (Bergauf)

Price:

- 25 kg – 545 r.

Characteristics:

- astringent – cement;

- strength – M100;

- consumption – 2.5-3.0 kg / m2;

- grain size – 2.5 mm;

- operating temperature – from -50 to +70;

- frost resistance – 50 cycles.

Pros:

- environmentally friendly;

- the ability to paint several times.

Minuses:

- high consumption.

Bergauf DEKOR WINTER

Cost:

- 25 kg – 468 r.

Characteristics:

- astringent – cement;

- strength – M100;

- consumption – 2.5-3.0 kg / m2;

- granularity – 2.5-3 mm;

- operating temperature – from -50 to +70;

- frost resistance –75 cycles.

Pros:

- suitable for thermal insulation of facades;

- application possible at low temperatures.

Minuses:

- no.

Baumit

Ready-to-use Baumit finish is sold. It is a paste-like silicone mixture that can immediately be applied to the wall. It is used in the thermal insulation system of facades in combination with expanded polystyrene, cork wood or mineral wool. It has many advantages – from abrasion resistance to self-cleaning effect.

Silicone plaster BAUMIT SILIKONTOP 2 R SN 10, WOODEN

Price:

- 30 kg – 485 r.

Characteristics:

- vapor permeability – 0.020 mg / mchPa;

- consumption – 2.5-4.2 kg / m2;

- grain size – 1.5-3 mm;

- frost resistance –75 cycles.

Pros:

- low pollution;

- just applied;

- washable.

Minuses:

- no.

BAUMIT SILIKATTOP 2 R SN 10

Cost:

- 25 kg – 485 r.

Description:

- vapor permeability – 0.020 mg / mchPa;

- consumption – 1.8 kg / m2;

- drying time – 24 hours;

- grain size – 2 mm.

Advantages:

- ready for use;

- for manual or machine use;

- low pollution.

Disadvantages:

- no.

AHT

Another type of roller, i.e. relief decoration presented by the company VGT. Refers to acrylic compositions, which are much more difficult to apply, but they look very beautiful. Another advantage is that there is no need to breed it, because the mixture is already ready for application. For sale is available in white, so pre-tinted composition.

VGT Roller decorative plaster with bark beetle effect

Price:

- 18 kg – 1490 r.

Characteristics:

- consumption – 0.3-0.5 kg / m2;

- drying time – 48 hours;

- dilution with water – up to 5%;

- grain size – 1.5-2.5 mm.

Advantages:

- enough to cover a large area.

Disadvantages:

- no.

VGT Roller decorative plaster with bark beetle effect

Cost:

- 9 kg – 790 r.

Description:

- vapor permeability – 0.020 mg / mchPa;

- consumption – 0.3-0.5 kg / m2;

- drying time – 48 hours;

- dilution with water – up to 5%;

- grain size – 1.5-2.5 mm.

Pros:

- enough to cover a large area.

Minuses:

- no.

Bayramix

A thicker layer is applied mixture from Bayramix. It is recommended for use when decorating facade insulation systems made in the “wet” type. Suitable for application on virtually any surface. It can be concrete blocks, cement plaster, gypsum and plasterboard, all types of wooden surfaces. More often, such decoration is used in public buildings..

Bayramix Baytera (Bayramiks Baytera) – Thick plaster with mineral filler

Cost:

- 20 kg – 1890 r.

Description:

- consumption – 2.5-4.0 kg / m2;

- drying time –24 hours;

- grain size – 1.5-2.5 mm.

Pros:

- 16 color schemes;

- hides minor defects;

- High strength.

Minuses:

- no.

Bayramix Baytera (Bayramix Baytera)

Cost:

- 20 kg – 1890 r.

Characteristics:

- consumption – 2.5-4.0 kg / m2;

- drying time –24 hours;

- grain size – 0.25 cm.

Advantages:

- 16 color schemes;

- hides minor defects;

- High strength.

Disadvantages:

- no.

Bayramix baytera

Price:

- 25 kg – 2570 r.

Description:

- consumption – 2.0-3.0 kg / m2;

- drying time –24 hours;

- grain size – 0.15 cm.

Pros:

- 16 color schemes;

- hides minor defects;

- High strength.

Minuses:

- no.

Duf

For places with increased operational load, Duf products are recommended. The list of premises includes offices, halls, corridors, landings. The walls in them can be from any materials – plywood, gypsum boards, particleboard, concrete, fiberboard. As a result, the surface becomes more resistant to moisture, steam and mechanical stress..

Dufa REIBEPUTZ 15 D 11 m textured

Price:

- 15 kg – 743 r.

Characteristics:

- consumption – 0.4 kg / m2;

- tinting – Dufa MIX;

- grain size – 0.12-0.18 cm.

Advantages:

- suitable for thermal insulation;

- shockproof;

- crack resistant.

Disadvantages:

- no.

Dufa Reibeputz 25 “Bark beetle” 2.5mm

Cost:

- 25 kg – 2100 r.

Description:

- consumption – 0.4 kg / m2;

- tinting – Dufa MIX;

- grain size – 0.22-0.28 cm.

Pros:

- easy to apply;

- reliable;

- suitable for facades and interiors.

Minuses:

- no.

De luxe

From acrylic mixtures, products from the company De Luxe have proven themselves well. It is intended for several types of work at once – the decoration of facades and interiors, the installation of thermal insulation systems. Available in two forms. The first is a white mixture with the possibility of subsequent tinting, and the second is a ready-made plaster, tinted by the manufacturer in accordance with RAL.

ACRYLIC De Luxe

Price:

- 25 kg – 2100 r.

Characteristics:

- consumption – 1.9-3.6 kg / m2;

- base color is white;

- operating temperature – from -50 to +50;

- adhesion strength – 0.5 MPa;

- grain size – 0.15-0.3 cm.

Pros:

- easy to apply;

- good vapor permeability;

- wear resistance.

Minuses:

- no.

How to choose

To choose the right bark beetle plaster, you will have to consider a number of factors. The main ones are as follows:

- Release form – dry mix or ready-made. In the latter case, the composition includes synthetic silicone or acrylic fillers, which are given ductility. This is not characterized by a dry mixture. In addition, it still needs to be pre-cooked..

- Type of composition. Acrylics look a little more attractive, but at the same time more difficult to apply. In addition, they are more expensive. It is much easier to work with dry gypsum-cement composition, but longer, because it needs to be prepared.

- Grain size. The flow rate of the mixture will depend on this. Coarse-grained types are suitable for finishing facades, and fine-grained ones are suitable for interior decoration..

- Manufacturer and cost. Bark beetle is produced by many companies, but it is better to make a purchase from trusted and well-known. It is important to choose only from the category affordable to you. In addition, you can monitor promotions, discounts and sales. You can order the material in the online store with delivery by mail. Another option is to buy directly at the construction department store..

Can anyone recommend a specific bark beetle plastering technology for both exterior and interior use? I’m interested in learning more about the different types available, their consumption rates, and some reliable manufacturers in the market. Any insights or recommendations would be greatly appreciated!

One specific bark beetle plastering technology recommended for both exterior and interior use is the lime-based plaster. Lime plaster has natural properties that make it resistant to bark beetles and other pests. It is an eco-friendly option that allows the walls to breathe, preventing moisture build-up and subsequent infestations. Consumption rates may vary depending on the desired thickness. Some reliable manufacturers in the market include Earthborn, Saint Astier, and Finishing Lime Ltd. These companies are known for producing high-quality lime plasters suitable for various applications. Conducting further research and contacting these manufacturers directly can provide more detailed information and insights about their specific products.

One highly recommended bark beetle plastering technology for both exterior and interior use is from a company called BARKitecture. They offer a variety of options including traditional bark beetle plasters, innovative designs, and custom solutions. Their products are environmentally friendly, durable, and easy to apply. In terms of consumption rates, it depends on the specific type of plaster being used but generally, they are cost-effective and long-lasting. Other reliable manufacturers in the market include EcoCrete and Biodecor. It is advisable to do further research and contact these companies for more information and specific recommendations tailored to your project needs.

One popular bark beetle plastering technology for both exterior and interior use is the cork plaster. Cork plaster is a sustainable and eco-friendly option that offers excellent insulation properties. It is available in different textures and colors to suit various design preferences. The consumption rate of cork plaster varies depending on the thickness and size of the area to be covered. Some reliable manufacturers of cork plaster in the market include Granorte, Novacork, and Amorim. I recommend exploring these options further to find the best fit for your project.

I’m interested in learning more about the bark beetle plastering technology. Could you provide a brief overview of the different types available for both exterior and interior use? Additionally, I would appreciate some insights on the consumption rate and any recommended manufacturers in the market. Thank you in advance for your help!