Recommendation points

- Most common materials

- How not to spend extra money

- How to take measurements

- Installation of postforming and wooden countertops

- Installing an assembled and one-piece worktop

Along with the fronts, the kitchen worktop forms the basis of the aesthetics of the kitchen unit. At the same time, additional requirements are imposed on the working surface in terms of practicality and wear resistance. Today Our tips site will tell you which worktop is better to choose and how to install it correctly.

Most common materials

Most modern kitchens are individually designed so that the furniture set forms a single whole with the decoration of the room, tightly adjoining adjacent surfaces. However, before proceeding with the development of the configuration of the countertop, you should choose the material of manufacture in order to take into account the peculiarities of its processing and methods of making connections..

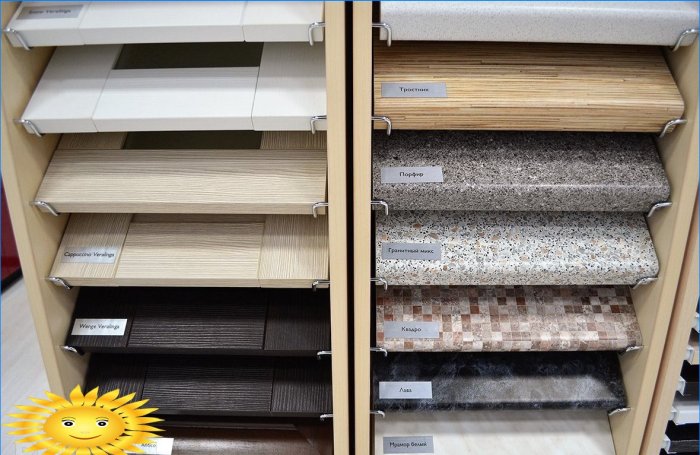

If you do not take into account such exotic options as glass or tile cladding, there are not so many most popular materials for making countertops:

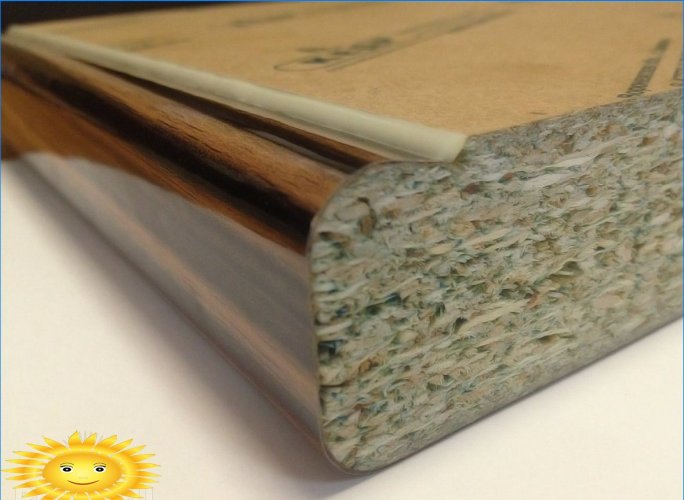

- Postforming is a budget type of countertops. It is a chipboard laminated with plastic. I found bad fame because of the low thermal and moisture resistance, although this is more a matter of the price and quality of the plastic and chipboard base. Preference should be given to a coating of the HPL type, the board should have a moisture resistance class P3, or better – P5, which provides additional shock resistance.

- The solid wood is an ageless classic; shields made of noble wood can serve for decades. However, the choice in favor of natural wood should be made only if there is absolute confidence in the manufacturer’s conscientiousness, otherwise there is a great risk of warping and cracking. The main drawback of wood countertops is the tendency to absorb food coloring, stains from which are almost impossible to remove..

- Polymer concrete is the so-called artificial stone, which has already been written about. The most popular material today for obvious reasons: it forms a seamless surface of an unlimited area, the sink forms a single whole with the countertop, traces of wear are removed by simple grinding. Unlike postforming or wood, polymer concrete can withstand heating up to 200-230 ° C and is absolutely not afraid of water.

It is important to know: the operational properties of artificial stone countertops depend on the quality and type of raw materials, as well as on compliance with the manufacturing technology. Therefore, you can buy such material only with a guarantee of at least 2-3 years..

- Natural stone – can be represented by a massive board up to 60 mm thick or overlays on the surface and end of the chipboard. Unlike artificial stone, granite, marble or quartzite are more noble materials, but they must have a conclusion on radiation safety. In addition, some rocks are capable of absorbing dyes..

- Stainless steel is a material resistant to any kind of impact. It is used mainly in professional kitchens, but can be used with the same success in everyday life. Two disadvantages: low prevalence and limited variability of kitchen design.

How not to spend extra money

The worktop makes up an impressive part of the kitchen budget: its cost, depending on the material and configuration, can be up to 50% of the total amount. If there is no shortage of funds, it is better to immediately purchase a quality product made of stone or expensive postforming.

A more economical option is to first buy an inexpensive laminated chipboard worktop, use it for a while, and then use it as an insert for a new artificial stone worktop. True, in this case there will be no opportunity to move the sink, but it can be mirrored along one or two axes.

How to take measurements

To ensure that the countertop fits exactly into the kitchen environment, it is made according to individual measurements. There are three installation options and on each of them the specifics of the measurements may differ:

- The table top is ordered after the casings and apron trim are installed. In such cases, it is required to measure with high accuracy the linear distances along each line of abutment to the walls. Angles are usually not measured; instead, templates are assembled from the rails in place. High accuracy of measurements is very important, it allows you to achieve the minimum size of the gaps, respectively, it will turn out to close the junction with a thin neat plinth.

- Measurement after installation of the enclosures and before facing. In such cases, the worktop can be oriented parallel to the longest wall, with gaps of up to 10 mm allowed. After laying the tiles, they will be completely covered, often in such cases you can not install the plinth at all or get by with the thinnest PVC glazing bead.

- At the stage of kitchen design and before finishing. This is the most difficult option, but this is the only way the kitchen will be ready for use immediately after installing the enclosures. It is necessary to take into account in advance the thickness of the tiles and glue, the tolerance for the curvature of the cladding and the size of the deformation gaps, depending on the material of the walls. Recently, more and more often they are abandoning the tiled apron in favor of glass or plastic panels, which allows for a better fit..

Angle templates and linear distances in millimeters are transferred to production. The depth of the countertop must be measured so that its edge is flush with the handles of the facades of the lower tier. If the fronts have push openers or cut-in handles, the projection of the worktop should be 35–40 mm. Cutouts for the sink and hob are marked according to the instructions for a specific product and taking into account the location of the cabinet sections of the kitchen.

The countertop is measured as if it were a solid slab, regardless of the complexity of the configuration. If, for the convenience of delivery and installation, it is advisable to divide the tabletop into fragments, the technologist will do this independently, taking into account all technological tolerances.

Installation of postforming and wooden countertops

Worktops made of wood and laminated chipboard are the only type of products, parts of which are assembled using mechanical ties and H-shaped joining profiles. The cut where the chipboard is exposed is the most vulnerable spot, it should be carefully sealed with silicone or non-hardening mastic.

There are two options for postforming assembly:

- The simplest: from below to the table top along the entire length of the joint, a plate made of MDF or dense solid wood is screwed. In it, oblique holes are drilled in the direction from the joint at an angle of 30–45 °. At the points of the fasteners, starting holes are drilled, the diameter of which is equal to the thickness of the self-tapping rod, excluding the thread. To eliminate the shift of the ends, plastic dowels are hammered into them with a step of 20 cm. Self-tapping screws twisted obliquely securely tighten the tabletop and allow squeezing out the remnants of the sealant.

- With the help of ties: from the seamy side of the tabletop, a Forstner drill is used to make selections for the screw mechanisms, then, according to the installation dimensions, a groove or a hole for a hairpin is drilled at the end. If the thickness of the table top is not enough, overhead bars are screwed along the joint line with a small indent.

Quite often, you have to join L-shaped tabletops, the joint line is 15–20 cm from the corner, for which a special shape is cut. The part that is adjacent to the cut edge is trimmed with a copy cutter according to the template. At the leading edge, you need to make a small oblique cut, which is equal to the width of the front chamfer or fillet. From the reverse part, a wash of a similar shape is made, the excess material is first cut off with a jigsaw with a tolerance of 1–2 mm. Flexible PVC H-profile is used for joining. Some types of connectors can be installed flush with the surface, for which you need to remove small chamfers at an appropriate angle.

Docking of wooden countertops can be done using the described methods, but more often they use joinery joints on glue and lamellas. To do this, one or two slots are made at the abutting ends with a milling cutter, into which thin hardwood strips are inserted. To achieve the minimum thickness of the glue line, the tabletops must be squeezed; for this, sling straps with a ratchet tension mechanism are suitable. To maintain a uniform plane, after tightening and removing the remaining glue, the joint on both sides is clamped on clamps between two flat linings.

Installing an assembled and one-piece worktop

Countertops made of natural and artificial stone, as well as stainless steel, can be assembled in production or on site. The technologies that are used for this are not available to the average person. Nevertheless, in the end, as in the postforming assembly, a solid plate of complex shape is formed, which must be installed and fixed to the walls of the lower tier body..

Installation is done in two stages. First, the tabletop is positioned to ensure the required gap size, then it is fixed at 1-2 points to each section on ordinary furniture corners. The main fasteners are located on the double walls between the sections. On both sides, metal corners are installed, which are pulled together through the walls of the case with screws or pins. The corners should be installed with a gap of 1-1.5 mm from the back surface of the table top.

After that, the centers of the attachment points are marked, the tabletop is turned over and blind holes are drilled for the screwdrivers. The mortise nuts are screwed into quick-drying glue, then the tabletop is turned back and fixed to the housings. When installing the sink and hob, it may be necessary to remove and turn the stove again, but the strength of the threaded fasteners will not deteriorate from this..

What are the main factors to consider when choosing a kitchen worktop? Are there different materials available that offer durability and style? How do I determine the suitable measurements for my worktop? Could you provide some insights on the manufacturing process and the suggested installation method?