Recommendation points

- Briefly about the design and operation of MMA inverters

- Package and delivery form

- What’s inside the block: differences in filling

- Cores, holder, weight

- Dimensions, ergonomics, controls

- Summary and recommended parameters

Today we want to share with you the rules for choosing an inverter for training in welding, as well as for everyday tasks in the country or in a private house. After all, the development of electronics made it possible to make welding equipment affordable, both in cost and in terms of ease of use by a simple man in the street.

Briefly about the design and operation of MMA inverters

Unlike the previously widespread transformers and rectifiers, inverters use a strictly electronic principle of current conversion. The output is the shape of the curve that is best suited for welding with coated electrodes – an almost pure meander (pulsating “constant”) with a variable frequency.

In this case, the frequency of the meander and the stability of voltage levels are almost independent of the parameters and fluctuations in the supply network. This is achieved due to the operation of high-frequency power transistors controlled by microelectronics. It can be either ordinary integrated circuits (PWM drivers), which generate a signal of a certain type, or firmware microcontrollers.

The main work is performed by two elements (sections) of the power circuit. A set of IGBT transistors sets the required level of current at the output terminals of the inverter. The unit of thyristor switches (BTK) generates a pulsation of the welding current with the required frequency. Depending on the current operating mode, the frequency and current at the output can instantly change for better maintenance of the arc.

Package and delivery form

It seems strange, but when choosing a welding inverter for household tasks, the first thing to pay attention to is not at all the contents of the main unit. It is much more important to determine the list of equipment with the most complete and meaningful delivery set, and then, among the selected options, choose the best in technical terms.

This is because most inverters for home and amateur use are of a typical design and rarely have outstanding differences. But the presence of a case, for example, is very indicative, such an inverter is much more convenient to store, and you should not even think about transportation without a convenient box.

The package should include useful things and exclude useless ones. Inverters are in priority, supplied with passport documentation containing the circuit and electrical diagrams of the device, a repair manual and a detailed description of the operating modes. Also, if possible, the kit should include replaceable consumable parts, such as fuses or holder pads. Naturally, the equipment must be guaranteed for at least a year.

But all sorts of little things like shields and brushes in fact are completely useless. Due to the “disability”, these products can be thrown away on the very first day after purchase. Much better if the seller supplies the inverter with a small promotional gift, such as a pair of welding gloves.

What’s inside the block: differences in filling

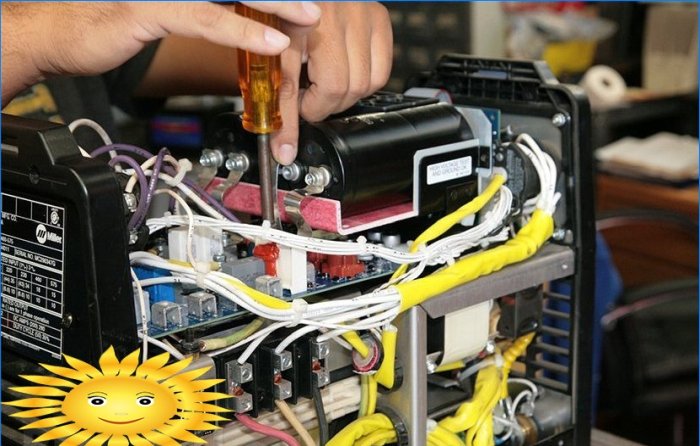

Few novice welders can boast of extensive knowledge in circuitry, and therefore the inverter for them remains something of a black box. But the seller of the details of the device of the welding machine must know and be able to describe the strengths.

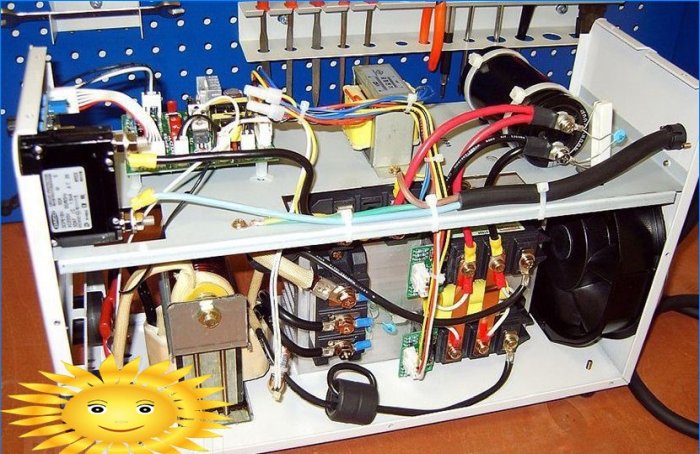

The most important difference lies in the form factor of the power electronic components. These can be either separate transistors and thyristor switches, or they can be combined into one module with a common heat sink. It is impossible to say with certainty which is better. From the point of view of maintainability, individual components are more profitable, at the same time, high-quality modules in a single package spread less interference to the rest of the electronics and work better in a parallel bridge scheme, where the variation in the parameters of semiconductor components has a detrimental effect on the entire assembly. In any case, the radiators of these components should be as massive as possible and with as many fins as possible..

The operation of the inverter can be controlled either by integrated circuits, where signal shaping algorithms are implemented at the “iron” level, or by programmable MCUs. In the latter case, the inverter can have a wider range of protections: against sticking of the electrode, overheating, overload, as well as functions of cold start, crater welding, automatic adjustment of the arc intensity depending on the length, and others. Such a set of “goodies” is definitely good, but in some devices the issue of noise immunity of a sensitive controller is not well thought out, despite the fact that the control and signal conditioning units are located in one rather compact case.

The presence of an extended range of protections and other functions is also possible with control on non-programmable controllers. Such a device scheme is implemented, for example, in Kemppi inverters. Not every manufacturer decides on the production of specialized ICs, but the presence of such indicates an increased level of reliability. The price of such inverters is appropriate. On the other hand, circuits based on more common components will require less investment in case of possible breakdown..

About 90% of modern electronic components are manufactured in China. For this reason, the statement about a purely Japanese or American filling of an inverter costing less than 30,000 rubles. looks at least ridiculous. On the other hand, even branches of such well-known companies as Texas Instruments or Toshiba with a production base in China produce products that are much more reliable than cheap Chinese no-name components..

Cores, holder, weight

Failure of the inverter unit itself is the most serious, but at the same time one of the rarest types of malfunctions. The cores burn out, the holder breaks and the mass holder jaws melt more often..

It is optimal if the bushings and sockets on the cable connections are 12.5 mm in size. The difference with the more common 9 mm connectors in real work is very significant, plus a complete set with collapsible plugs is desirable, because in this place the cables burn out quite often.

The standard cross-section of most of the welding inverters is 16 mm2, length about 2–2.5 meters. The section actually turns out to be only declared, in reality it is slightly higher than 10 mm2. The situation is aggravated by the low quality of the copper alloy, which is why the vein is constantly heated. Again, if you have collapsible connectors, changing the cores to better ones will not be a problem. However, their length cannot be increased dimensionlessly: the majority of cheap inverters with a core length of more than 4-5 meters begin to noticeably fail when igniting and maintaining the arc, or do not give a completely correct value of the current.

The earth clamp and electrode holder are almost never of decent quality. It is better to replace them immediately after purchase in order not to waste extra nerves: a holder with a powerful spring and universal jaws and a screw clamp for ground. In any case, buy a spare holder and clip together with the device – these parts break especially often.

Dimensions, ergonomics, controls

Modern budget inverters are highly compact, which is not always at hand. Due to the stuffing that is too tightly knocked down, there may be difficulty in blowing heat sinks and the influence of noise from the power section on the control.

The optimal dimensions of the block are 150x200x300 mm (WxHxD). A smaller case may have the problems described above, a larger one will simply be inconvenient to transport. The average weight of the inverter is about 4.5–5 kg. A heavier inverter can have either more massive heat sinks or a thicker steel case. If you do not plan to work at a height or on weight, then massiveness is preferable both from the point of view of less sensitivity to shocks and falls, and in terms of stability – a heavy inverter is elementarily more difficult to overturn by hooking a cable loop.

For the case, the optimal degree of protection is IP32, which is quite rare due to the difficulties in organizing airflow. Much more often, the cases are protected by IP21, so the inverter remains sensitive to metal dust, for example, if a grinder is working next to it.

Having a handle and a shoulder strap is definitely useful. In addition, pay attention to the rigidity of the rotation of the adjustment potentiometer – too soft can accidentally get lost when untangling the veins and other careless movements. The presence of a digital indicator, which indicates the actual value of the current, is also encouraged, especially if it is planned to conduct “jewelry” welding. The power button must have a built-in fuse and overvoltage filter.

Summary and recommended parameters

As already mentioned, most inverters are of a typical design, and small differences in architecture do not bode well. The main difference lies in the current limits for the power electronics components, which determine the operating current range of the apparatus. For confident welding with a “four”, 140 A is enough, a 5 mm electrode can be welded at 180 A, and inverters over 200 A cut quite well with an electric arc. If the mains voltage is not high enough, the maximum welding current is also reduced.

A significant current range can be compensated for by a greatly reduced turn-on duration, since all the same cheap radio components are inside. In operation, the most optimal is an inverter capable of switching on at 30-40% at maximum current. For home small-scale production (forging, gates), it is desirable to have a duty cycle of about 50-55% at maximum current.

Do not forget that the welding inverter is nothing more than a switching power supply, therefore, its efficiency is of key importance. 80% is considered the golden mean in this regard, the corresponding amendment must be taken when organizing the supply network.

To summarize: for home use, inverters costing 6000-9000 with a capacity of about 6-7 kW and a single-phase connection are optimal. Similar products of very good quality are represented by the trade marks “Resanta”, VOLTA, “Svarog” and similar domestic and Chinese manufacturers of devices according to import schemes. Tesla or Aurora products have a slightly higher quality and reliability, but the price tag of these devices is corresponding.

I’m looking for recommendations: Which welding inverter would be the best option for home and garden use? I want something reliable and versatile that can handle different welding tasks, but also be portable and convenient for DIY projects. Any suggestions or personal experiences that can help me make an informed decision? Thanks in advance!

Can anyone recommend a specific welding inverter that is suitable for both home and garden use? I am looking for one that is reliable, easy to operate, and can handle different types of welding projects. Any suggestions or personal experiences with specific models would be greatly appreciated! Thank you.