Recommendation points

- What are the main disadvantages of porous ceramics

- Varieties of material

- Purpose of using warm ceramics

- Features of the masonry process

- Elimination of cold bridges and airflow

Porous ceramic blocks cause a lot of controversy today, although most of the conclusions about their practical unsuitability are associated with installation errors or inappropriate use. To build really reliable buildings from PKB, you need to get to know them really closely.

What are the main disadvantages of porous ceramics

Criticism of warm ceramics or PCB is not devoid of a constructive component. However, most of the negative experience of use is associated with non-compliance with construction technology. Basically, claims are made about the bearing capacity, the tendency to lose thermal insulation characteristics after laying and the lack of reliability of the surface mounting.

Basically, such difficulties are encountered when trying to combine various technologies with the expectation of their synergy, but warm ceramics is a completely original material that does not accept an innovative approach very well, but, on the contrary, requires strict adherence to instructions.

Of the real shortcomings, one can single out the impossibility of building buildings above two floors without significantly increasing the thickness of the walls. Yes, in the ratio of the bearing capacity to its own weight, the PCB material is quite profitable, but with a wall thickness of more than 60 cm, the heat-saving characteristics do not increase so significantly, and it makes sense to pay attention to the construction technology on a reinforced concrete frame.

To build a good house from porous ceramics, you should adhere to a number of requirements regarding the choice of a suitable type of block according to the purpose, as well as carry out the masonry in strict accordance with the manufacturer’s recommendations.

Varieties of material

First of all, one should learn to distinguish between the concepts of warm ceramics and porous blocks. Despite the external similarity, these building materials perform a double function as part of the masonry of the enclosing walls. As a rule, warm ceramics are not involved in the construction of a building, but they serve as external thermal insulation. At the same time, the outer layer also perceives indirect loads, adding monolithic strength to the masonry.

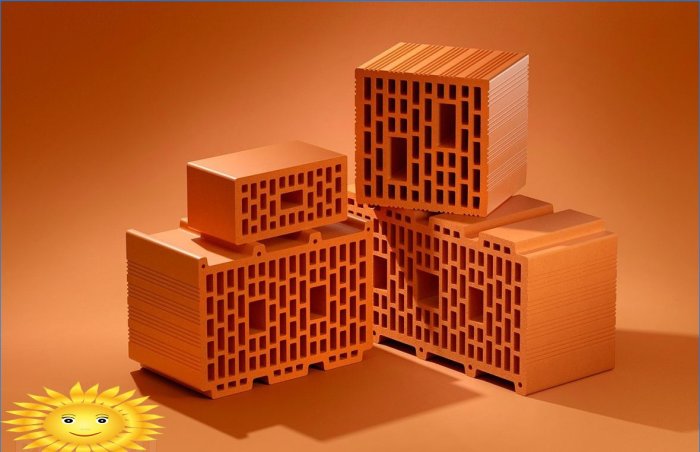

The direct bearing function is assigned either to porous building blocks or to the frame structure. In the latter case, “cold” PCBs, as a rule, are not used, preferring lighter, warm ceramics. It is very simple to distinguish building blocks from insulation blocks – in terms of bulk density. The walls of the latter can be up to 2–3 times thinner, but the pores are commensurately smaller and have a honeycomb structure for lengthening cold bridges. The difference in the weight of blocks of the same size is about 25-30%, you can only make a mistake out of ignorance..

Warm ceramics do not have the required compressive strength, the control grade is limited to M150, that is, the value exclusively necessary to maintain the self-supporting function. For building blocks, the ultimate destructive effect can correspond to the M300 brand, which seems to be a quite suitable material for two-story construction. In fact, shell rock blocks are actively used even to support precast concrete floors, while its strength grade is much lower and in general it is not such a technological material. In the simplest approximation, two varieties of PCB can be compared with gray and yellow shell rock: although the strength classes of materials are somewhat different, the general concept of use is the same.

Purpose of using warm ceramics

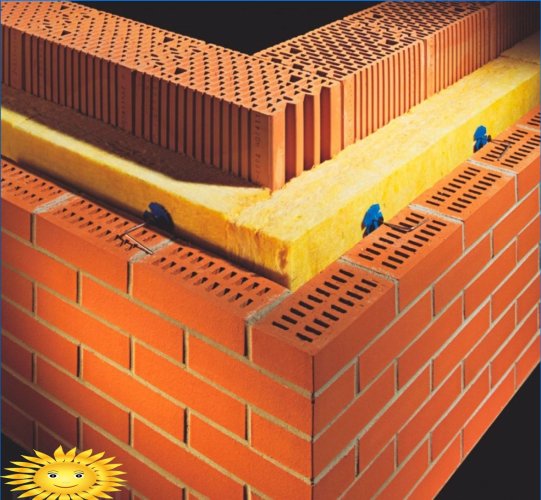

The construction of a warm house from ceramic blocks is an attempt to reduce the cost of insulation by significantly reducing the thermal conductivity of the capital structure. It must be understood that without the elimination of the main cold bridges, the advantages of the material will not be fully expressed, from which there is an opinion about the inexpediency of fiddling with complex masonry technology.

The main use of warm ceramics is buildings with heat losses not exceeding 50-70 kW * h / m2, that is, with reduced power consumption. In this context, this implies the installation of high-quality double-glazed windows, insulation of the basement, optimization of ventilation and equipment of a warm attic. In such construction, warm ceramics is a real find: the supporting layer or a significant part of it does not form zones of active heat outflow or reduce it to a minimum..

Another advantage is the ability to fix an almost unlimited amount of insulation between layers of masonry. However, it is worth remembering that the sensitivity of the heat insulator to moisture in this case is absolutely unacceptable. The dew point, as a rule, is located directly under the layer of warm cladding and therefore there is always a space for ventilation.

In order for the condensation boundary to be exactly in the blown layer, the thickness of the layers with different thermal conductivity is varied by intermediate construction of Glaser diagrams, as a way to determine the saturation point. The calculation takes into account that ceramics has a limited ability to pass steam, but, unfortunately, it cannot be used as the main vapor barrier, because the blocks do not have a sealing adhesive bond on all faces.

So, to summarize: for buildings with a claim for highly efficient heat saving, PCBs are one of the best technical solutions. This material is also quite suitable for creating durable cladding with low heat transfer. But attempts to impose on the same grade of PCB requirements for high strength and at the same time high resistance to heat transfer will definitely not lead to success..

Features of the masonry process

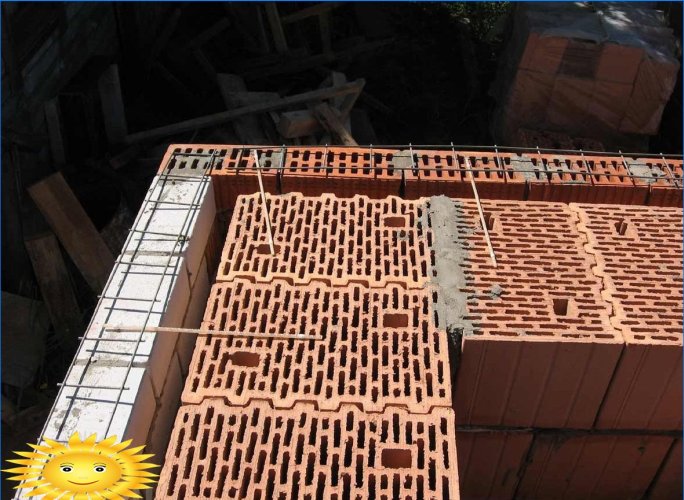

You can often find complaints that during laying, the solution flows into the pores and significantly increases the thermal conductivity of the blocks. Subject to the masonry technology, such a disadvantage is not expressed: each row is covered with a mesh that prevents the binder from draining. The latter is used a minimum amount: often blocks (polished) are simply dipped with the bottom end in a solution of a liquid consistency, which contains adhesive additives. These two innovations are an integral part of the technology..

Further on the differentiation of functions. First, a supporting layer is laid out from the PCB and overlappings are mounted on it. The upper row of masonry is used as a support for the formwork, covered with waterproofing along the bottom and walls. In this case, a reinforced concrete crown is used as a Mauerlat, it is also an armored belt. Porous ceramic or foam concrete trays can also participate in its device, it remains only to carefully seal the joints between them.

Insulating cladding is performed along the outer border of the foundation, sometimes with a small ledge of 1-2 cells. There are several options for dressing when organizing only one ventilation layer:

- Joint laying of two layers, covering each row with a single strip of mesh.

- Laying of special polymer anchors for dressing.

When located between the cladding and the supporting layer of additional thermal insulation, it is attached to the internal blocks with an adhesive bond and subsequently bonded with a solution to the blocks of the “warm” lining. The latter is performed continuously from the foundation to the Mauerlat, covering the ends of the floors and the armored belt. Fastening of windows and doors is carried out in the outer part of the wall, but not closer than 2/3 of the thickness of the insulation blocks to their outer surface. With significant wind loads, it is recommended to lay solid elements, both along the vertical parts of the opening and at its base..

Elimination of cold bridges and airflow

In general, the presence of full-bodied mortgages is the main problem of buildings made of porous ceramics. It is quite difficult to perform critical installation without them, and cold leaks in these zones are very pronounced. In this case, the porous ceramics adjacent to the cold bridges acts as a radiator with many fins and actively removes heat..

The opposite effect is obtained: in building blocks this property is less pronounced due to the smaller surface area, therefore the dividing bridge, which prevents the outflow of heat, must be mounted in this layer. Thus, lintels of openings and installation embeds are actually made by two different products without connecting reinforcement, with the exception of polymer anchors..

For insulation, both non-compressible slab materials such as EPS and special products, such as trays, can be used. There can be two dividing jumpers, usually the mortgages for fastening windows are arranged in this way.

Another disadvantage of the PCB is the lack of an adhesive bond on vertical seams. Despite the increased path of the convection flow by the groove, the gas exchange is quite strong, especially at high wind pressure. The problem does not stand as such when placing additional insulation between the layers of the PCB with hermetic sealing of the seams. In other cases, it is required to fill the joints with polyurethane foam from the inside. Its consumption is low, but the use of an extractor with an adjustable dispenser and a thin nozzle is required. The permeability of the outer layer is usually not eliminated, due to which the problem with low-activity condensation is completely solved.

I’m curious to know if a house made of porous ceramic blocks or warm ceramic materials offers any specific advantages or disadvantages compared to traditional construction methods. How do these materials affect the insulation, durability, and overall energy efficiency of the house? Additionally, what are some key factors to consider when building or buying a house using these unconventional ceramic materials?