Recommendation points

- The origin of the facade plaster

- What can facade plaster

- How to choose a protective facade coating

- Decorative plastering

- Basic tools and auxiliary materials

- Place to work

- Weather

- Once again about surface preparation

- Preparation and rules for working with solutions

- Applying mortar to the wall

- General recommendations for the technique of working with facade plasters

In this article we will consider the issues of choosing the right protective and decorative facade coating. Let’s figure out what properties of facade plasters make them indispensable in certain cases. And, of course, we will discuss the technique of using such specific building materials..

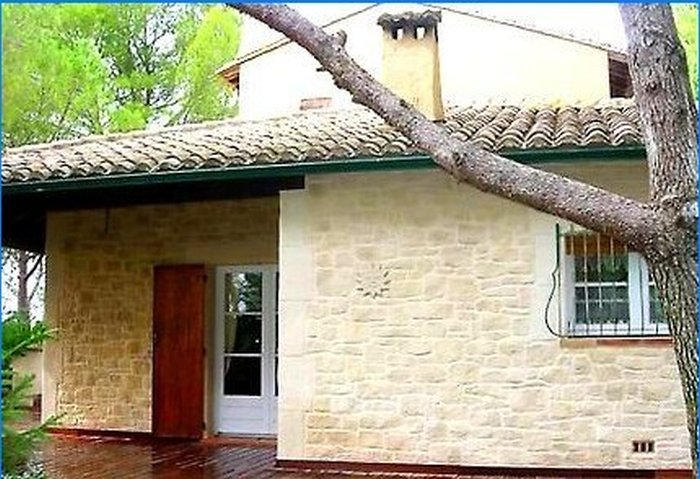

The origin of the facade plaster

Europe has long learned how to effectively save energy resources and take care of improving the environmental situation, which has led to the adoption of stringent standards for thermal insulation of buildings. It is precisely as a protective and decorative element of facade insulation systems using the bonded insulation method, which we talked about in the previous article “Do-it-yourself facade insulation with foam plastic”, that innovative technologies of thin-layer facade plaster came to us. As you know, in Russia for a long time there was an opinion that “it is not necessary to insulate, the main thing is that the walls are thicker and beautiful”, so here you can often find decorative facade plaster on a bare bearing base. But time passes, and Russian developers began to understand a lot about energy saving, plasters for facade finishing have firmly established themselves on construction sites in the country, they began to be used exactly for their intended purpose – as a system material that protects thermal insulation boards.

What can facade plaster

Facade plaster is a very specific building material, which largely determines the exterior, “face” of the entire home, its originality and identity. Even two adjacent houses, built according to the same standard design, will become unlike each other if their facades are finished using different techniques and plastering compounds. And the point here is not so much in color solutions, although there can be an unlimited number of them, which cannot but please designers and developers, but rather in a subtle drawing, as well as a pronounced unique texture.

The purely decorative purpose of facade plasters does not cause doubts among many people, although their main function is to protect load-bearing structures and elements, as well as functional layers, which is external insulation by the method of bonded insulation. And, in fact, there is something to protect. First of all, it is atmospheric moisture, and secondly, etc. – these are mechanical influences, solar ultraviolet light, aggressive chemistry of industrial emissions. It is believed that, despite the relatively thin finishing layers, the facade plaster serves as an additional insulating and sound-insulating layer, is an excellent fire protection of a building lined with expanded polystyrene.

An important parameter of protective finishing facade coatings is their vapor permeability and, at the same time, high resistance to diffusion from outside..

Thin-layer facade coatings well restrain the daily temperature expansion of the outermost wall materials, these indicators are incomparably better than those of the “smooth” cake: “cement-sand plaster – mesh – facade putty – facade paint”. Protective facade plaster, together with reinforcement, provides a reliable cocoon with a thickness of about 7-9 mm, and putties are intended for thinner layers.

Facade plasters can hide, to a certain extent, local irregularities in the walls. Due to the texture, it is possible to avoid the most difficult type of painting work – puttying “for painting”, especially under aggravating circumstances, such as large areas and a powerful source of constantly moving side light, which is the sun. Tinted plasters do not need to be painted at all.

It should be noted that the properties of plasters are similar to those of facade paints made on the basis of the same binders, only they are more pronounced due to the thickness of the working coating. Selection and dosage of polymer components provide modern facade plasters with good consumer characteristics, including: elasticity, hiding power, outstanding adhesion, including to non-mineral substrates (wood, steel …), simplicity and ease of preparation and application, long shelf life, clarity recipes, matching color palettes, sometimes self-cleaning ability.

How to choose a protective facade coating

With the choice of plaster, which you will use on the facade of the house, in fact, the work on its application begins, because not all of them are universal, some of them require special preparation of the base, special primers, etc..

At the moment, it is not difficult to find a decorative and protective facade coating that is ideal for specific purposes. The market is saturated with plasters for facade elements for various purposes, with certain properties and for every budget. Imported and noticeably improved domestic manufacturers are waging an uncompromising competition. More and more often you can find such services as: complex supplies of materials, free tinting directly at the object or in the studio, organization of training seminars and master classes. Production technologies are constantly being improved, the cost is decreasing, the assortment is expanding. Plastering compounds are sold in the form of dry mixes or ready-to-use polymer pastes, pigmented in the mass or requiring subsequent painting. They differ in the type of binder, texture, size and type of granular filler. Let’s look at the main types of facade plasters and figure out how to choose the right one.

Mineral decorative plastersfor facades they are made on the basis of cement, they are also called “polymer-cement”. They are supplied, as a rule, in the form of a powdery ready-made dry mixture, which must be diluted with water immediately before starting work and stirred to the desired consistency using a low-speed power tool. They are applied on the main planes of mineral substrates, pre-treated with fixing primers with quartz sand. Polymer-cement plasters have very serious strength and abrasion resistance, they protect well from moisture, and also have good vapor permeability. Their only drawback can be considered a small elasticity, which causes a weak resistance to mechanical stress and the appearance of microcracking. The undoubted advantage of this type of plasters is their affordable price, although there are VIP options with marble chips, glitters, etc. Mineral compositions are absolutely non-flammable, therefore they are widely used on facades insulated with expanded polystyrene. Usually, such a dry plaster has a white color, it is almost impossible to tint it in bulk, therefore, after applying the finishing layer, painting will be required. It is quite simple to work with polymer-cement plasters, even a novice master can do it.

Acrylic plasters belong to the class of synthetic materials, they are based on high molecular weight polymers – acrylic resins. They are sold as a ready-to-use, water-dispersible formulation. Acrylic plasters have good adhesion to mineral materials, they are very elastic and resistant to deformation of the substrate. Acrylic resins provide very low water absorption of the finished coating; therefore, such plasters are recommended for use in conditions of strong precipitation. Among the disadvantages should be noted the flammability of acrylic-based plasters. The main nuance is low vapor permeability, as well as difficult diffusion for carbon dioxide, as a result, acrylic plasters are not allowed to be used on facades insulated with mineral wool. It turns out that moisture does not pass through the acrylic film and settles on the insulation plates, sharply reducing their thermal insulation properties.

Silicate plasters produced on the basis of potash “liquid” glass. Such coatings are very hydrophobic and have excellent vapor permeability and are applied over mineral wool. Facades finished with silicate plaster do not crack due to the elasticity of the topcoat, which is also antistatic, therefore does not attract dust and is easy to clean. They are presented in finished form, before applying you just need to stir the composition. The disadvantages of silicate plasters include the need for quick application, and, therefore, the craftsmen have some experience and skill. The color range of silicate plasters is somewhat limited; it is necessary to apply special silicate primers under them.

Silicone (siloxane) plasters they are based on silicone resins, which give the finishing facade coating excellent characteristics. In fact, these are the most advanced and technologically advanced plasters, they are very flexible, waterproof, and have the longest service life. High vapor permeability and excellent adhesion allow the use of such plasters on any substrates. Silicone coatings are excellently washed and even self-cleaning under the influence of precipitation, because they were developed specifically for megacities with a problematic atmosphere. They can be used without any problems near dusty roads and industrial plants. Silicone plasters are tinted in mass, have good hiding power and are easily applied to the base. Perhaps the only drawback of silicone facade plaster is the rather high cost. It is imperative to use silicone primers.

An important criterion for choosing facade plaster is its appearance, which is largely determined by the texture of the finished coating. It is very important here what type and size of granular filler is used in the manufacture of protective and decorative composition..

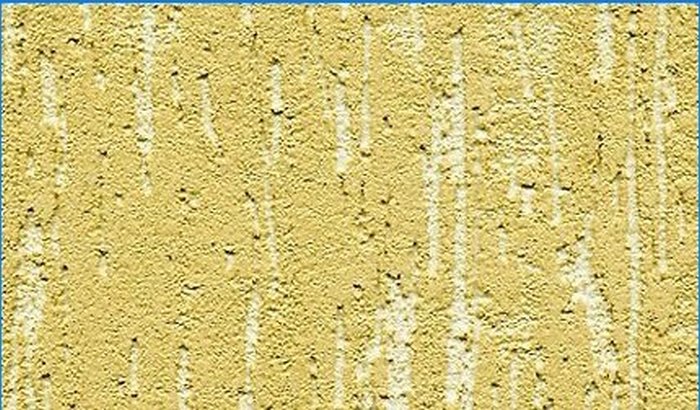

The most widespread texture of facade coatings is bark beetle or Munich. In the filler, such facade plasters have a certain number of single grains, pebbles ranging in size from 1 to 4 mm. Rubbing an almost fresh solution, the master traces the coating with rolling particles.

Depending on the direction of movement of the plastic grater and the manner of work of a particular person, various effects are obtained – horizontal, vertical, circular, chaotic. The grain diameter makes the texture either softer or more expressive. By painting an already tinted bark beetle with a short-haired roller, you can get an interesting two-tone pattern that emphasizes the texture.

The “pebble” texture is obtained by using in the plaster many grains of the same size, which when grouting are compacted and acquire the texture of small densely packed pebbles. It is also called “under the pebble”, fleece, lamb, goose bumps …

The binder of some plasters is transparent resins. They contain a placeholder of a specific color or combination of colors. This can be quartz sand, small stones, marble chips, and other similar materials. These compounds are applied and smoothed with metal trowels, after which the plaster hardens, forming a “glass” colored coating. This texture is called “mosaic”, it is often used on basements of buildings, balustrades and other complex elements..

Many firms offer structural plaster for the facade, the texture of which is modeled using various auxiliary tools, such as: sponges, structural rollers, brushes, scrapers, trowels, trowels, etc. The appearance of these coatings can be very diverse, limited only by the imagination and skill of the performer. They have a relatively fine filling grain fraction and are very tacky to the substrate, which allows them to be sprayed on. Therefore, structural plasters are indispensable for finishing curved and geometrically complex surfaces..

Interesting effects are achieved by combining different textures on one facade. For example, the main walls are finished with textured plaster with a coarse fraction, about 3 mm, and protruding decorative elements, slopes – with a smoother coating, for example, with a grain of 1 – 1.5 mm.

Decorative plastering

The technology of using various types of plasters for facade decoration has a lot in common. Knowing the basic principles of such work, some practical points, you can quite successfully independently apply a protective and decorative coating to the facade, not resort to the services of highly paid specialists.

Basic tools and auxiliary materials

So, we have already purchased the plaster mix and are ready to start plastering work. To decorate the facade manually, we need a small set of special tools.

The application of plaster to the base, as a rule, is done with a stainless steel grater with rounded corners, some craftsmen prefer to work with spatulas, collecting the mixture from a plaster falcon. It is convenient to apply the finished composition on a grater with a metal trowel. For hard-to-reach areas, narrow spatulas of various shapes may be needed. To give the plaster layer the necessary texture and seal the filler, plastic graters are used. We have already talked about tools for imparting texture to structural plasters..

Priming of surfaces is usually done with maklavits, with some types of primers it is quite possible to cope with a filamentous roller. If you take a wooden lath 1.5-2 meters long, with a cross-section of about 40×30, make a cut from the end at an angle of 45 °, and attach a maklavitsa brush to it with long screws, it will be very convenient to prime large surfaces, which are usually the facades of buildings. By the way, brushes with broken handles get a second life in this way. But the roller is more convenient to put on a telescopic painting rod. For difficult places, flat, flute, brushes of different sizes are useful.

To prepare the solution, you will need to have at least a 20-liter plastic bucket, in which you can stir 25 kilograms of material. Another container, possibly of a smaller volume, should be kept with clean water at the place of preparation of the solution, in it after each batch you need to rinse the whisk, so it will always be clean. In order for the plastering composition to strictly comply with the recipe, you will need a water meter.

We will mix a dry mixture ready to use or mixed with water with a relatively powerful electric drill with a frame or auger nozzle. It is important that it is low-speed – about 400-800 rpm. Do not use a rotary hammer with an adapter chuck for these purposes, long work in rotation mode will adversely affect the service life of this expensive tool. The best option is to use a special one The best option is to use a special mixer for the preparation of solutions, they are relatively inexpensive and very convenient for this type of work, since they have a long nozzle, reliable side handles, suitable power and speed.

To get really high-quality coverage, it will be necessary to arrange artificial side lighting. A street spotlight with a halogen lamp can be a great source of light. It is worth making a tripod for him from scrap materials or buying a factory one. Prepare an electrical extension cord of the appropriate length.

In order to protect the finished surfaces and various elements of the building from contamination, you should stock up on masking tape and covering material – cardboard, polyethylene.

Place to work

The main thing in facade work is correctly exposed scaffolding and scaffolding. It is very important that the craftsmen have free access to the area of the base, which is planned to be plastered in one working day, as a rule, this is a whole wall from corner to corner.

So that the racks and crossbars of the scaffolding do not interfere with technological processes, they must be at least 20 cm away from the walls, and at least 30 centimeters when applying plaster by spraying. Most experienced specialists prefer to stretch a dense mesh over the scaffolding, which protects the freshly applied solution from direct sunlight, wind, side rain. The scaffold fasteners to the walls must be dismantled and the holes sealed.

Adequate illumination of work surfaces should be provided with electric lamps and spotlights..

We recommend covering windows, doors, roof sheathing, various facade brackets, gas pipes and other elements with masking tape. Also tape the possible lines of separation of texture and colors. Cover the blind area, roof of the porch or bay window with plastic wrap, cardboard.

Carefully prepare the place where the solution will be mixed. It should be a flat area of sufficient area, preferably under a canopy or indoors. It is necessary to lay the floor, cover the walls and various objects located near the wall with foil. It is recommended to make a supply of water and take out the material necessary for one work shift. Sometimes it makes sense to prepare a backup power supply in advance if outages in public networks are possible.

In some cases, in the area of dangerous facade work, for example, scaffolding, it is necessary to restrict the passage of people, and cars parked too close can also interfere. Use alarm tape or temporary fences.

Weather

Facade plastering should be carried out only at a stable above-zero temperature, most manufacturers indicate the interval from +5 to +25 degrees. In summer, many craftsmen prefer to work in the morning and in the evening; they protect the surface from direct rays of the sun with a net. No less serious requirements are put forward for humidity. This is no more than 10% for the base and no more than 80% – the permissible air humidity. Strong wind and rain can also damage the quality of the plaster layer. Don’t skimp on preparing the shelter, check out the weather forecast for tomorrow.

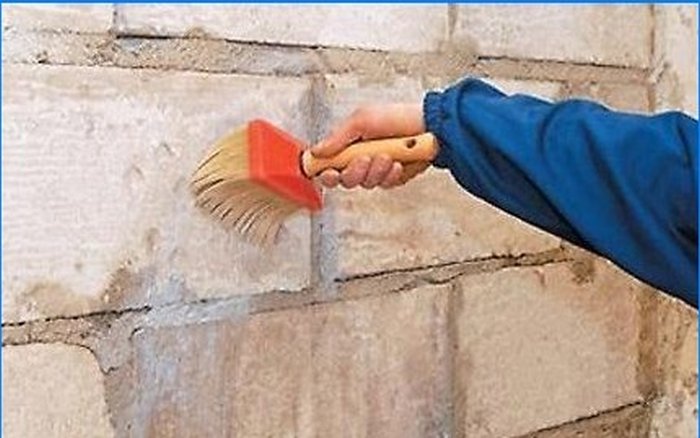

Once again about surface preparation

The wall should be even, the texture of decorative plaster will hide only small errors on the plane, do not forget, our coating is very thin – from 1 to 4 mm. The surface must be of sufficient strength. The coarse grains of the filler should roll with the movements of the grater, but not press into the base. A competently made reinforced layer on top of the insulation will perfectly cope with this task..

When working with any kind of facade plaster, the walls must be primed. Most often, a primer with quartz sand is used, which tightly covers the base, provides excellent adhesion, and due to the rough surface, the plaster is very easy to apply. Depending on the type of binder of polymeric protective and decorative facade coatings, the primers should be similar – silicate, silicone … Sometimes they need to be tinted to the color of the selected finish.

Preparation and rules for working with solutions

Pour the required amount of water into the prepared container, then gradually pour out the dry mixture and mix the solution thoroughly for 1-2 minutes. After that, the plaster should be infused for several minutes, “ripen”, now it needs to be stirred again. The correct mixture is homogeneous without lumps and air bubbles. The time to work with the ready-made composition is limited, do not mix it too much. Do not add water to thickened polymer-cement plasters, just mix them with a drill.

Ready-made synthetic plasters should be simply mixed before use. Keep material buckets closed. When opening, make sure that no dried particles of the composition get into the plaster from the lid. The mixer nozzle must always be clean, rinse it in a special container.

Attention! All plastering compounds must be periodically mixed during operation..

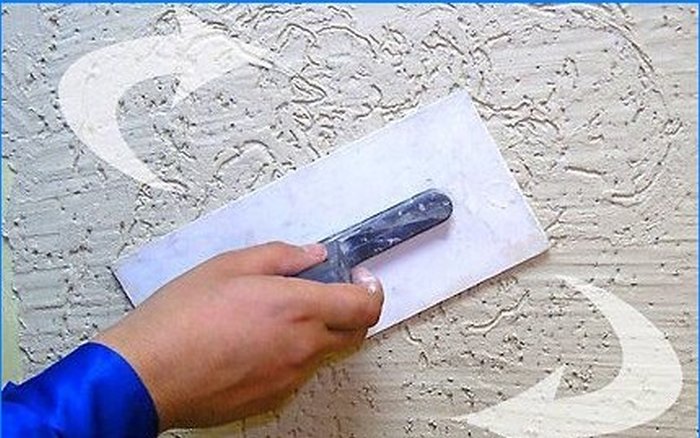

Applying mortar to the wall

We take the plaster from the bucket with a trowel, and already apply the finished solution to the wall with a metal grater or spatula. It is very important that the plaster is applied evenly, without gaps and sagging. The thickness of the layer should be equal to the diameter of the aggregate grain; for this, the mixture is stretched over the surface like a putty until small scratches and grooves appear. The excess solution is collected in a tray and mixed. The tool should be held at an angle of approximately 60 ° with moderate pressure on the base.

While the synthetic plaster is wet, smooth it with a metal trowel, giving the coating the desired texture..

Mineral compositions, for example, with a bark beetle texture, also pass through a wet layer for the first time, practically without pressure, using a plastic platform with rounded corners. Moreover, if the material sticks, this means an excessive layer thickness that needs to be removed. If grooves do not appear on the surface at all, add solution.

The second time the coating is processed after some thickening of the material on the surface, when it stops sticking to a clean dry grater – usually after 10-20 minutes. Now the movements should have a clear direction on which the drawing depends, more pressure must be applied. The main task is to find the golden mean between the smoothness of the coating and the visibility of the furrows. In any case, you need a uniform pattern on the entire wall..

Once you are done with the formation of the texture, you should immediately remove the protective masking tape and remove all sagging near the enclosing structures.

General recommendations for the technique of working with facade plasters

Do not use compositions with different lot numbers on the same wall.

Make trial applications of plaster on small surfaces, work out the amplitude and trajectory of movements, experiment with texture, color. The remains of drywall are perfect for these purposes. Fasten them vertically and do not forget to prime them first.

On the facade, to start work, select a small or subtle wall. This will help you work out the technology painlessly..

It is better to apply the facade plaster at once on the entire wall “from corner to corner”, using the “wet on wet” method. If there is a break, and any joint dries up, it will certainly be visible. You can easily interrupt on the separation of colors and textures, under the pipes of the storm system. In other cases, it is recommended to stick masking tape on the base along the vertical line of the windows, so that the joint is as short as possible, thus separating the border. After that it is necessary to apply plaster, completely form the texture and immediately remove the masking tape.

It is better to plaster large walls with the efforts of two people. At the same time, the ideal option is if one master will apply and level the solution, and another person following will form the finishing texture. They usually start work from the top corner, moving downward in a “ladder”.

Internal and external corners are performed when one of the adjacent planes is already finally ready.

Check the quality of the mortar application using a side light from a spotlight.

Before painting and varnishing, the finished plaster must be treated with a penetrating acrylic or siloxane primer, depending on the type of finishing facade coating.

Adhere to production breaks between operations as specified by material manufacturers. Follow directions for use exactly.

This text intrigued me about the ease of decorative facade plastering. Could you please explain the process and techniques involved in achieving a successful and effortless outcome? Are there any specific tools or materials recommended for beginners in this field?