Recommendation points

- Types of sealants

- Acrylic

- Silicone

- Polyurethane

- Bituminous

- Sealants for threaded connections

- How to choose the right sealant

In the repair, special attention should be paid to the correct selection of materials. One of the most versatile and commonly used is a sealant. What they are, what types there are, where and how they are used, as well as how to choose the right sealant, we will tell in our article.

What is a sealant in the broadest sense of the word? Building material based on polymers, vulcanizing at room temperature, used for gluing, sealing, filling small cracks and gaps, and retaining elastic properties after complete drying. Sealants are sold in tubes and tubes. In the first case, the sealant is squeezed into the place of sealing by hand, in the second – with the help of a special pistol.

Types of sealants

Acrylic

The main component is acrylate resins. After drying, they become low elastic. They have good adhesion to most porous building materials (concrete, brick, wood, etc.). Since they cannot withstand low temperatures (below -20 ° C), they are most often used indoors to seal the seams of doorways and windows, to fill cracks. After complete drying, it can be painted with acrylic paints to match the surface color. They are non-moisture resistant – more environmentally friendly, odorless, but destroyed by the action of water, and moisture resistant – they can withstand the ingress of a small amount of water. In any case, the chemical properties of acrylic sealants do not allow their use in places that are constantly in contact with water..

Silicone

The main component is silicone (at least 45%). Highly elastic even after complete drying. Good adhesion to almost all materials, including non-porous ones: ceramics, glass, aluminum and the like. Water resistant. They are used to seal any seams and joints. Since silicone cannot be dyed on its own, it is available both in transparent and already dyed in various colors. Divided into:

- general purpose silicone sealants – contain at least 45% silicone rubber and at least 45% hydrophobic filler;

- sanitary silicone sealant – it contains antifungal additives that prevent the formation of mold, which often occurs in bathrooms;

- sealant for aquariums – on the one hand, it is not subject to the negative effects of the biological environment of the aquarium, on the other hand, it does not emit any harmful substances itself;

- window sealant – contains additives that prevent mold formation and increase resistance to ultraviolet exposure to sunlight.

Polyurethane

They are made on the basis of polyurethane. High-strength and at the same time elastic properties of such sealants allow using them in any work. The only drawback is the high toxicity until completely dry. Therefore, it is better to use polyurethane sealants for outdoor use and be sure to use personal protective equipment when working..

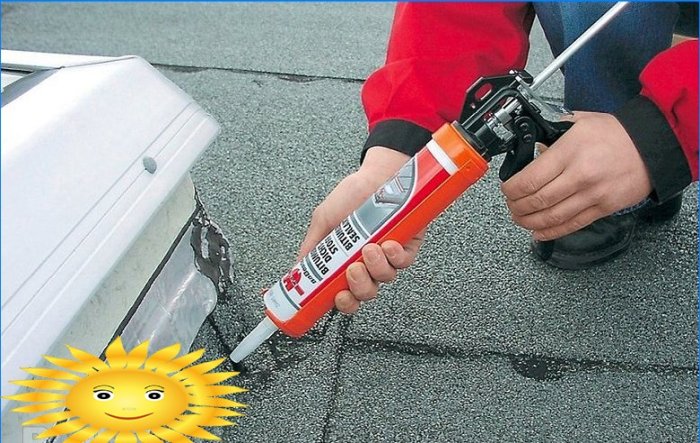

Bituminous

Bitumen based sealants. They are mainly used for roof repairs. They have very good adhesion to any roofing material. Weather and moisture resistant. They are applied only at positive temperatures, but after drying they withstand negative values down to -50 ° С.

Sealants for threaded connections

A separate type of highly specialized sealants. As the name suggests, they are used to seal threads along with sanitary flax, fum tape and similar materials. It should be emphasized that, unlike other types of sealants, which have several areas of application, this one is the most specific. It is used only for threads and, just as important, no other sealant is suitable for these purposes.!

You can also highlight hybrid options for sealants: acrylic-latex, silicone-polymer (MS-polymer), but today, due to the high price, they have not gained much popularity.

How to choose the right sealant

The first thing to decide on is the amount of work. As already mentioned, sealants are available in tubes and tubes. The volume of tubes is in the range from 40 to 150 ml, the price is up to 150 rubles. The volume of the tube is about 250 ml, the price is from 150 rubles. In addition, a sealant of such packaging is used only in conjunction with a special gun, the minimum price of which is 100 rubles. Thus, if the volume of work is small, then it makes sense to buy a sealant in tubes. The total price of a tube and a pistol is at least 250 rubles, which is much higher than the price of a tube, but if you plan to use more than 250 ml of sealant, then it makes sense to spend money on a pistol for tubes. In addition, such a purchase will be justified by the fact that it is used not only for sealants, but also for any other materials in similar packaging (liquid nails, adhesives, etc.), that is, it can still be useful on the farm.

The second is the manufacturer. Generally speaking, you can find sealants from various manufacturers in stores. The most famous: “Moment” (Henkel), Titan, Cerezit, “Bison”. In addition to them, there are a huge number of little-known ones, which it makes no sense to list. The unit cost may vary significantly. What to choose: brand or non-name? The name makes up a large percentage of the price of branded sealants, therefore, buying such a product, you get guaranteed quality, but at the same time, by definition, you overpay. Buying a sealant from an unknown company, you save money, but you risk stumbling upon a poor-quality product. In principle, most often there is practically no difference in the quality of brand and non-name sealants. Therefore, if you have already bought the products of a little-known company, and it suits you, then you can safely use it in the future. If on sale there are only sealants from manufacturers completely unfamiliar to you, then in order to minimize the risk, you should pay attention to two points.

Date of manufacture and expiration date – Keep the sealant as fresh as possible. In this case, the date of manufacture and expiration date should be applied to the body of the tube or tube with indelible paint or squeezed out. If they are trying to sell you a sealant, on which the date and production date are indicated on an adhesive paper sticker, then most likely they want to deceive you and slip an expired product.

The build quality of the case. Even if the sealant is not expired, this does not mean that it is good. Unfortunately, there is no way to look inside the tube before buying, but you can pay attention to the packaging itself, how well it is made. Also, don’t hesitate and sniff the product. The tubes must be completely sealed and therefore must not smell. The smell of ammonia is a sure sign of leaks in the packaging, which means that the product is of poor quality in general. Tubes have a movable piston on the back side – it is he who, like in a syringe, squeezes out the sealant. Therefore, the tubes cannot boast of absolute tightness. Because of this, a weak smell will always be present, but it is a weak, and not a sharp.

The third is the scope. This has already been written above, the most important thing is, if you do not know which sealant is better to use in your particular case, then consult a specialist. Moreover, it makes sense to describe to him exactly the problem that needs to be solved, and he will tell you how and by what means it can be done.

For example, your water pipe is leaking. Most people believe that to repair pipes, it is enough to anoint the outside of the leak with a sealant and that’s it, while completely forgetting that the pressure of water from the inside of the pipe will simply tear off such a patch. The specialist will immediately point out such a nuance and advise either to use a pipe bandage together with a sealant, or suggest some other way to eliminate the leakage, and thereby save you from unnecessary expenses.

In conclusion, a few words about tools and aids for working with sealant.

Pistols.They are manual, pneumatic and electric, depending on how the piston is set in motion. Pneumatic and electric are used by professionals only. For domestic purposes, hand pistols are sufficient. They are skeletal (top) and half-body (bottom) open type. In addition to open-type pistols, there are tubular or closed-type pistols. They are used to work with sealants that do not have individual packaging (tubes). This tool is used for professional purposes only..

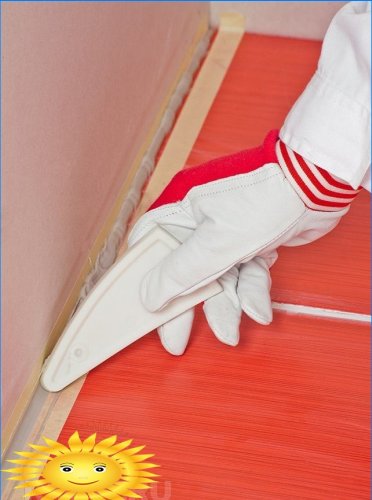

Putty knife.Rubber or plastic spatulas are used to level the applied sealant layer. However, most of the work can be done using only hands. In this case, however, do not forget about individual protection. Disposable rubber gloves are enough for this..

Sealant removers.First, before starting work, it makes sense to glue strips of masking (paper) tape along the lines of applying the sealant. This will make the finished work more accurate and protect surfaces from contamination with excess material. If, nevertheless, the workplace was stained, then there are two ways to remove the sealant from the surfaces:

- Mechanical. The excess is removed with any scraper. In addition to the need to clean the places of contamination, it should be remembered that the sealant is always applied in excess, which is either removed with a finger or a spatula before drying, or cut off with a knife after drying.

- Chemical. Where it is not possible to mechanically clean the sealant, special chemical agents are used, for example, such as Silicon-Entferner, Sili-Kill, Soudal Sealant Remover and the like. They are also great for softening thick layers of cured sealant. Chemicals are only suitable for removing silicone. Acrylic and other sealants can only be removed mechanically.

It should be remembered that a fresh layer of silicone sealant practically does not adhere to an already vulcanized old layer, therefore, in such cases, special attention must be paid to removing traces of dried material..

What factors should one consider when selecting a sealant? Are there specific types of sealants recommended for different applications?

What factors should one consider when selecting a sealant? Are there specific types of sealants for different applications? Any tips on choosing the perfect sealant for a particular project or surface?