Recommendation points

The dimensions of the timber used for the construction of walls are limited by the diameter of the tree. In regions where freezing temperatures in winter sometimes reach -40 ° C, heating costs for such a house significantly increase. Insulating the walls of the house and covering them with clapboard or siding partly solves the problem without detracting from the advantages of wood.

The choice of insulation

The purpose of thermal insulation is to prevent the penetration of cold or warm air. The resistance to heat transfer of materials is mainly due to the presence of a large number of closed pores filled with air. The thermal conductivity of air is very low and amounts to 0.02 W / (m0FROM).

Only air in a standing state does not conduct heat or cold. In the air flow, its thermal conductivity increases. Consequently, the smaller the pores in the material, the lower its thermal conductivity. Also, the thinner the layer of solid between the pores, the lower the heat absorption..

Cellular insulation – expanded polystyrene

In terms of structure, heat insulators of fibrous (glass, eco- or mineral wool) and cellular (polyurethane foam, expanded polystyrene) origin are used to insulate walls from a bar. In shape, taking into account the vertical installation of the material, these can be rolls or plates.

Roll fiber insulation – glass wool

The porous structure of the heat insulator is created:

- foaming the starting material;

- the introduction of gas-forming additives;

- the connection of individual particles or fibers during heating, gluing or other action.

When many insulating materials get wet, their conductivity increases significantly. The indicator characterizing the resistance to heat transfer is 25 times higher for water than for air. That is why most heat insulators need moisture protection..

It is also necessary to take into account such an indicator of thermal insulation material as air permeability, which is important when working with wooden structures. Cellular types of heat insulators, having closed pores in their structure, do not have the ability to let air through, so the wood is not ventilated.

The most commonly used insulation for wooden walls is basalt slabs with a thermal conductivity of 0.032–0.048 W / (m • K). Basalt wool is obtained by blowing up igneous basalt rock.

For exterior decoration of the facade, the undoubted advantages are the following properties of this material:

- high rates of sound and heat insulation;

- fire safety;

- resistance to biocorrosion;

- environmental Safety;

- frost and heat resistance;

- breathability;

- optimal ratio of material costs and high thermal insulation performance.

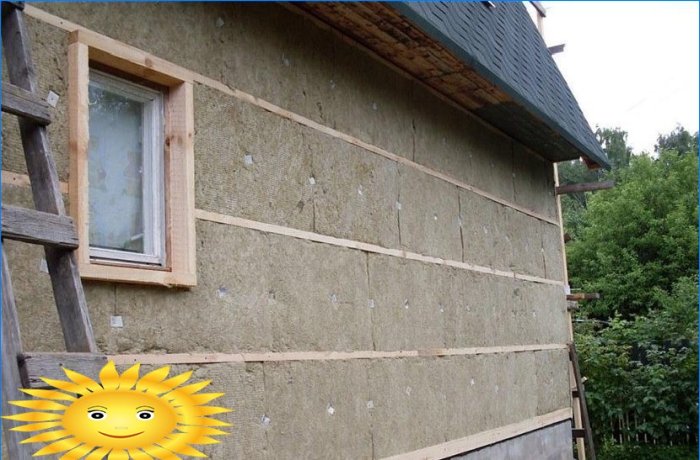

Installation of lathing

Before installing the frame for finishing with siding or clapboard, it is necessary to prepare the wall surface. If an operating house is sheathed, you need to remove all protruding elements of the facade (platbands, decor details, etc.).

It is better to replace or repair damaged parts of the wall. The slots in the joints of the timber are sealed with natural materials (jute, linen tow, felt) or with a synthetic wood sealant. The walls of a house made of timber must be antiseptic before starting work.

Wooden elements of the lathing are made of softwood, which also need to be treated with an antiseptic. The moisture content of the wood should not exceed 15%. To save material and ease of installation, it is advisable to make a drawing of the layout of the bars, according to which to prepare all the elements of the frame. The thickness of the bars is taken from 30 mm, the height depends on the thickness of the insulation.

Installation of the frame begins with framing the facade and openings. The distance between the lathing bars is determined from the conditions for the installation of the cladding (the size of the siding panel, the length of the lining board and the width of the insulation) from 400 to 1000 mm.

It is important to check the verticality and horizontalness of the surface for finishing with the help of a building level. The direction of the battens should be perpendicular to the direction of the cladding panels or boards.

For the convenience of installing intermediate elements of the battens, ropes are pulled from the corner bars from the bottom and top of the facade. You can mark all the elements on the wall with chalk.

Fasteners for installation of the battens are selected with an anti-corrosion coating or made of corrosion-resistant steel. Its amount is taken at the rate of 1 screw (nail) per 40 cm of the bar length. Depth of nail pinching when connecting elements is allowed at least 25 mm.

Thermal and vapor barrier device

The external enclosing structures of the walls in terms of thermal insulation must have the following properties:

- It is good enough to resist the passage of heat through them. The thermal conductivity coefficient is taken in the range of 0.04-0.06 W / (m • K).

- The inner surface should have a temperature that slightly differs from the temperature regime of the room.

- Resistant to unexpected fluctuations in ambient temperature.

- The structure of the wall should not be saturated with moisture, as this significantly reduces its thermal properties and reduces durability.

- Have a density of not more than 250 kg / m3, so as not to significantly load the supporting structures of the walls.

- Compressive strength for heat insulator should be above 20 kPa at 10% deformation.

External insulation of wooden walls with an air gap and external decoration with siding or clapboard can be done both during the construction of a new building and during its reconstruction. The cladding screen protects the insulation from mechanical damage, wind loads, exposure to precipitation and sunlight.

The creation of a ventilated gap prevents the accumulation of moisture in the wall structure, reduces its heat conduction, and prolongs the service life of the entire building. For a permeable finishing layer of the wall, according to the results of calculations of the humidity regime by specialists, in structures with an air gap, additional vapor barrier between the wall and the heat insulator is not required.

Insulation rolls or slabs are placed between the frame bars. The width of the heat insulator is taken 2 cm wider to create a small spacer without increasing the density of the material. It can be fastened to the wall using facade anchors, dowels, even nails, using an insulation holder or simple washers.

On the outside of the heat-insulating layer, a wind-vapor barrier device is required. To ensure a wooden structure of normal operating conditions, air access to its surface is required. That is why the use of dense airtight films as vapor barrier is undesirable..

The most effective moisture insulating material with the ability to “breathe” is diffuse membranes. They are produced with one-, two-sided and three-layer (they accumulate moisture in the inner layer, then evaporate it). For the option of wall insulation with an air gap, the use of a one-sided membrane is sufficient. Its vapor-retaining surface is located outside.

Docking of the insulating material is carried out with a minimum overlap of the sheets by 15 cm. It is better to fix the membrane with adhesive tape. On top of the vapor barrier layer, slats with a thickness of 20 to 50 mm are mounted on the lathing bars for the device of a ventilated gap. All wooden structures must be protected with an antiseptic coating.

Next, you can start the device of a protective and decorative screen from siding or lining.

Can you please provide guidance on the insulation process of a house when preparing it for clapboard or siding? I’m curious about the best practices and materials involved in ensuring proper insulation and energy efficiency. Any advice would be greatly appreciated!

When preparing a house for clapboard or siding, insulation plays a crucial role in enhancing energy efficiency. The first step is to ensure that the walls are properly insulated. This can be done by adding insulation materials, such as fiberglass or cellulose, between the studs. Another important aspect is the use of a weather-resistant barrier, like a house wrap, to prevent moisture intrusion and increase insulation effectiveness. Paying attention to any gaps around windows, doors, and electrical outlets is essential, as they can be prime spots for air leakage. Sealing these gaps with caulking or weather stripping will further enhance insulation. It’s also recommended to insulate the attic and basement areas, as they are potential sources of heat loss. Using energy-efficient insulation materials and hiring a professional to install insulation can ensure proper insulation and energy efficiency in your house.

Insulation is a vital component in improving energy efficiency when preparing a house for clapboard or siding. To properly insulate the walls, one should add materials like fiberglass or cellulose between the studs. Additionally, it is crucial to use a weather-resistant barrier, such as a house wrap, to prevent moisture and enhance insulation effectiveness. Attention should be given to sealing any gaps around windows, doors, and electrical outlets, as they can lead to air leakage. This can be achieved by using caulking or weather stripping. Insulating the attic and basement is also recommended to prevent heat loss. Opting for energy-efficient insulation materials and professional installation can help ensure proper insulation and energy efficiency in your home.

Can you please provide some guidance on how to insulate a house from a bar when preparing it for clapboard or siding?