Recommendation points

- Types of plastic pipes for internal wiring

- What time has shown – a few words about the problems during operation

- How to choose PPR pipes

- Equipment required for working with PPR pipes

- Basic methods and techniques for working with PPR pipes

- Where is the “staff” type pipe used, how to work with it

- Is it possible to use PPR pipes for distributing heating systems

- Useful Tips

Water is the most powerful solvent known to mankind. It dissolves everything. There is no chemical compound or element that can resist it. Water dissolves even the glass of the glass in which it is poured. Water determines everything on our planet – the climate, complex processes in the bowels of the Earth and in its atmosphere, it has power over life and death.

A person has been striving to conquer it from the very moment he had the first rudiments of reason, however, it took millennia for people to learn to direct water where they need to and in the required quantities. The invention of the pipe is tantamount to the invention of the wheel, and the history of the development of water supply systems is inextricably linked with the history of humanity as a whole. This is the story of some of the best pipes ever to appear on this planet..

Types of plastic pipes for internal wiring

With the advent of plastics, scientists began to actively search for materials that could solve a complex technical problem – to replace metal pipes for water supply. Steel and copper pipes have ceased to meet the needs of mankind. They are susceptible to corrosion, fail quickly, and require sophisticated equipment for production and work with them. Labor productivity when working with metal pipes is extremely limited. The new pace of development of civilization demanded new materials for pipes – cheap, reliable, easy to install.

The first attempts to realize the ambitious goals were made in the USA in the early sixties of the last century, when the first PVC and CPVC pipes were produced. The former are designed for cold water, and the latter for hot and heating systems. These pipes immediately became very popular in America. Indeed, to work with them, no tools are required, except for special scissors, and the pipes are connected to each other and the bends are made with ready-made factory glue fittings. These pipes appeared in Russia in 1993 and were supplied from the USA. Now they are produced in our country under the license of the well-known American company FlowGuard Gold ™ on its equipment.

Another plastic that was used as the basis for multilayer pipe systems – polyethylene due to the difficulties with interconnection and the complexity of the production technology of multilayer pipes, which are needed to simplify the work with fittings and reduce the coefficient of linear expansion, was mastered much later. Full-fledged cross-linked polyethylene pipes appeared in England in 1979. They have appeared in Russia since 1998. These pipes, with all their shortcomings, have great prospects and are currently being developed more and more new modifications..

Polypropylene has a high melting point and is perfectly suited as a material for water pipes. If the resistance of the best samples of CPVC pipes hardly reaches 100 degrees, metal-plastic pipes up to 120 degrees, then polypropylene, due to its chemical properties, has a melting point of 162 degrees and tolerates temperature and pressure changes well. PPR pipes began to be produced in 1958-1959 in Italy and the USA. To work with them, simple equipment is required, and the constant improvement of technology has significantly improved their performance. PPR pipes remain the most commonly used in heating and water supply systems of particularly critical places.

What time has shown – a few words about the problems during operation

The most reliable checker is time. Plastic pipes have not been present on the Russian market for long, but certain conclusions can already be drawn. A common drawback of all plastic pipes, regardless of their type and place of production, is low strength. Steel pipes give one hundred points ahead of this indicator. If it is almost impossible to pierce a steel pipe with a drill, then all types of plastic are easily damaged. The following problems were noticed for the types of pipes:

PVC pipes, designed for an operating temperature of no more than 40 degrees, are indeed very dangerous to expose to heating. At a water temperature of 60 degrees, they turn into a soft mass that breaks and spreads literally before our eyes. They pose a great risk of flooding if a boiler with an old check valve is installed in the system, and the water is often turned off or pressure drops occur. One has only to go hot water to the cold water main from PVC pipes – trouble cannot be avoided. CPVC pipes are more resistant, but the manufacturer has given them a maximum operating temperature of 87 degrees. Boiling water is kept for a short time. With constant heating, they become tough, but brittle. Can be easily broken by accident. There are lots of CPVC pipes in which there is an excess of chlorine. After five to seven years they begin to sweat and become covered with a fine mesh of cracks, and after 12 years they crumble. If the batch is normal, then the pipes hold up well. Conclusion: it is better not to use a PVC pipe at all, and to distribute all lines only with a CPVC pipe.

Reinforced-plastic pipes differ greatly in quality. There is no guarantee that a pipe from a well-known manufacturer will hold up better than its Chinese counterpart. They are very critical to water quality. It is better not to use it to connect central heating radiators and hot water distribution in the city. The water in Russian water pipelines does not meet the standards for drinking water, and its chemical composition is impressive with the abundance of various salts, which behave uneasily when heated. There have been cases when a metal-plastic pipe fell into disrepair in just five years. There is only one defect – loss of elasticity, cracking and destruction. Conclusion: a metal-plastic pipe can be used in urban environments for distributing cold water in an apartment. In the individual construction of a country house, if you have your own autonomous well and a water treatment system, it can be used for any purpose.

At first, the PPR pipes did not like the Russian consumer very much, since work with them was paid more because of the need for skilled labor of a foreman with a soldering iron. In addition, to repair such pipes, you need to call a specialist with a soldering iron again. The mentality of Russians is as follows – let it be done by a professional, but then we will repair it ourselves. It will take a long time to finally defeat this trait, but there is already progress towards improvement. Over the years, the consumer realized that these pipes are the most reliable. This is evidenced by a dumb fact. In the 90s, all the wiring in houses was done with metal-plastic, and today no construction company for some reason uses it for the installation of risers and internal wiring of the water supply network. Today, metal-plastic can be found only in autonomous heating systems. Conclusion: the PPR pipe can be used without fear that it will burst under pressure, the fitting will disperse or microcracks will appear in any home systems.

How to choose PPR pipes

The most problematic place of all plastic pipes is still a large coefficient of linear expansion. That is, when heated, they lengthen, and when cooled, they contract. The fight against this property of pipes has led to the emergence of multilayer pipes. Including PPR. In view of the fact that the cost of reinforced pipes is higher than single-layer pipes, when drawing up a wiring diagram for large objects, the economy factor plays an important role. With internal wiring around the apartment, you can also save a certain amount, knowing the properties of the pipes.

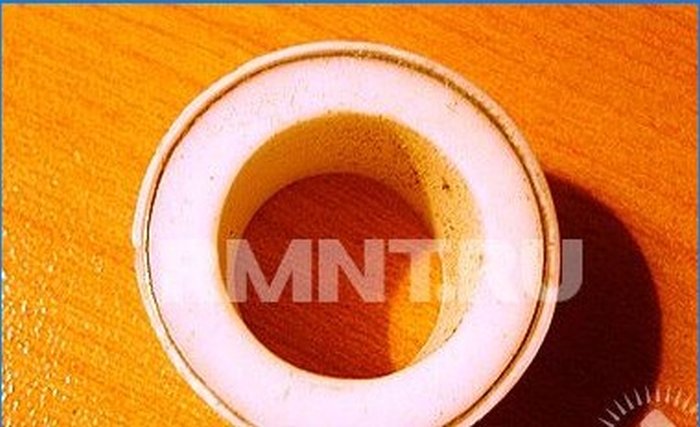

Photo 1 shows a sample of a single-layer classical PPR pipe. It comes in two types – for cold and hot water. Pipes intended for hot water supply are marked with a red stripe along their entire length. They contain additives to stabilize polypropylene when heated. But it will not be a big mistake if pipes without marking are used for distributing hot water in a small apartment. Serious changes in dimensions during heating of such pipes begin in straight sections from three meters. Single-layer pipes can be safely used for distributing cold water and hot water supply with small lengths of straight pipe sections.

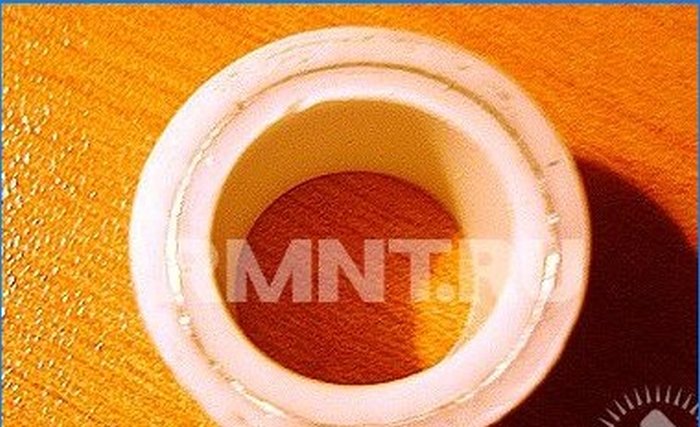

Photo 2 shows the so-called “staff” type pipe. It was developed by German designers in 1997. This is a successful design that combines the positive qualities of plastic pipes with metal ones. As you can see in the photo, the outer shell of such a pipe is made of aluminum, covered on top with a thin layer of polypropylene. These pipes are versatile. They can be used in any systems – from cold water supply to heating. Their cost is 50-70% higher in comparison with single-layer PPR pipes. Most often they are used for the installation of heating systems. They have a low coefficient of expansion and are more bending stability. They have one drawback – to work with them, a special stripping is required, with the help of which the top layer of metallization is removed before soldering..

Photo 3 shows a sample of a modern PPR pipe. It is a multilayer pipe with a reinforcing layer sandwiched between two plastic layers. It is applicable in all cases, as the “headquarters”, but to work with it you do not need to clean up. In addition, this type of pipe has higher temperature and pressure ratings. It can operate at a pressure of 6 bar and a temperature of 95 degrees. At a liquid temperature of 70 degrees, a working pressure of 10 bar.

Photo 4 shows the latest type of PPR pipe with internal fiberglass reinforcement. The color of the fiber on the cut can be red or blue. Accordingly, pipes must be used to transport hot or cold water. This pipe is somewhat cheaper than a pipe with internal aluminum reinforcement and has a high coefficient of expansion. Its plus is that it is the lightest of all PPR pipes and is not inferior in strength to its metallized relatives. Can be applied anywhere.

The main share of PPR pipes in Russia is made in Turkey. Its market share has grown significantly over the past three years. Before that, Poland and Germany were in the lead. The quality of Turkish pipes is high, and the price is significantly lower compared to German counterparts. So, on average, a running meter of a pipe with an inner fiberglass reinforcement of Turkish production with a diameter of 20 mm costs 60 rubles, and a German pipe will cost 80 rubles.

Equipment required for working with PPR pipes

PPR pipes are connected to each other by means of factory-made fittings. The method of connecting all types of PPR pipes is brazing. For this, a special soldering iron is used. There are many models of these devices, but they all have the same device. Photo 5 shows one of these soldering irons..

It consists of a handle, a heating element in the form of a thick copper plate of a specific shape with two holes for simultaneous installation of two nozzles and a thermoelement body with holes for cooling and a power regulator with two LEDs indicating the state of the soldering iron. Power is regulated by potentiometer from 1 to 6.

The soldering iron comes with the accessories shown in photo 6.

These are four paired nozzles for soldering pipes with a diameter of 16, 20, 24 and 32 mm with a Teflon coating, a clamp for fixing the soldering iron on a table or other surface, which is convenient for working with a large number of small parts. Allen key for changing nozzles and soldering iron stand.

Pipes of the required length are cut with special scissors, the designs of which have been invented a lot. In general terms, they look the same and consist of two handles, one of which is fixed and rigidly connected to the semicircular bed. It has a slot for the blade, and the second handle activates the ratchet mechanism, which transfers the force from pressing the blade, which cuts the pipe. A general view of such Czech-made scissors made of heavy-duty plastic with a convenient blade return mechanism is shown in photo 7-8.

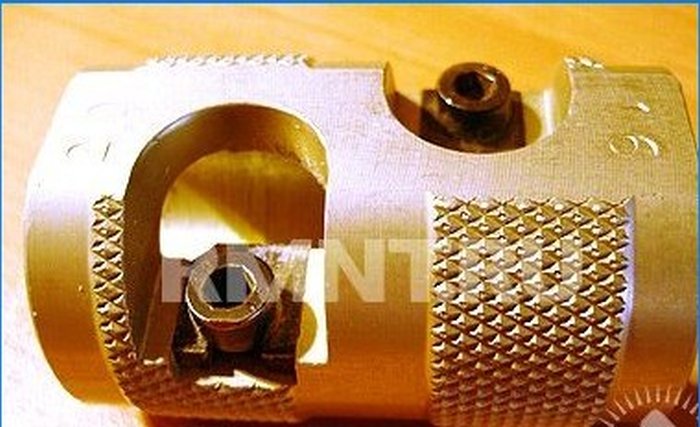

To work with a pipe “staff”, having external metallization, a stripping is used, shown in photo 9. One such device has calibrated holes for pipes of two adjacent diameters, which are indicated on the body by the corresponding numbers. This device works on the principle of a pencil sharpener, removing the top layer of aluminum at a fixed length and depth.

In addition to the devices and accessories shown for the installation of water supply and heating systems from the PPR pipe, you will need a screwdriver, a perforator, a jackhammer, a tape measure, a pencil or marker, a water or laser level.

Basic methods and techniques for working with PPR pipes

The sequence of work with a PPR pipe is as follows:

- Markup

- Mounting mounts

- Main line soldering, bend soldering

- Removing bends

- Tie in the riser

- Water start-up and leak test

The marking starts from the place where the plumbing fixture will be installed. As an example, the sequence of work on the supply of cold and hot water lines with external wiring to the kitchen sink will be shown. In this example, it is necessary to calculate the installation locations of the wall elbows for the transition to metal from plastic, to carry out the wiring of the PPR pipe from the sink to the basement room through the interfloor ceiling. The hole in the overlap was prepared in advance, the installation locations of the wall elbows are indicated in photo 10 with a marker (circles of a smaller diameter to the left and right of a circle of a larger diameter, indicating the location of the sewer outlet).

From the places where the wall mounts are installed, using the horizontal and vertical level, lay lines on which the locations of the pipe mounts are marked. The fittings must match the pipe diameter. The fasteners are installed depending on the wall material on dowel-nails or self-tapping screws, as in this case (here the walls are sheathed with OSB).

Pipes are most often sold in whips of a certain length. As a rule – 4 m. Such a pipe is usually cut in half in a store, as it is inconvenient to transport. First, the elbow is soldered and a two-meter pipe cut and a standard fitting are taken for this. In this case, pipes with a diameter of 20 mm with internal aluminum reinforcement and fittings of the same diameter were used. All fittings for PPR pipes are universal – that is, they are suitable for any of its types, both with and without reinforcement.

The soldering process is shown in photo 11. A nozzle of the corresponding diameter is installed on the soldering iron. The convex part is for the fitting, and the opposite part is for the pipe. After the soldering iron is plugged into the outlet, you need to wait until it heats up. The heating to the desired temperature is indicated by the indication of the soldering iron, which each type of this tool has its own. Then they take the fitting in one hand, the pipe in the other and simultaneously insert it into their half of the nozzle. As it heats up, you need to press on the parts from both sides until they reach the stop, after waiting 10-15 seconds, quickly remove the parts from the nozzle and insert one into the other, pressing tightly, hold them in this position for about half a minute and release. After a few more minutes, the parts will grab and it is no longer possible to separate them. You can proceed to the next node.

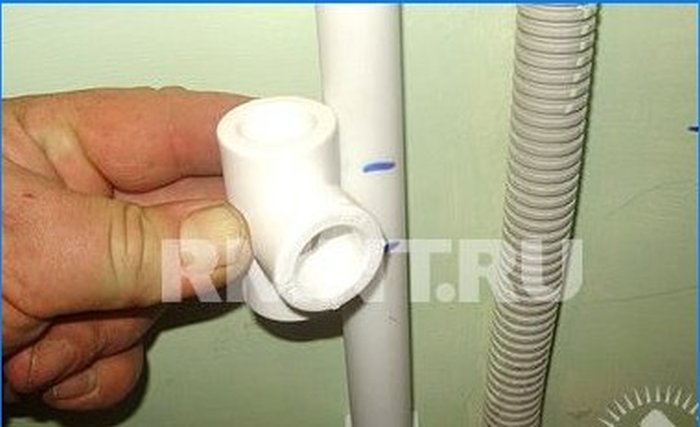

This is the simplest soldering technique. A more difficult technique is soldering in place. So you have to solder parts that don’t make sense to measure out separately. The soldering iron has such a shape that you can get with it almost everywhere, you just need to remember that the nozzle with which you have to work should be in the first place, and the additional one can be installed in the second position. In this example, you need to cut a tee into the cold water pipe to drain the water. This is done as follows. First, mark the place for the tee, as shown in photo 12. It is not necessary to use a measuring tool in such cases. It is necessary to attach the tee in place and set aside two centimeters from its ends to the center. Mark these places with a marker or pencil after a short workout, such marking is done quickly and accurately, which significantly saves time.

Then the pipe is cut along the marks using scissors (photo 13) and soldered in the same way as described above, only not the pipe is carried to the soldering iron, but the soldering iron to the pipe. The process is clearly shown in photo 14. After heating the pipe and the tee, they must be removed from the soldering iron and quickly connected, having stood for about 30 seconds (photo 15)

And the last trick to master is soldering with two nozzles. This is sometimes necessary when you need to make a transition from one pipe diameter to another. For this, a special fitting is used – a reduction. It has on one side a hole for one diameter, and on the other – for the second. Soldering is carried out in two stages. The larger diameter on the reduction goes to the smaller pipe – this is like the side of the fitting. Do not confuse places! First, a reduction and a smaller pipe are soldered on a nozzle of a smaller diameter, and then a reduction and a large pipe (or a fitting of a larger diameter, as in photo 16-17).

By combining these three techniques, you can quickly master the soldering of polypropylene pipes. The main thing is that the tool is always ready!

Where is the “staff” type pipe used, how to work with it

As it was already mentioned, the “staff” pipe has external metallization and was designed to reduce the linear expansion of polypropylene when it is heated. In order to solder it, you must first remove the aluminum layer from it by stripping the pipe diameter that is supposed to be soldered. To do this, the pipe is inserted into the stripping hole and the device begins to rotate around the axis clockwise, pressing on it. The cutter, which is inside, is set to a certain thickness of the removed layer, will begin to work, and the chips will go. You need to rotate the stripper until the pipe rests against the limiter and the chips break. The process is shown in photo 18. The result should be a clean, neat tail that can be soldered like a regular pipe (photo 19). Considering that the stripping takes place two centimeters deep into the pipe and about that the pipe passes inside it empty, you need to be careful when marking short pipe sections and avoid their length less than 4-5 cm.In an extreme case, you can remove the metallization with a sharp knife.

Is it possible to use PPR pipes for distributing heating systems

If fifteen years ago it was impossible to give an affirmative answer to this question with absolute certainty, today it is possible to do the wiring of heating systems with a PPR pipe without a doubt. Moreover, this is true both for heating systems with natural circulation, and with forced (open and closed heating systems). PPR pipes have made a big leap forward during this time. But for heating systems, only a pipe with reinforcement should be used. Moreover, for pipes with fiberglass reinforcement, it is necessary to solder expansion joints (fitting in the form of a loop) every four meters of the line running in a straight line. Installation of expansion joints is not required for pipes of the “staff” type and pipes with internal metal reinforcement. For uniform circulation of the coolant in the heating system, it is advisable to use collectors that distribute the fluid flows equally across different branches of the heating system. In addition, it is possible to reserve a place on it for connecting an additional heating circuit in case it is necessary to increase the heat output (photo 20). And for the convenience of servicing the radiator, you need to install battery valves with detachable connections (photo 21). As a valve, you can use a special valve – a thermostat, which maintains the set temperature of the battery depending on the set temperature. This is a very efficient way to maintain the desired room temperature and provides good fuel economy..

Further prospects for the development of plastic pipes, regardless of their type, are very bright. Already today, all new buildings are equipped exclusively with plastic pipes. It is fast, clean and environmentally friendly in installation, maintenance and disposal, and most likely there will be no winners in the competition – all plastic pipes will find their own niche in the market.

Useful Tips

In hard-to-reach places, you don’t need to solder the pipe. To avoid this, it is better to solder such segments in advance, and connect them outside such a place through PPR couplings.

Some connections will need to be disassembled during operation. The easiest way is to cut the pipe in this place and solder the collapsible joint, so that later it will be easier to service it.

If some connection did not work out, then it can be redone using a coupling

It is desirable to make the outlets to the batteries smoother. To do this, instead of each one knee at 90 degrees, you need to use two of 45.

To bypass another pipe, you need to use a special ready-made bypass (see photo 21)

If it is not possible to warm up both the pipe and the fitting in place at once, then this can be done one by one, but the time for warming up one of the parts is doubled.

Can anyone provide guidance on the step-by-step process and considerations for installing a water supply system using polypropylene pipes inside a house? Which fittings and tools are necessary, and are there any specific precautions to take during the installation? Any recommendations or personal experiences would be greatly appreciated!