Recommendation points

- How an indirect heating boiler works

- Varieties and selection of devices

- What heating systems are boilers used in?

- Installation and piping diagram of an indirect heating boiler

- Operation and maintenance

Indirect heating boilers are considered to be one of the most rational and versatile devices that can provide a private house with hot water. In this article we will talk about the economic justification, the principle of operation, the installation scheme and the features of the operation of these devices..

How an indirect heating boiler works

The flask design of indirect heating boilers is the same as that of electric or gas boilers: a stainless steel tank with an inner coating and thermal insulation. Instead of heating elements, a coil-heat exchanger is installed in them, through which hot water of the heating system flows.

It may seem that the temperature of 50–70 ° С will not be enough to heat water, because much higher rates take place in gas and electric water heaters. But due to the large area of contact, the heating rate is not inferior to other devices, and sometimes it is even higher.

The device of an indirect heating boiler with a coil: 1 – cold water inlet; 2 – hot water outlet; 3 – protective anode; 4 – central heating entrance; 5 – thermal insulation; 6 – heat exchanger; 7 – central heating outlet

Indirect heating boilers also have a sacrificial anode, but the safety group, as a rule, is not included in the design. Such simplicity of the device, on the one hand, is characterized by a long service life, on the other, it requires a thorough approach to drawing up a communication diagram and strapping.

Indirectly heated boilers require a large enough room for installation. They are mainly equipped with objects without an additional chimney or the presence of a water heater in a gas supply project. In such cases, the only alternative is a double-circuit boiler, but in summer it is inconvenient to use it, and the re-equipment of heating and hot water supply systems can cost a pretty penny.

Varieties and selection of devices

In addition to tanks of elementary design, there are also boilers of a more complex device that allow you to implement some wonderful functions when integrated into a heating system.

One of the most demanded functions is the use of a boiler as a heat accumulator. This is especially important when electric heating with an unstable power supply or when operating at daily rates. Devices with heat storage mode have a significant capacity (more than 300 liters) and reliable thermal insulation.

Boilers with a recirculation system that provide instant hot water to the mixer are considered more expensive. They have three branch pipes for connecting to the DHW system: one for cold water supply and two for hot water flow. The circulation is carried out by a small built-in pump. Boilers of this type are less economical, but they can be used to organize a small heating circuit, for example, to install a heated towel rail.

Some boilers have a tank-in-tank design, the name speaks for itself. The external tank contains the heating medium of the heating system, the internal tank contains heated tap water. The advantage of this design is that water is heated very quickly, but due to the complexity of the device, such boilers are much more expensive than conventional ones..

Boiler of indirect heating “tank in tank”: 1 – cold water inlet; 2 – hot water outlet; 3 – central heating entrance; 4 – inner tank made of stainless steel; 5 – central heating outlet

What heating systems are boilers used in?

Almost any heating unit can work in conjunction with indirect heating boilers, but the use of devices of different classes has its own characteristics. In general, the simpler the boiler design, the clearer the scheme of work, but the higher the complexity of the piping. For example, for a standard flue gas boiler with a thermostat, you can independently select the connection point depending on the configuration of the heating circuit. This is not so easy to do with an integrated heat pump, and electronically controlled boilers can malfunction during the summer..

Solid fuel and liquid fuel boilers cannot be used in summer, but in winter this is one of the most acceptable options. Electric heating boilers also work productively; for greater convenience, they can be equipped with an additional thermocouple or automation with remote sensors to regulate the work according to the temperature of the water in the tank.

It is most difficult to connect an indirect heating boiler to gravity systems. With a slow circulation, the water is not heated so efficiently, and to use the pump, you must choose the right connection points to the heating system so as not to disrupt the heating operation. The correct solution would be a sequential tie-in into the return line with the organization of a long bypass, in which the pump and the boiler are connected in series, and a check valve is installed on the flow line.

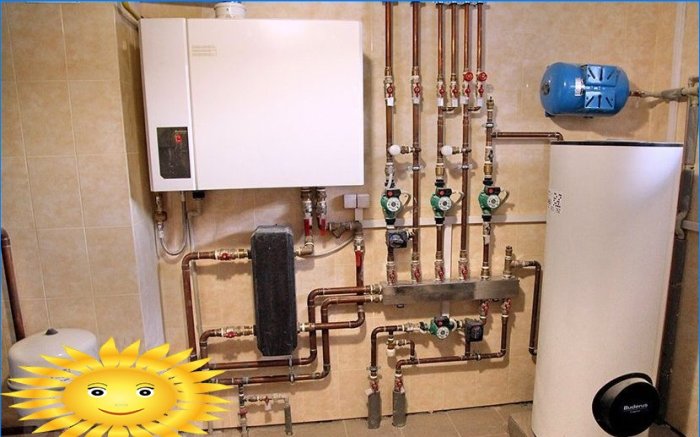

Installation and piping diagram of an indirect heating boiler

There are three options for connecting to the heating system, and they all imply the installation of a boiler at a minimum distance from the boiler. The boiler should be placed on a sufficiently solid foundation and strictly level. The heating medium must be injected from the top, the outlet must be from the bottom. On the other hand, hot water is drawn from the top and make-up from below..

Option 1.The heating supply pipe is divided into two branches, each of which has shut-off valves or a three-way valve. One branch passes through the boiler, the other shorts the line if water heating is not needed. This method is optimal for constant use of the boiler or seasonal operation. In this case, the temperature can be controlled by two self-resetting solenoid valves connected through a three-contact thermostat relay.

1 – cold water supply; 2 – shut-off valves; 3 – mesh filter; 4 – check valve; 5 – security group; 6 – heating radiator; 7 – heating boiler; 8 – boiler safety group; 9 – circulation pump; 10 – three-way valve; 11 – electromagnetic valve; 12 – expansion tank of the DHW system; 13 – hot water to consumers

Option 2.The supply pipe has a branch to which a circulation pump and a boiler are connected in series; on the other hand, the connection is made to the return flow pipe. The pump is switched on through the thermostat relay circuit, thus, when the temperature of the water inside the boiler drops, it activates forced circulation and accelerates heating. The heating circuit has its own pump installed on the supply pipe after the boiler connection. This option is optimal if the boiler is used infrequently or if the water temperature is lower than in the heating system..

1 – cold water supply; 2 – shut-off valves; 3 – mesh filter; 4 – check valve; 5 – security group; 6 – DHW circulation pump; 7 – boiler thermostat; 8 – radiator; 9 – heating boiler; 10 – boiler safety group; 11 – heating system circulation pump; 12 – expansion tank of the DHW system; 13 – hot water to consumers

Option 3.The boiler is connected in series with the boiler feed pipe through a circulation pump. With this connection, the boiler always operates in the heat storage mode, the option is optimal for devices with recirculation. The presence of a bypass connecting the coolant outlet from the boiler with the boiler return makes it possible to use the DHW system in summer.

1 – cold water supply; 2 – shut-off valves; 3 – mesh filter; 4 – check valve; 5 – security group; 6 – bypass; 7 – heating radiator; 8 – heating boiler; 9 – boiler safety group; 10 – circulation pump; 11 – expansion tank of the DHW system; 12 – hot water to consumers

With any connection scheme, it is necessary to install shut-off valves on all pipes of the boiler and the circulation pump. Connecting the boiler to the DHW system necessarily requires the installation of an expansion tank with a membrane on the water supply side to compensate for the pressure of the heated liquid. A strainer and a check valve must be installed on the cold water supply pipe to the safety group..

Operation and maintenance

Every 2–3 years, the boiler needs a complex of maintenance, similar to electric water heaters: flushing the tank, removing scale, replacing the sacrificial anode when it is thinned by more than 50%, replacing the gaskets. It is reasonable to carry out the inspection with the removal of the technical flange of the tank in the summer, in conjunction with the maintenance of the heating system. The chemical flushing of the heating circuit and the boiler coil must be carried out separately using appropriate cleaning agents. Otherwise, these devices are very unpretentious..

What are the different types of devices used for indirect heating boilers? Can you provide examples of connection diagrams and explain the piping system for these boilers?

Can someone provide more information on the different types of devices used in indirect heating boilers, as well as any available connection diagrams and piping configurations?