If the gas will not reach you soon, and among other things, electricity is supplied intermittently in winter, then in order not to while away days and nights in a cold house, a solid fuel boiler will help solve the heating problem.

As strange as it sounds today, but if you choose heating equipment, then you need to pay attention not only to the technical parameters, but also to the fact that no one has yet canceled such natural phenomena as snow, rain, wind.

All builders are well aware that a house starts with a stove – with the simplest and most reliable solution, when there is no gas in the house and frequent power outages occur. The stove is located in the middle of the house and can give off heat after warming up to all the rooms around it. However, those who used the stove know that it can smoke, smoke, and you can’t get enough firewood for it, and if you miss the moment of throwing them up, you risk being left without heat on a frosty night, and the stove will have to be re-heated. And finally, do not forget that it is a likely source of fire, and therefore, when building a house, today, instead of a conventional stove, a solid fuel boiler is installed.

Solid fuel boiler is a modern heating device that runs on traditional fuel, it does not need gas, electricity or liquid fuel.

By design, it resembles an ordinary stove – it has a window for supplying firewood, a firebox, an ash pan, a chimney. However, thanks to modern technologies, a boiler is made from completely different materials than a stove, namely from cast iron or sheet steel.

Cast iron boilers are the most durable and capable of accumulating more heat, but they need to be operated extremely carefully, because cast iron is a rather fragile material and is capable of cracking from a sharp temperature drop or from a sharp jump.

Boilers made of sheet steel are less susceptible to destruction from sudden changes in temperature, since steel is a ductile material. The walls of such a boiler are thinner than the walls of a cast iron one, and in order not to get burned, the outer part of the body is isolated from the inner one by modern non-combustible materials. So if you live in a country house permanently, then it is best to purchase a solid fuel boiler made of cast iron. And if you live in a city, and you visit the house and only heat it during your presence, then it makes sense to install a steel boiler.

A steel solid fuel boiler can also be used as an auxiliary boiler if gas or electricity interruptions frequently occur in your area. If desired, some elements of the boiler can be replaced or new ones added in order to switch to a new type of fuel (gas or liquid fuel). This procedure is simple and the home craftsman will be able to install an inflatable burner for a certain type of fuel on his own, so a multi-fuel boiler will be useful even where there is today the possibility of using conventional furnace fuel, and in the future it will be possible to conduct gas. True, here you need to take into account one nuance – the efficiency of such a converted boiler will be slightly lower than that of a boiler specially designed to work with gas.

If a classic stove is a self-sufficient system, then a solid fuel heating boiler is just a source of heat – the heart of the heating system. A heating system is a set of interconnected elements that are responsible for heating a building. In addition to the boiler, heating system elements are pipes and radiators. The role of the coolant in the system is played by ordinary water. Being heated in the heat exchanger of the boiler, it moves through the pipes to the radiators, transfers heat through them to the room, returns to the boiler for new heating and the process is repeated again.

Heating radiators are mounted in rooms in such a way as to evenly warm the air in them, creating a stable microclimate. Thanks to this, the heating system completely warms up the house, unlike a conventional stove, from which the farther you are, the less comfortable you feel..

The heating radiator, which has a power regulator, allows you to change the heating temperature in the room, if some of them are empty. There is no need to keep them at room temperature – 15-18 degrees will be enough to maintain normal humidity. Due to the fact that the solid fuel boiler is compact enough, it can be installed in any separate room and even in the kitchen.

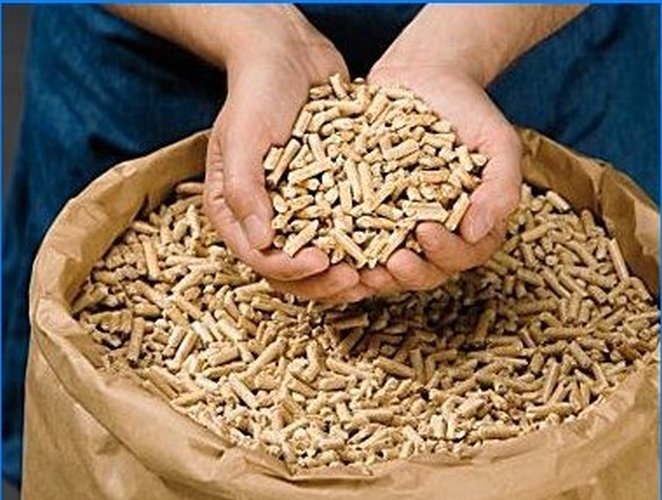

Anything that is burned in a conventional stove can be used as solid fuel for the boiler: firewood, wood chips, woodworking waste, coal, peat and special pressed fuel briquettes – pellets.

Pellets are made from wood waste, which are crushed and pressed into small pellets in the shape of a cylinder. Their size ranges from 6 to 14 mm in diameter and no more than 70 mm in length. For the production of this type of fuel, no chemical components are used, and therefore pellets are environmentally friendly material and at the same time have a high combustion heat. The use of pellets makes it possible to reduce the presence of a person in the operation of the boiler by automating the process of feeding pellets into the boiler. When transported in a car and stored in a private house, they take up little space.

Despite the fact that a solid fuel boiler generates heat due to the combustion of solid combustible materials in it, this does not mean at all that everything that burns can be thoughtlessly thrown into it. In order to obtain the highest possible efficiency and at the same time maintain the service life of the boiler, it is recommended to use the driest wood as fuel..

Here is a specific example: when burning firewood containing 20% moisture, the heat of combustion of one kilogram will be from 4 to 4.5 kW / h, and if the firewood is 50% wet, then you will get a heat of combustion of no more than 2 kW / h per 1 kg of wood. It turns out that in order to heat a house, you will need twice as much dry firewood. Raw fuel burns poorly and unstably, it produces little heat, but a lot of smoke and as a result, the life of the boiler and chimney is significantly reduced.

But not everything is so simple with dry wood, since its combustion process is uneven. As soon as you put the firewood on, at first they burn weakly – they flare up. Then the wood begins to actively burn and generate heat in huge quantities, increasing the temperature in the boiler. As a result, a lot of energy is released in a short period of time, which a conventional heating system cannot completely consume and transfer this “extra” heat to the room.

To prevent the system from malfunctioning as a result of overheating, excess heat goes out through the pipe to the street, so the question arose to make the operation of the boiler and the system as a whole more uniform and stable, and for this, the excess heat must be somehow accumulated. This requires a heat accumulator that uses excess heat for heating and domestic hot water. If the heat accumulator is correctly selected for the boiler, then the boiler can be filled with fuel two or three times a day..

Like a stove, a solid fuel boiler requires cleaning the ash pan from ash, though not so often. If you heat a private house, then you probably have a personal plot and ash can be used as fertilizer.

There are models of boilers in which the fuel burns almost completely, leaving almost no ash, just do what you throw in the wood. These boilers are called gas generating or pyrolysis boilers. In them, the wood is first completely dried at a high temperature and a small amount of oxygen, turning into charcoal and a volatile part – a pyrolysis gas that burns with high efficiency. As it burns, the gas interacts with active carbon and, as a result, the smoke leaving the boiler contains much less harmful impurities..

A gas-fired boiler emits three times less carbon dioxide into the air than a conventional wood-fired boiler, not to mention a coal one. Very little soot and ash are released during pyrolysis combustion, and therefore the gas-generating boiler needs less cleaning than a conventional one. The operating time of such a boiler from one load of firewood is several times higher than the operation of an ordinary wood or coal stake. The only drawback of a gas-fired boiler is its high cost, which is usually 1.5-2 times higher than the cost of a conventional boiler, but economical fuel consumption and ease of maintenance make these boilers more and more popular..

Can someone provide guidance on how to select the appropriate solid fuel boiler for home heating? What factors should be considered, such as efficiency, cost-effectiveness, and environmental impact? Any specific brands or models that you recommend? Any advice or personal experiences would be greatly appreciated!