Recommendation points

- Varieties of retaining walls

- DIY concrete retaining wall

- Calculation of a massive concrete retaining wall

- Sequence of work

A retaining wall is a building structure that keeps the soil mass from collapsing when there are differences in planning marks. The high responsibility of such structures is due to the large loads of earth masses and requires knowledge of the technology of their construction. The proposed version of the concrete retaining wall will help to make it right.

Varieties of retaining walls

A retaining wall is constructed in cases where the slope of the soil or embankment exceeds the maximum value. They are classified according to height, design and material..

Height:

- low – the difference in planning marks is less than 10 m;

- medium – the drop is from 10 to 20 m;

- high – with a height difference of more than 20 m.

By design:

- massive;

- thin-walled;

- anchor.

1. Flexible support with anchorage. 2. Massive retaining walls: a – with vertical edges; b – with a vertical front and an inclined back face; c – with an inclined front and vertical back face; d – with two edges inclined towards the embankment; e – with a stepped rear edge; f – with a broken back edge. 3. Thin-walled retaining walls: a – corner console; b – corner cantilever with a tooth; c – corner buttress; d – corner with anchor rods

By material:

- reinforced concrete;

- concrete;

- brick;

- stone;

- wooden;

- gabion.

Brick retaining wall

Stone retaining wall

Wooden retaining wall

Gabion retaining wall

Massive retaining walls provide stability against shear and tipping over by their own weight. In thin-walled, in addition to its own weight, the weight of the soil is taken into account, which is included in the work in accordance with the design of the wall.

Retaining walls are monolithic, prefabricated and prefabricated monolithic. Structurally thin-walled retaining structures are subdivided into:

- corner console;

- corner anchor;

- buttress.

Anchor retaining walls are used for high level differences. Each soil has its own physical and mechanical properties. For example, if the concept of a collapse prism exists for it, then the anchor plate should be located outside of it..

Flexible retaining structures can have small deflections and displacements, which are limited by codes. If there are weak soils at the base of the retaining structure, pile foundations are used for the walls.

The dimensions of the retaining walls are taken during the calculation, which takes into account:

- wall weight;

- ground pressure;

- loads within the collapse prism;

- loads on the front of the wall and other possible forces arising in each specific case.

The retaining structure is calculated for the bearing capacity of the soil and the wall itself, shear stability. For difficult construction conditions, the calculation takes into account all additional loads.

In the case of water-saturated soils, drainage is done. This reduces the load on the wall from the soil. Sometimes the soil contains aggressive components in relation to concrete or metal. In this case, the construction of the structure is done taking into account the protection of structures from corrosion..

The height of the retaining wall directly depends on the height of the layout difference. For massive structures, the size of the sole can be taken as 0.5–0.7 wall heights. The smallest size of wall sections is allowed for:

- rubble concrete – 600 mm;

- concrete – 400 mm;

- reinforced concrete – 100 mm.

When determining the depth of the retaining walls, all requirements are taken into account as to foundations, but not less than 600 mm for non-rocky soils and 300 mm for rocky.

DIY concrete retaining wall

The choice of retaining wall material depends on:

- the purpose of the structure;

- the height of the difference between the planning marks;

- physical and mechanical properties of soil;

- the presence of groundwater;

- design solution of the structure.

For retaining walls, it is recommended to use concrete with a class of at least B15. If the operating conditions imply freezing and thawing alternately, then the brand for frost resistance and water resistance is important..

So, for example, in conditions of unstable water saturation of the soil for temperatures from -20 to -40 ° C, the frost resistance grade is allowed at least F50. Massive retaining walls are made of concrete, since thin ones are subjected to bending loads, and concrete can only work in compression.

Calculation of a massive concrete retaining wall

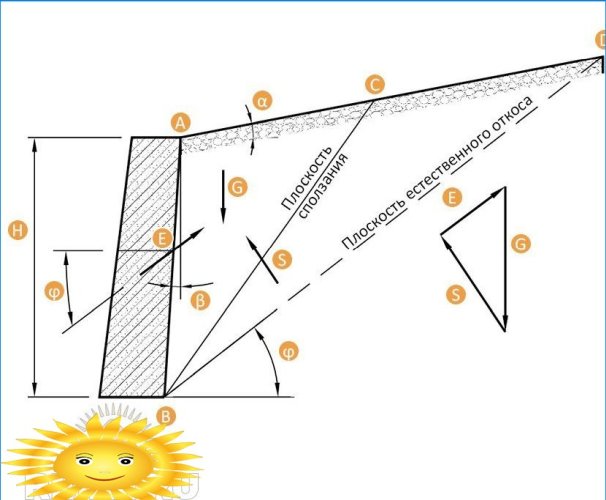

Each soil has an indicator – the plane of the natural slope. It is formed due to the frictional forces of soil particles and is characterized by the angle of internal friction -?. In nature, such planes can be found on natural slopes or embankments..

If the angle of the slope, which is required in construction for any structure, exceeds the angle of internal friction, then a retaining structure for the soil is made – a retaining wall. It must hold the soil above the plane of the natural slope.

The dimensions of the retaining wall are selected as a result of strength and stability calculations. For this, the value of the soil pressure on the structure is determined – E.

For the calculation, the theory of loose bodies is used, according to which, under its own weight (G), the soil tends down the plane of the aircraft creep and presses on the retaining wall (E). S – soil pressure on the sliding plane. In this case, the ABC prism is assumed to be a rigid body with weight G, which must balance the forces S and E.

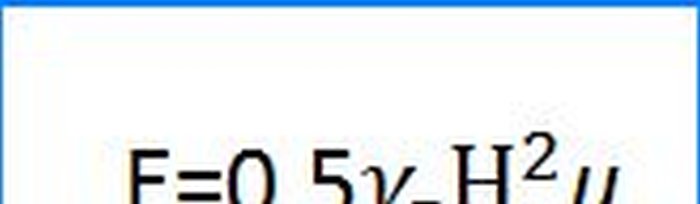

The E value is calculated by the formula:

- ?r – volumetric weight of soil (standard);

- Н – retaining wall height;

- µ is a coefficient that depends on ?, ?, ?, ?0.

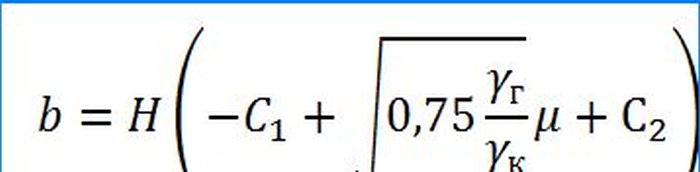

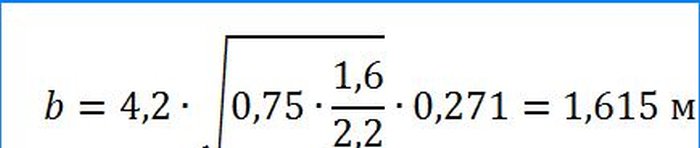

Consider a simple option – a retaining wall made of rectangular concrete. For a preliminary selection of the section of the retaining wall, you can use the formula:

- b is the width of the wall in any section;

- Н – section height from the ground surface;

- FROM1, FROM2 – coefficients that depend on the angles of inclination of the outer and inner surfaces of the retaining wall. For the case under consideration, with a rectangular section, their value is equal to zero;

- ?r and ?to – volumetric weight of soil and wall material;

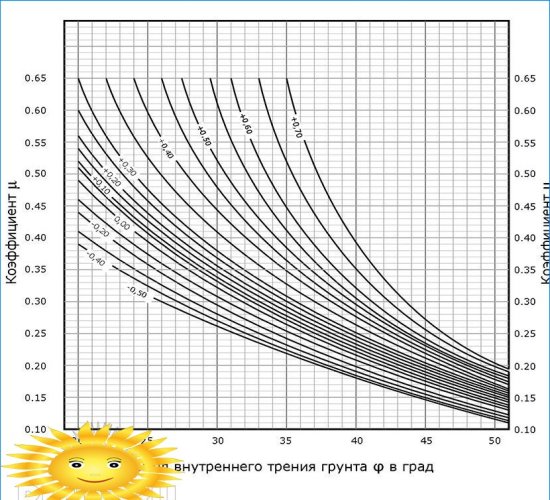

- µ – coefficient that can be taken according to the schedule.

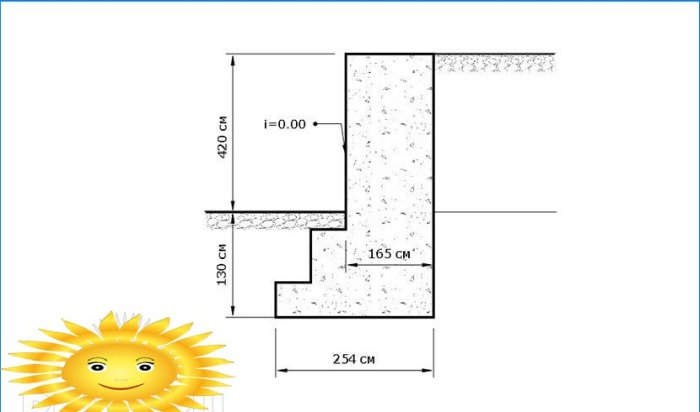

Let’s take soil as an example? = 35 ° with a bulk density of 1.6 t / m3, volumetric weight of concrete – 2.2 t / m3. The depth of the foundation will be taken as 1.3 m.In the case of a rectangular section C1 = C2 = 0.

H = 4.2 m; µ = 0.271 – according to the schedule.

Substituting all the data in the formula, we get:

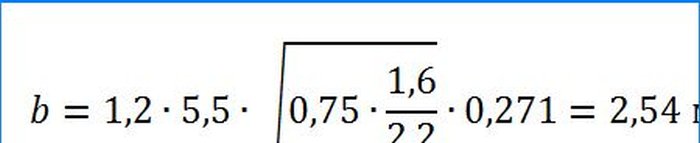

We take the wall thickness of the aboveground part – 1.65 m.Using the same formula, we find the wall width along the base of the foundation.

1.2 – coefficient of reliability for the foundation.

We accept the retaining wall with preliminary dimensions according to the calculation with a section of 1.65×2.54 m from concrete of class B15.

Sequence of work

Before the installation of a monolithic concrete wall, concrete preparation is arranged under its sole. Its thickness is 100 mm. Along the entire perimeter, the preparation should be 150 mm wider than the wall. Concrete class not less than B5.

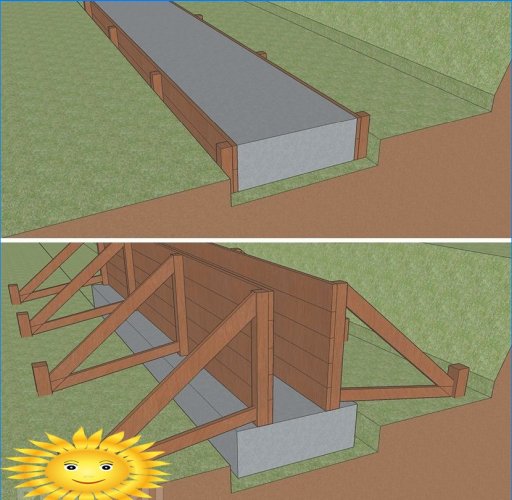

Formwork

The formwork for the retaining wall is mounted from an edged board of deciduous (birch, beech, linden, alder) and coniferous (spruce, pine) species. Planks with a width of no more than 15 cm are used. The moisture content of the tree for formwork is allowed no more than 25%. All wooden elements are impregnated with antiseptics.

Shields are hammered from the boards, which are supported by struts or struts every 70–100 cm. You can also use inventory formwork. For this, the dimensions of the retaining wall are selected in accordance with its dimensions..

Production of concrete mix

The concrete mixture for class B15 (M200) is prepared in the proportion – cement: sand: crushed stone (gravel):

- 1: 3: 4.75 (by weight);

- 1: 2.25: 4.1 (by volume).

1 m3 concrete is taken 155 liters of water and 250 kg of cement M400. A concrete mixer is used to prepare the mixture..

Concrete placement

Before the start of concreting, the correctness of the form and installation of the formwork is checked. Further, the inner surface of the formwork is cleaned of dirt and debris. Wooden elements are moistened with water an hour before concreting.

Concrete compaction

The concrete mix is laid in layers of 20–30 cm. Each layer must be compacted with hand rammers or a deep vibrator. The best conditions for concrete hardening are created during continuous concreting of the entire structure.

A short break in work, when the concrete is in the initial stage of hardening and has a certain mobility, will not affect the strength of the entire structure. In this case, you can continue concrete work without additional measures..

If the concrete already loses its mobility and gains strength, it is necessary to clean the surface of the previously laid concrete from the cement film, make notches and preferably blow it out with compressed air. Next, a thin layer of mortar is laid with a composition of cement: sand, like concrete. Then the concrete is placed in the usual manner..

Curing

In summer, in dry hot weather, the concrete surface is protected from overheating and wind. To do this, cover it with wet sawdust, matting or plastic wrap..

To avoid quick drying of the surface, the concrete is watered for a week. At a temperature of more than 15 ° C, concrete is watered every three hours during the first three days, then at least three times a day.

In cold weather at temperatures less than 5 ° C, the surface of hardening concrete is covered with heat-insulating materials.

Stripping

For retaining walls, the removal of the formwork is possible only when the concrete has reached 100% strength. The easiest way to determine if the formwork is possible is to tap the finished concrete with a hammer. When gaining sufficient strength, the structure emits a sonorous sound.

After removing the formwork, backfilling is performed with sand, gravel or crushed stone with layer-by-layer compaction.

If the length of the retaining wall exceeds 10 m, a temperature-sedimentary seam is required. It is made to the full height of the structure. Inhomogeneous soil under the foot of the structure can create stress in the wall and therefore the expansion joint is made in places where soils with different properties are separated. Resin boards with a thickness of at least 3 cm are installed in the seams.

The surface of the retaining wall in contact with the ground must be protected with paint waterproofing, mastics or bituminous solutions.

With a large slope of the personal plot, the retaining wall solves the issue of its leveling, and can also be an excellent option for landscape design.

What are some common devices and technologies used in building retaining walls on sites? Additionally, is there a way for a beginner to calculate the dimensions and materials needed for a do-it-yourself retaining wall project?

Can you provide more information about the device technology used for retaining walls on construction sites? Additionally, could you offer guidance or resources for calculating the measurements and requirements for building a retaining wall on my own?