Recommendation points

- Film and fabric: what is in common

- Variety of colors and patterns

- Strength and durability

- All about ecology and sanitation

- Installation details

- Practicality, cleaning, care

As you know, stretch ceilings are of film and fabric types, but the difference between them is less obvious than it seems. We will tell you how to choose a type of stretch ceiling according to the type of room and operating conditions, as well as compare the main characteristics of both materials.

Film and fabric: what is in common

Fabric and PVC stretch ceilings have a fairly wide range of differences in practicality of use and purely technical ones. However, before proceeding to their description, it is worth clarifying some common features of both types..

First of all, any stretch ceilings have all the advantages of suspended systems. They allow you to avoid a rather time-consuming leveling with plaster, which tends to flake and crack. And, of course, there is the most important opportunity to freely spread communications along the ceiling, starting from electrical wiring and ending with ventilation ducts.

By design, both types of ceilings are also similar: an installation profile is always used, in which the edges of the stretched canvas are attached. Due to the elasticity of materials, the ceiling is not afraid of impacts and all kinds of mechanical influences, with the exception of punctures and cuts. The general advantages can also be attributed to a very technological abutment to the walls, which does not require additional installation of moldings.

In use, both materials behave excellently:

- do not collect dust;

- easy to clean;

- do not require re-staining.

The common feature for both types of stretch ceilings is the limitation of the maximum web width – from 4 to 5 meters, depending on the manufacturer. The seams and adhesions of wider canvases can only be noticed upon close examination, however, their location should be consistent with the axis of symmetry of the room..

Variety of colors and patterns

Although both fabric and film offer a wide variety of colors and patterns, each material has its own conceptual differences. Fabric ceilings can be attributed to more restrained coatings: pastel colors prevail in the palette, and elegant floral and vintage ornaments are the most popular of the patterns. The fabric is mainly chosen with the classic interior styling, complementing the appearance with stucco or cornices.

Due to the peculiarities of the production process and the structure of the material, film ceilings have a richer spectrum of colors and textures, including bright and saturated colors. The film can be either glossy or matte or semi-matte, there are much more variations here than in fabrics that never have a glossy finish. The degree of transparency of the film is adjusted, you can use a huge number of different methods of illumination, for example, LEDs.

For both coatings, it is possible to apply photo printing of varying degrees of complexity. However, on PVC film, the pattern will be more saturated and detailed, while prints on fabric canvas are predominantly more modest. An important feature of the fabric is the possibility of its decoration after installation using acrylic paints.

It is also worth noting that PVC film is not produced purely white, there is always a shift towards some pastel shade. At the same time, the fabric ceiling can have an ideal whiteness, which does not dazzle due to the rough micro texture of the material.

Strength and durability

The presence of a tissue base plays a critical role in ensuring resistance to mechanical stress. Although both types of ceilings perfectly tolerate an evenly distributed load, fabric ceilings are somewhat superior to film ceilings in resistance to various kinds of damage. The fact that both materials are capable of holding about half a ton of water is known to many, and this is true, although it all depends on the reliability of the fastening of the canvas in the baguette profile.

Although tissue resistance to damage is higher, including to sharp objects, experiments are not worth carrying out. The film bursts from the slightest puncture due to strong tension, the fabric can also, but the likelihood of this is lower due to the low tension of the material and the presence of a reinforcing base.

Thermal exposure is much more important. Elevated temperatures do not harm the material, but the ceiling may sag until the temperature is restored. Permanent heating does not affect the film in the best way: in the places where spotlights are installed, the material can change color and become brittle from drying out.

Fabric canvases are made non-combustible and resistant to open flames. It is also important that the fabric tolerates low temperatures well, while PVC film, when cooled to negative temperatures, can simply crumble.

All about ecology and sanitation

Both the fabric and the film are positioned as absolutely environmentally friendly materials that are not capable of harming health. In the case of fabric, this is indeed the case: both the base and the impregnation are chemically inert and do not form residual emissions. But the safety of the film in some cases can be called into question.

First of all, because PVC has a slight odor emission in the first day or two after installation. And although in the ordinary case this is simply expressed in an unpleasant odor, sometimes the individual intolerance of polymer particles comes into play. We emphasize, however, that these are quite rare exceptions to the general rule, and for the most part, the film coating does not have any effect on residents..

A significant difference for the two materials is vapor permeability. The fabric allows gas exchange with the area behind the decorative cover, while the film completely blocks air and water vapor inside the room. This should be taken into account when finishing buildings with complex insulation systems that require free exit of moist air through the enclosing structures.

Installation details

Film ceilings can be classified as products that require a minimum degree of participation from the customer. Preparation of the canvas at all stages: measuring, soldering, gluing the mounting flange and making holes for spotlights – completely and completely takes place in the manufacturer’s workshop. Each film ceiling is made according to an individual order.

The product arrives at the facility in a completely finished form. Installation takes only a few hours: while the room and the film are warming up, the baguette profile is attached, then the heated and stretched canvas is fixed in it. For this period, the presence of residents, their pets, plants and furniture in the room is undesirable..

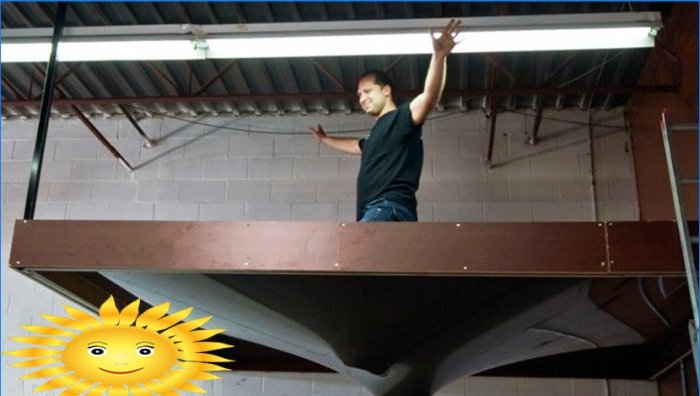

Fabric ceilings do not require special installation equipment. The fastening profile has a slightly different structure, and the strength of fixing the fabric in it is slightly lower than that of the foil ceiling locks. This plays a role in retaining additional mass, such as when flooding from above, but both systems do a great job with web tension.

The fabric is fixed by threading the edges into the narrow groove of the baguette profile using a special rounded spatula. Additional devices are not required, therefore, with proper skill, the layman can cope with the installation of a fabric stretch ceiling.

Practicality, cleaning, care

Both fabric and film ceilings do not cause any problems in operation. The characteristics of the materials ensure the durability of the finish, measured in tens of years. At the same time, the surfaces are resistant to fading and loss of strength properties, if desired, they can be easily and quickly replaced in case of damage or in order to update the interior.

Ceilings do not require cleaning as such, although they are, of course, not insured against pollution. In rare cases, cleaning the film ceiling is carried out using ordinary soapy water, although ideally it is recommended to use a special chemistry that does not leave a sticky coating on which dust will collect.

Fabric ceilings do not take wet cleaning very well: after getting wet, streaks and darkening may appear on a canvas with a perfectly uniform color. For cleaning, it is advisable to use special brushes for vacuum cleaners, which are also applicable when caring for film ceilings.

Which material, PVC or fabric, would be the better choice for a stretch ceiling in terms of durability, maintenance, and overall performance? And what are some important factors to consider when it comes to the operation and long-term use of these materials for a stretch ceiling installation?