Recommendation points

- Service of coarse air filters

- Fine air filters

- Cleaning the external block of the split system

- Split system prevention

- Four main causes of split compressor malfunction

- At the end

In this Article: Self-Service Coarse Filters fine air filters – replaceable and renewable; the most common causes of compressor breakdown in a split system and how to avoid them.

Compared to other types of household appliances, air conditioning systems are physically unable to operate without service, and with a strictly defined frequency. If you expected to purchase a split system, pay for its installation and from that moment on to provide optimal climatic conditions in your house for many years by lightly touching the buttons on the remote control, this is a delusion. Consider the types of preventive work required for air conditioning units – some of them are simple and performed by the owners, but some of the work can only be performed by specialists.

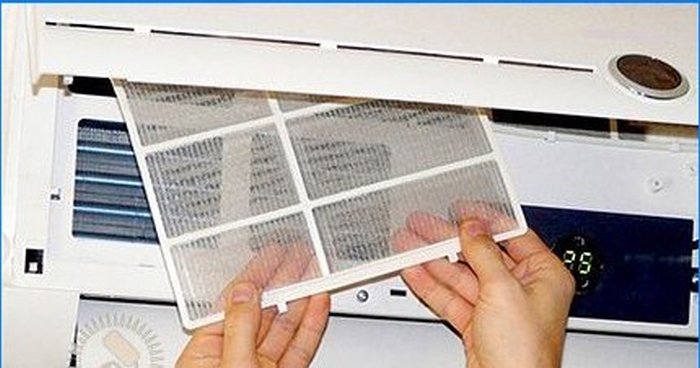

Service of coarse air filters

The first line of defense of the indoor unit of a split system from dust suspended in the air is coarse air filters installed in front of the radiator-evaporator. Depending on the length of the hairdryer, there can be from one to three such filters. The coarse air filter consists of a lattice plastic frame, in which several layers of a fine fine mesh are fixed. The task of this filter is to block access to the evaporator of dust and other coarse particles suspended in the atmosphere of the room.

During the operation of the split system, air is pumped into the indoor unit by the ventilation unit, dust particles settle on the filter, eventually forming a rather dense and thick layer over its entire area, reminiscent of felt. If the filter has not been cleaned for a long time, then the dust “felt” will successfully block the flow of air into the air conditioner, forcing the fan to work at maximum load and wear..

How will the internal split unit behave when the filter is clogged with dust? The first sign is a weak flow of conditioned air produced by the device even when the turbo mode is set. Due to insufficient blowing of the radiator-evaporator, the refrigeration cycle of the split system will be disrupted. the refrigerant entering it does not go into a gaseous state (does not evaporate) due to the lack of warm air, which will cause the freon line to freeze and may lead to compressor breakdown. A typical sign of frozen copper pipes is that after turning off the air conditioner, drops of water flow out of the hairdryer, caused by the thawing of ice formed from condensate deposited on the frostbitten pipes. In more advanced cases, dense lumps of dusty “felt”, which is not able to hold onto the filter, will fall into the condensate container and clog the drain pipe – the container will overflow with liquid, and water will flow from the hair dryer onto the floor. The last argument in favor of regular filter cleaning: a wet dust layer creates ideal conditions for the development of dissimilar microorganisms, i.e. a split with a clogged filter not only does not protect its owners from viruses, quite the opposite – effectively promotes their spread in the room atmosphere.

How do I clean the air filter? The hardest part of this operation is finding a suitable chair or ladder to reach the indoor unit with your hands. So, we stand on a chair, with our fingers grasp the lid on the block on its two sides, gently slide both edges of the lid towards ourselves, then lift it up – the lid will easily slide and lock in the “open” position. Coarse filters are located immediately behind the cover – to remove them, you need to pull on the tab at the bottom of the filter, sliding up and freeing the plastic frame from the groove in the indoor unit housing. Then you just need to pull out and remove the filter – try not to shake it. Then you need to remove the dust layer with a vacuum cleaner or a stream of tap water (you can use non-abrasive detergents and a brush), in the second case, the filter must be air-dried in the shade – heating devices cannot be used to speed up drying!

Until you install the cleaned filter back into the split system, you should not turn on the air conditioner – the radiator-evaporator will become dusty.

Installing the air filter is as simple as removing it: wind its top along and up the evaporator; then insert the lower part into the block groove; with a slight effort of two hands, lower the cover, pressing the edges against the block body until it is fixed in this position. By the way, the cover of the hairdryer can also be removed and washed with water and detergents (not abrasive) – it is removed from the grooves located on the two upper sides of the indoor unit.

How often should the coarse filters of the air conditioner be cleaned? The frequency of cleaning depends on a number of factors – the intensity of movement of people through a given room, the frequency of cleaning, the presence of carpets, the proximity of busy streets to the house, air humidity, etc. The exact frequency is determined experimentally, by examining the condition of the filter, however, this operation must be performed at least once a month or two during the period of active use of the split system.

Fine air filters

If plastic mesh filters for coarse air purification in split systems are capable of serving indefinitely, fine filters are more complex and therefore serve only a certain period. Consider the possibility of cleaning and the frequency of replacement of such filters:

- The adsorbent carbon filter cannot be cleaned, it needs to be changed every 4 months;

- The adsorbing zeolite (photocatalytic) filter allows cleaning in a container with warm soapy water for an hour, then it must be dried for 4 hours and always in the sun – ultraviolet light will break down organic pollutants accumulated in it. A complete replacement must be done every 5 years;

- the plasma (ionizing, electrostatic) filter, which attracts and destroys organic pollutants, does not require replacement during the entire service life of the split – it is enough to clean it with a household vacuum cleaner once every 6 months;

- the catechin antibacterial filter can be washed under water, followed by drying in the shade, the frequency of replacement with a new one depends on the intensity of cleaning – the more often you need to wash it, the faster you need to change it to a new one. On average, the antibacterial filter needs to be changed every six months..

Cleaning the external block of the split system

The dust, present in the external atmosphere almost all year round, enters the inside of the street split-block and is deposited on the units contained in it, and what is especially bad – on the condenser radiator. If it is not cleaned for several years in a row, the performance of the air conditioner will seriously decrease due to insufficient heat removal from the air conditioning system.

The owner of the split will not be able to remove dust deposits from the external block on his own, it is necessary to involve specialists, however, representatives of this profession can take money from you, and the prevention is not really carried out. How should the external block of the split system be cleaned correctly? It is possible to completely remove dust from the street block in only one way – with special brushes, accompanied by the cleaning process with a constant supply of compressed air to this area of work. Often, representatives of the preventive service flood the switched off split-block with several buckets of water or use a pressure washer – similar devices are used for washing cars. Both options are ineffective, and the latter is even dangerous – a powerful jet of water can easily bend the condenser fins, which the owner will not even know about, and the “experts” will explain the drop in the performance of the air conditioner after such cleaning by the development of a resource, difficult climatic conditions, etc..

It is recommended to completely clean the street block of the split system at least once every 2 years and once a year – with year-round use of the air conditioner.

Split system prevention

Every year the freon circuit of a two-unit air conditioner loses up to 8% of the refrigerant, and these losses are within the normal range, i.e. are quite common with a well-executed split installation. The reason lies in the particular connection of copper pipes that unite the indoor and outdoor units with each other – it is impossible to connect flared pipes to the fittings of the split-blocks in such a way that there is no leakage at all.

Failure to refuel, at least once every two years, will lead to a decrease and, over time, a complete loss of cold performance in this air conditioning unit. If the cooling capacity drops, the compressor breakdown is inevitable. during operation, this unit, which is extremely necessary for any refrigeration system, overheats and it is freon that cools it – if there is not enough freon, then there will be no compressor cooling. An overheated compressor will jam, it will need to be replaced, and the cost of this unit is 40–45% of the price of the entire split system.

During a visual inspection of the outdoor unit with the casing removed, you can immediately understand that there is not enough refrigerant – frost and partial icing are observed in the area of connection of the fittings and copper pipes of the device that was operating before the inspection. Measurement of operating temperatures at the inlet and outlet of the freon line in the external unit will help to confirm suspicions – the difference between them must be at least 8 ° С.

Four main causes of split compressor malfunction

Leading in this list is poorly performed installation – lack of vacuumization, violations in the construction of the freon circuit, leaking choke connections, low-quality processing of copper pipes during their expansion.

The vacuumization technique is described in the previous part of the article, if you ignore it or perform it somehow, air and moisture will remain in the refrigeration circuit, which usually leads to a breakdown of the compressor motor winding. Air and water will cause even more harm if the freon line is charged with modern refrigerants such as R410A – polyester oil used in systems with such freons perfectly absorbs moisture, which changes its performance. As a result, the quality of the compressor lubrication decreases, it is jammed..

A number of irregularities in the construction of the refrigeration circuit – ignoring slopes and oil-lifting loops, pipe breaks, too short or excessive pipeline length, etc. – also reduce the quality of the compressor lubrication, which leads to its seizure and complete failure.

The mediocre quality of the connection of flared copper pipes with the compressor unions, as already mentioned, will cause large losses of refrigerant and, as a result, overheating of the compressor.

Another reason for the malfunction of the “heart” of the air conditioner, arising from poorly performed installation work, is the penetration of solid particles into the refrigerating circuit – copper chips, fragments of flux and solder.

Choose the installation team carefully who will install the air conditioner!

In second place is the complete disregard of the operating conditions of climatic devices given in the instructions by the owners of split systems. Most often, counting on chance, the lower temperature limit for reversible splits is not observed – the unit turns on at low outdoor temperatures, for which it is not designed. Contrary to simple logic, the compressor does not cool down at temperatures outside the window below zero, but heats up even more, since the atmospheric cold reduces the density of the refrigerant, therefore, less freon is supplied to the compressor than necessary. And since it is freon that cools the compressor, the latter overheats and inevitably fails.

In addition, attempts to heat the room using a split at low temperatures outside the house are likely to cause a water hammer, hitting the compressor and disabling the unit. The reason for the water hammer in the refrigeration circuit of the air conditioner is as follows – liquid freon, which has not evaporated due to low outdoor temperatures, enters the valve system of the line supplying refrigerant from the indoor unit.

In the cold season, serious damage to the units of the outdoor unit is caused by the ice formed on them. A layer of ice growing on the compressor radiator breaks the blades of the ventilation unit, and when ice builds up on the blades, their rotation becomes difficult or completely blocked, as a result of which the fan motor burns out..

Do not turn on the split system at outdoor temperatures, the level of which is close and, moreover, equal to that specified in the instructions for the device.!

The third place among the reasons for the breakdown of the compressor of the split system is occupied by dubious quality components, first of all – low-quality copper pipes. It is extremely difficult to detect a defect in a copper pipe not only at the installation stage, but also after its completion..

You should not try to save on components by using cheaper analogs of unknown origin! Must only be purchased from specialized and well-known suppliers.

In the last place is the factory defect of the compressors. Large manufacturers will not allow their products to pass inspection at an inappropriate level, because this affects the “face of the company”, so the scrap rate among compressors produced under well-known brands is close to zero. Low-quality units are found in split systems of little-known brands assembled in third world countries.

By purchasing a cheap but doubtful compressor as part of a split system or separately, you run the risk of spending your money twice – the first time to buy and pay for the installation of a cheap unit, and the second time to purchase a branded model with dismantling the previous compressor and paying for the installation of a new one..

At the end

Preventive maintenance is not required for the refrigerator and monoblock air conditioner, window or mobile – their circuit is assembled at the factory, so there is no loss of freon from the system. You cannot say the same about split systems, because they need to pump freon of a certain brand, and without fail. Attempts to save money on maintenance will lead to only one thing – the air conditioning system will fail and it can be restored only for a much larger amount, because replacing a compressor is never cheap.

The next material from the cycle “about climate systems” is devoted to diseases, one way or another associated with air conditioning systems and methods of preventive protection against them.

Can you provide any tips or recommendations for the selection, installation, and operation of split systems? I’m particularly interested in any important considerations or potential challenges to be aware of during these processes. Thank you!

When selecting a split system, consider the size of the area you want to cool or heat, as well as the energy efficiency rating of the unit. It’s important to select a system that is properly sized for the space to ensure optimal performance. Also, make sure to hire a reputable HVAC professional for the installation to ensure it is done correctly.

During installation, consider the placement of both the indoor and outdoor units. The indoor unit should be placed in a location that allows for proper airflow and distribution of air, while the outdoor unit should be placed in an area with plenty of ventilation and free of obstructions. Additionally, make sure to properly insulate any tubing or wiring to prevent energy loss.

For operation, regularly clean or replace the filters to maintain efficiency and airflow. Also, consider investing in a programmable thermostat to optimize energy savings. Keep an eye out for any unusual noises or performance issues, and address them promptly to prevent larger problems down the road.

Overall, the key to a successful split system installation and operation is proper planning, professional installation, and regular maintenance. By following these tips, you can enjoy efficient and effective climate control in your space.

What are the key considerations to keep in mind when selecting, installing, and operating split systems?

When selecting, installing, and operating split systems, there are several key considerations to keep in mind.

Firstly, it’s crucial to consider the size and layout of the area to be cooled or heated. Choosing the correct capacity of the split system is essential to ensure optimal performance and energy efficiency.

Secondly, the location of the indoor and outdoor units should be carefully chosen during installation. The indoor unit should be placed in a spot that allows for efficient air distribution, while the outdoor unit should have adequate space for proper ventilation and maintenance access.

Additionally, considering the energy efficiency of the split system is important. Look for systems with high energy efficiency ratings and features like inverter technology that can save on energy consumption and utility costs.

Proper maintenance and regular cleaning of the filters, coils, and drainage system should be done to ensure the efficient operation of the split system. It’s also important to follow the manufacturer’s instructions for operation and maintenance to prolong the lifespan of the unit and avoid potential issues.

Lastly, it’s advisable to seek professional installation and periodic servicing to ensure safe and effective operation of the split system. This will not only optimize its performance but also provide peace of mind.

When selecting, installing, and operating split systems, there are several key considerations to keep in mind. Firstly, make sure to choose the right size unit for the space you are trying to cool or heat. An undersized unit will not effectively regulate the temperature, while an oversized unit can lead to energy inefficiency and uneven cooling.

Secondly, ensure that the split system is installed by a qualified technician. Proper installation is crucial for the system to function efficiently and prevent any potential issues in the future.

Additionally, consider the maintenance requirements of the split system. Regular cleaning and servicing are essential to ensure optimal performance and longevity of the unit.

Lastly, familiarize yourself with the operating instructions and settings of the split system. Understanding how to use the system efficiently can help save energy and ensure a comfortable indoor environment. Remember to regularly check for any strange noises, leaks, or odors, as these may indicate a problem that requires professional attention.