Foil insulation refers to combined materials. This is, in fact, the insulation itself, covered with polished foil. Our advice site will tell you what kind of foil heaters are, where they are used, providing high quality thermal insulation due to its properties.

According to the type of heat-insulating material and the density of the polished foil, all foil-clad heaters are divided into the following types.

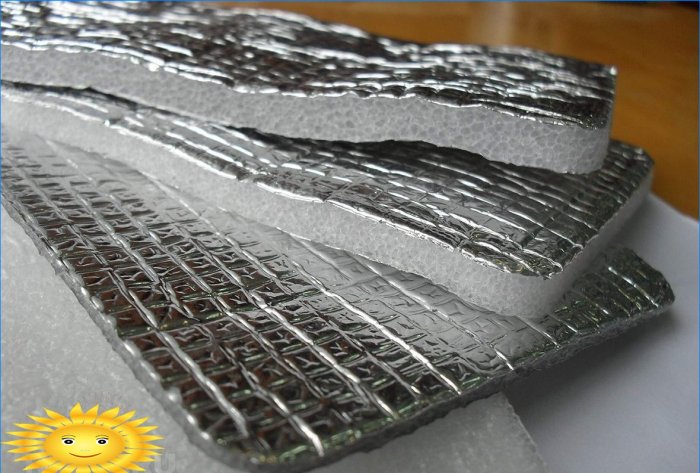

Inexpensive thin roll insulation. This is penofol, about which the portal wrote in detail. Other names for this type of insulation are izolon and folgoizol. The thickness of the foil-clad heaters is from 2 to 10 millimeters, the directly heat-insulating material is foamed cross-linked or non-cross-linked polyethylene. Sometimes the insulation is produced with a self-adhesive base. Water vapor permeability – 0.001 mg / (m · h · Pa), moisture absorption – only 0.35-0.7%.

Roll foil insulation materials are used for thermal insulation of pipes – it is convenient to wrap them around uneven surfaces and parts. In addition, penofol can be used to insulate a room from the inside, to be used to insulate loggias and balconies, as well as when arranging a warm floor and split systems. Often rolled insulation is used as an insulating substrate for laminate, parquet, and other finishing flooring.

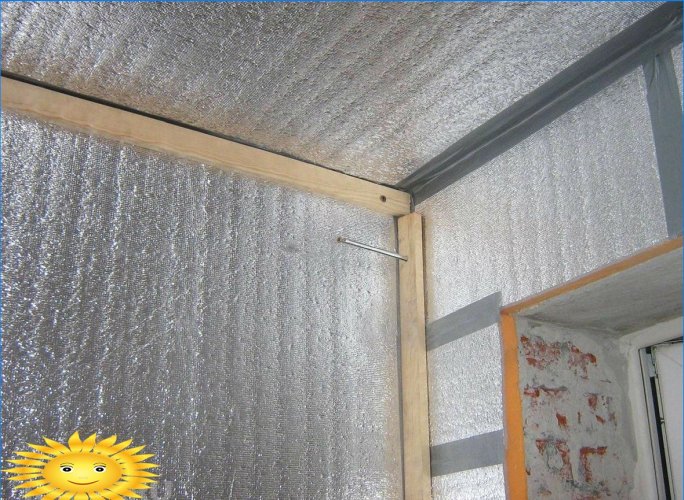

Mineral wool with foil.Familiar to many and very popular insulation, supplemented with a layer of foil. Such mineral wool, depending on the thickness, can also be sold in rolls, as well as in slabs. There are special cylinders made of foil basalt wool for insulation of chimneys.

The scope of application of foil mineral wool is wide – walls, floor, ceiling, roof structure, chimneys.

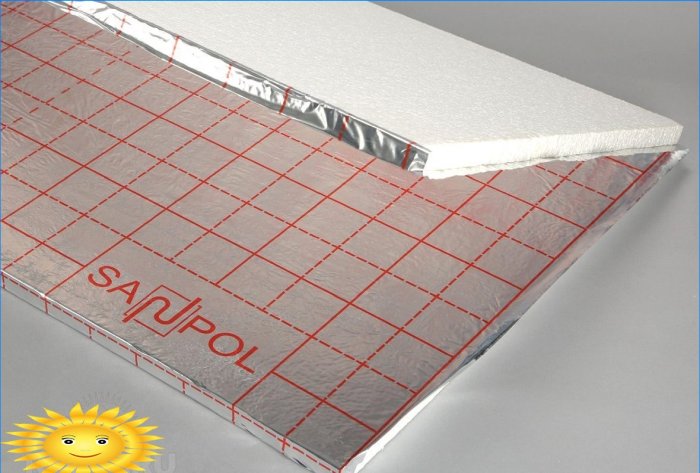

Foil polystyrene or expanded polystyrene.It is used exclusively for arranging a warm floor. There are always markings on the inside to properly lay the cable system. Thickness from 30 to 50 millimeters, standard width – 50 centimeters, density from 30 to 50 kg / m3.

Basalt heat insulator.Due to its ability to withstand temperatures from -200 to +700 C ° and aggressive operating conditions, it is widely used in the construction of various industrial and industrial buildings, including gas stations.

All of the listed foil heaters have a thermal conductivity of 0.037 W / (m ° C), a high level of vapor permeability, environmentally friendly, have a long service life – as the manufacturers say, up to 95 years.

The advantages of foil insulation are obvious:

- The scope is very wide.

- Installation is easy.

- They are protected from moisture, sunlight, last longer than usual.

- Additionally have soundproofing properties.

- They are relatively inexpensive.

- Allow to significantly improve the energy efficiency of the house, reduce heat loss.

Foil insulation also has a number of disadvantages:

- They are soft, cannot be used under finishing with building mixtures.

- The layer of rolled insulation is small, they cannot provide full thermal insulation. Therefore, they are often combined with conventional insulation..

- Sometimes special glue is required for installation, and this is an additional cost.

The main rule for installing foil insulation is that the metal, shiny side is always directed towards the inside of the room! The material does not overlap, and the joints are reliably glued with construction tape. There should be a small air gap between the insulation and the finish.

Video about the installation of foil insulation

What are the different types of foil insulation available in the market? How do they differ in terms of features and functionality?