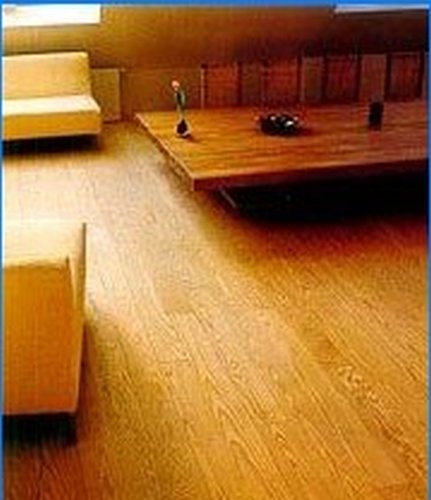

Solid wood is the progenitor of all modern wood flooring. Where else were there art parquet floors when the floorboard “fell at my feet.” And in recent years, the “Cinderella story” has happened to her. More recently, the board was used as floor coverings in the construction of the cheapest uncomplicated structures, for example, barracks, country houses, summer camps, sports halls. In city apartments, the boards were covered with parquet and linoleum, or even removed and thrown away. But the board took revenge and returned home. Now from the West and as an elite floor covering.

Solid wood is a solid (non-glued) solid wood board. (Not to be confused with a parquet board with three layers rigidly glued together). It differs from its former counterparts in the quality of wood drying, manufacturing and the fact that it is now made mainly from wood of valuable species. In addition, it now has grooves and ridges at the edges (as well as parquet and parquet boards). This allows the floorboards to be joined tightly. In other words, modern solid wood is a return to the old wooden floor, but on a new technological basis..

Nature has provided this material with a number of advantages. Wood is an excellent heat insulator, it is lightweight, has high strength and elasticity. Due to its density, the material is able to hold metal fasteners. But along with the advantages, wood also has disadvantages. The properties of wood differ significantly along and across the grain. Structural defects are highly dependent on the place of origin of the plant. And the most controversial property of wood is hygroscopicity. On the one hand, by absorbing and releasing air vapors, wood is able to regulate the humidity of the environment within the limits favorable for humans. But on the other hand, the ability to swell leads to moisture deformations, and even to decay. In heated rooms, wood dries out and warps. Too dry, it burns easily, therefore fire hazard.

The listed properties are different not only for different types of wood, but can differ significantly within the same species and even within one tree. In general, wood species containing natural oils are considered the most resistant to changes in temperature and humidity: oak, teak, merbau, dussia, iroko. Most of light woods and fruit woods (cherry, sweet cherry, pear) are among the “capricious” ones. Those who choose a solid board made of “capricious” wood species should strictly control the air humidity in the room (it is desirable to maintain it at 40-50%) and not be zealous with heaters. The most commonly used are pine, larch, oak, ash, maple, beech, birch, rosewood.

In terms of size, a massive board can be different: in length from 0.5 to 3 meters, in width from 10 to 15 cm. As for the thickness, in this case there are no strict standards, but the most popular one is considered to be 20-22 mm. The thickness of the board is directly related to its mechanical strength. In other words, it depends on how much it will bend..

There is no GOST on a massive board. Modern requirements for its quality have become somewhat different, much more stringent. This is why large manufacturers sort by their own criteria. Quality standards include, as a rule, such indicators as the type of cut radial and tangential (mixed), the permissible percentage of warping, the presence of blind cracks, knots and blue, resin pockets. This is not easy for an inexperienced buyer to understand. Therefore, we advise you to buy material from large sellers and manufacturers that have proven themselves on the market. A certain criterion when choosing is the price of the product, the higher it is, the higher the quality. Sellers admit that solid flooring is a problem product. The buyer is confused by the different lengths, the complexity of the visual identification of the variety, the considerable price. We have to explain that natural wood cannot be approached with the same measurements as laminate. This is living matter, knots, hints, rings, and stains are inevitable on it. They are here as organic and individual as a person’s fate lines in the palm of his hand.

It makes no sense to talk about the average price, because the price range is too wide. The cheapest solid board is found in a domestic manufacturer from $ 30 per 1 sq. m. Below this price range, you cannot count on quality. Obninsk Parquet Plant sells oak for $ 49, $ 34, $ 59, $ 42 per 1 sq. m, ash $ 67, $ 57 per sq. m, beech $ 62, $ 42 per sq. m. For the British ROYAL WOODKRAFT, for example, oak, depending on the grade, costs $ 59, $ 77, $ 119 per sq.m., maple $ 75, $ 95, $ 149 per sq.m., beech $ 72, $ 111 per sq.m. The German NOLTE has 1 sq. m of maple board costs $ 137, mahogany – $ 141, merbau $ 111. And, for example, a wenge tree from Zaire at the Russian MATIMEX reaches $ 228 per sq. m.

Solid planks should be installed in rooms that meet the technical requirements for natural wood flooring. She needs to undergo acclimatization in the room where it will be mounted for at least three days. The moisture content of the wood should be 8-10%. Floor coverings are laid at the final stage of the renovation, when windows and door frames have already been installed, ceilings, walls and, of course, the screed are properly leveled and properly dried. The laying of ceramic tiles must be completed as it is a wet process.

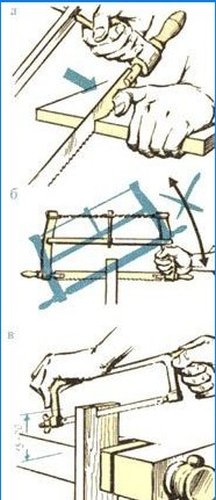

Naturally, so that later there will be no problems with a beautiful and expensive floor covering, it is necessary to correctly and carefully prepare the base for it. There are several ways to build the base. The appropriate option is selected depending on the type of floors in the house, desires and material capabilities of the customer. A massive board can be laid on reinforced concrete floors: on a screed and logs, on a screed and plywood; on logs and plywood without filling the screed; on adjustable plywood. On wooden and mixed floors, it is laid on logs and plywood, on logs and slabs of chipboard, fiberboard.

Each manufacturer has its own ways of fixing a solid board. For example, metal staples. The boards are not glued to the base, but only fastened together with staples, which are inserted into the longitudinal grooves of the board. With a change in the moisture content of the base or its deformation (which happens in newly built country houses, when the structure gives a draft), the solid board remains independent of these fluctuations. The floor covering laid in a “floating” way allows the massive board to “breathe”, leaving it with the opportunity to slightly change its dimensions along with changing external conditions.

To give perfect evenness, it is recommended to sand the board. Then, if in the factory, even during production, no coating is applied, it is coated, if desired, with a tinting composition, varnish. And recently, with the fashion for everything natural and ancient, they began to use oil and wax. Such a board has a number of advantages, primarily from an environmental point of view, especially if there are allergies in the house..

Even on a perfectly laid high quality solid board, gaps will still appear over time. This is the result of the natural movement of wood. Experts believe that there is nothing wrong with that. After all, this is precisely the aesthetics of a solid board. The Germans, for example, believe that the appearance of cracks is an integral part of a good natural floor. In Russia, however, they are still more wary of this phenomenon. And although it is almost impossible to avoid the appearance of cracks, you should at least know that in our climate, especially in winter, the conditions for wood are simply critical. In the apartments, heating batteries are working with might and main, there are sealed plastic windows in the windows, air conditioners, as a rule, do not work. As a result, the air humidity drops below 30% and even 20%, while its optimal indicator is 40-50%. Therefore, in order to avoid drying out of the massive board, it is imperative to put a humidifier in the room.

In any case, when purchasing a solid board, you are buying a “living” tree, on which there may be small knots and small cracks, but they only emphasize the sophistication and nobility of this material. It is not for nothing that today it is a solid board that is rightfully considered the most elite flooring made of wood.

What does the phrase “massive board underfoot” refer to? Is it a literal board or a metaphor?

What is the purpose or function of the massive board mentioned? Is it meant for a specific activity or used in a particular industry?