Recommendation points

Is there an easy way to decorate the facade “antique” with rusticated plaster? How to lighten the elements of massive decor and perform such a finish along with insulation? In this article you will find answers to questions and learn about different methods of manufacturing elements of a volumetric facade.

In the articles “History and varieties of rusticated plaster” and “We create a massive rusticated facade with our own hands: the first method is classic” we described that the old way of rusticating the facade, with all its advantages, has a number of disadvantages:

- Labor intensity. Thorough broaching (cutting, squeezing) of each rust is a painstaking task.

- High cost. The use of modern lightweight solutions will reduce labor intensity, but add to the cost.

- The method does not allow to fully insulate the building (or the depth of the rust should be no more than 20 mm with a lightweight solution).

- High professionalism is required when creating complex elements – cornices, corners, arches and openings.

Only these four points are enough to abandon the idea of a massive facade. However, there is a way out that will allow you to achieve the desired result in appearance, having fulfilled the standard for insulation and without ruining the owner of the house.

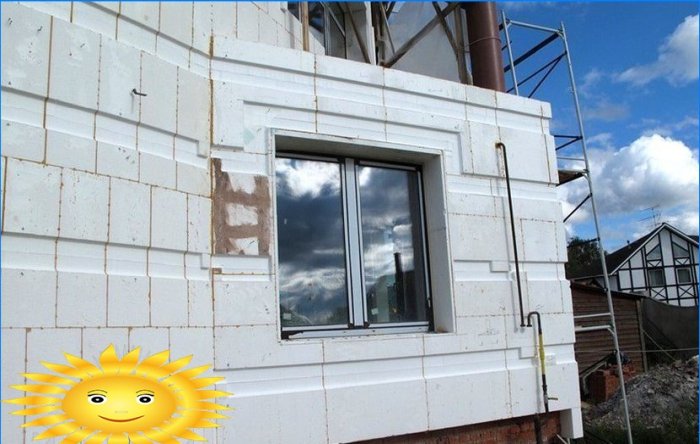

This method is simple, like everything ingenious. The material of the quadra is insulation – ordinary or extruded penepolystyrene (hereinafter – PP). As we found out in the article “Artificial or natural insulation: which one to choose”, PP is very easy to process, while, due to its properties, it keeps its shape perfectly and does not deform over time. It is this property of expanded polystyrene that makes it possible to modernize the classical method of creating a massive rusticated facade.

There are four main options for exterior decoration using PP boards.

Option one. Overlay

Squares are cut on the ground (on a machine) and mounted on an umbrella dowel to the wall.

Operating procedure.

- On the first layer of insulation, mark the squares, arch corners and other elements of the ornament according to the project and sketches.

- It is desirable that the first layer of insulation be completely covered with a reinforcing composition with a mesh. However, you can save money here: apply the composition with a grid only along the markings (stripes). Then the markup will have to be applied again – on the dried glue.

- We cut quadras from PP of the required thickness, parts of corners and other elements.

- We mount the elements according to the marking on the dowel-nail, foam or glue.

- We cover the quadras with a reinforcing compound with a mesh.

- We apply finishing layers (putty, painting).

This method has a number of distinctive features..

Advantages:

- Allows you to correct mistakes – you can always cut another quadra.

- It is possible (with a certain skill) to quite accurately cut out composite and combined elements of complex shapes – letters, logos, bas-reliefs.

- Quadra thickness – up to 100 mm (corresponding to the PP thickness).

- Allows you to create multi-level relief.

- Can be used on any insulation (cotton wool, PP) or wall.

Disadvantages:

- Requires careful preparation “on the ground” – the device of the machine and cutting devices.

- With manual pruning in place, only simple types of rust will be obtained – rectangular, triangular and prismatic.

- A large percentage of waste is possible.

Council. When choosing this method, proceed in the calculations of the squares from the sheet size in order to avoid a large number of scraps..

The approximate cost of the “overlay” method per 1 m2 (layered layout excluding the base insulation layer):

Material Unit rev. Unit price, rub. Consumption per m2 Price 1 m2, rub. Ceresit CT 17 primer liter 57 0.15 ten Ceresit CT 85 cement glue (25 kg) Kg 80 five 400 Expanded polystyrene Knauf Therm Facade 25 (50mm) m2 136 1 136 Glass mesh Ceresit CT-327 m2 25 1 25 Ceresit CT 85 cement glue (25 kg) Kg 80 five 400 Ceresit CT 17 primer liter 57 0.15 ten Front putty Ceresit CT 137/25 m2 36 3 110 Ceresit CT 17 primer liter 57 0.15 ten Facade paint Ceresit CT 54 (15 kg) Kg 240 0.35 84 Total material 1185 Job 800 Total material and work 2000 Option two. Slotting

Rough grooves for rustications are cut in a layer of insulation (PP) reinforced to the wall and a special rusticated profile made of plastic or aluminum is placed in them. It has a reinforcing mesh at the edges, which allows it to be incorporated into the finishing of a “wet” facade. The first layer of insulation should be calculated with a margin for the thickness of the quadra (the depth of the rust).

Operating procedure:

- We mark the plane according to the project and sketches.

- We cut rough grooves under the rustication profile, thereby highlighting the elements.

- We put the profile in the grooves. If necessary, fix with foam or glue.

- We cover the quadras with a reinforcing layer, connecting it to the profile mesh.

- Apply finishing filler and paint.

This method also has a number of features..

Advantages:

- Perfectly smooth factory-quality rustic, no painting required.

- No need to finish rustic edges.

- Large selection of rustic profiles – from straight to curly.

- Minimum amount of PP waste.

- Can be used on any insulation (PP, cotton wool).

Disadvantages:

- Slotting errors are hard to fix.

- The thickness of the quadra (depth of the rust) is limited by the dimensions of the profile (10–40 mm).

- Allows you to create only straight lines, straight-sided shapes.

- From a close distance, the method is diagnosed by the joints of the profile and the lack of coverage on it.

The price of a rustic profile is on average 60 rubles per linear meter.

The approximate cost of the slotting method per 1 m2 (layered layout excluding the base insulation layer):

Material Unit rev. Unit price, rub. Consumption per m2 Price 1 m2, rub. Ceresit CT 17 primer liter 57 0.15 ten Ceresit CT 85 cement glue (25 kg) Kg 80 five 400 Expanded polystyrene Knauf Therm Facade 25 (100 mm) m2 270 1 270 Rusting profile VWS 10-50 mm, Ukraine run. m 60 1.5 90 Glass mesh Ceresit CT-327 m2 25 1 25 Ceresit CT 85 cement glue (25 kg) Kg 80 five 400 Ceresit CT 17 primer liter 57 0.15 ten Front putty Ceresit CT 137/25 m2 36 3 110 Ceresit CT 17 primer liter 57 0.15 ten Facade paint Ceresit CT 54 (15 kg) Kg 240 0.35 84 Total material 1400 Job 800 Total material and work 2200 Option three. Combined

Rust with a depth of 10 to 30 mm is cut into panels, which serve as the main insulation. This is done using a special rustic machine – a hot cutting device that creates a smooth cut of a given shape in a sheet of expanded polystyrene. Possible option with manual cutting according to the rule using self-made devices.

Operating procedure:

- A mesh with a cell is applied to the project of the facade, the size of a PP sheet (it is convenient to use square sheets of 1 m).

- We mark and rusty the sheets (with a typewriter or manually) one by one on the ground in accordance with the resulting layout.

- We strengthen one by one per dowel-nail to the wall, observing the transition of the picture.

- Apply reinforcing and finishing layers.

Advantages:

- Optimum waste-free use of material.

- Two operations in one (no base layer of insulation needed).

- In case of error, you can use the other side of the sheet.

- Single layer technology is always better than multilayer.

Disadvantages:

- The cost of a rustic machine starts from 7 thousand rubles.

- In case of repeated error, the whole sheet is rejected.

- Relief in only one plane.

Material consumption will completely coincide with the previous option (cutting). The work will cost more – approximately 1000 rubles / m2.

Option four. Exclusive

Considering options for rusticated plaster, we came close to the stucco. This is a whole section of decor, which will require a separate article. We will only consider what relates to facade rustication. This option is not for nothing called exclusive – this work is performed exclusively by firms that have special equipment for the production of unique models – stucco elements.

The material for them is modified polystyrene foam, which includes lime, gypsum and cement. Simple unified elements of such products can be found on the free market and applied according to your own design project. But the real exclusive will be the order of turnkey works.

The order of work when doing it yourself:

- We reinforce the base layer of insulation with mesh and glue.

- We mark the location of the elements.

- On open areas (outside the stucco molding) we apply a finishing layer.

- We attach the stucco elements to special glue according to the marking.

- We close up the gaps and gaps between the base and the elements with a finishing putty.

- We paint the entire facade.

Advantages:

- Stucco elements do not require the application of protective and reinforcing layers, and must be painted.

- Due to the binder additives, modified PP can be processed more precisely.

- Does not require fastening to a dowel-nail (only special cement glue).

- Factory quality elements.

- A well-applied method cannot be diagnosed.

- Possibility to order the entire facade in the complex.

Disadvantages:

- High production cost.

- Relatively large weight (in comparison with conventional PP) – 30-40 kg / m2.

- Low prevalence of material.

Approximate cost of the method per 1 m2 (layered layout excluding the base insulation layer):

Material Unit rev. Unit price, rub. Consumption for 1 m2 Price 1 m2, rub. Ceresit CT 17 primer liter 57 0.15 8 Ceresit CT 85 cement glue (25 kg) Kg 80 1 80 Square, corner, cornice (Ledimore, “EUROPLAST”, Gaudi Decor), on average element 150 3 450 Ceresit CT 17 primer liter 57 0.15 8 Front putty Ceresit CT 137/25 m2 36 1.5 54 Ceresit CT 17 primer liter 57 0.15 8 Facade paint Ceresit CT 54 (15 kg) Kg 240 0.35 84 Total material 700 Job 1200 Total material and work 1900 Often this method is used in the restoration of architectural monuments and even the creation of sculptures. The high accuracy of modern equipment allows you to recreate whole bas-reliefs from modified polystyrene foam.

Thanks to technological progress and human ingenuity, the heavy becomes easy, the complex becomes simple, and what was art that only a select few could do, today everyone can perform at their own dacha. If the question arose of finishing and warming the facade of a stone house, you can choose the described method and a simple country house will turn into an exquisite mansion of the Baroque era.

Is there a reason why the second method of creating a massive rusticated facade is considered modern?

The second method of creating a massive rusticated facade is considered modern due to several factors. Firstly, it involves the use of contemporary construction techniques and materials, which are more advanced than those used in traditional methods. This allows for greater precision and efficiency in creating the facade.

Additionally, the second method often incorporates innovative design elements and technologies that enhance the aesthetic appeal and functionality of the rusticated facade. These can include features such as energy-efficient systems, integrated smart technology, and sustainable materials.

Furthermore, the second method of creating a massive rusticated facade is often associated with a more minimalist and streamlined architectural style, which resonates with modern design principles. It embraces simplicity, clean lines, and a focus on functionality, distinguishing it from the more ornate and elaborate techniques utilized in traditional methods.

Ultimately, the modernity of the second method lies in its combination of advanced construction techniques, innovative design elements, and a minimalist aesthetic, all of which contribute to its recognition as a contemporary approach to rusticated facades.

The second method of creating a massive rusticated facade is considered modern because it employs contemporary techniques and materials. Unlike traditional methods that involve hand carving or using natural stone, the modern approach utilizes machinery and precast concrete panels. This allows for efficient and precise construction, resulting in a consistent and uniform appearance. Additionally, the use of concrete provides durability and resistance to weathering, making it a practical choice for long-term maintenance. Overall, the combination of advanced construction methods and durable materials makes the second method of creating a massive rusticated facade a modern and efficient approach.

This statement caught my attention, but I would like to know more about the different methods of creating a rusticated facade. Could you please provide more information about the first method and explain how it differs from the modern approach mentioned?

What specific techniques or materials are used in the modern method of creating a massive rusticated facade?

The modern method of creating a massive rusticated facade involves the use of various techniques and materials. One common technique is the application of a textured finish, such as roughcasting or pebble-dash, to the exterior surface of the building. This involves mixing cement, sand, and small pebbles or stones, which is then applied to the surface and left to harden. Another technique is the use of faux finishes, where the facade is painted or stained to achieve a rusticated look. This technique often involves the use of specialized paint or stain products that mimic the appearance of aged or weathered stone. In terms of materials, modern rusticated facades can be made from a variety of substances, including brick, stone, and concrete. These materials can be specially treated or textured to achieve the desired rustic appearance, such as through acid washing or sandblasting. Overall, the modern method of creating a massive rusticated facade involves combining these various techniques and materials to achieve a visually striking and textured exterior.