The abbreviation LVL comes from the English Laminated Veneer Lumber, that is, “laminated veneer lumber”. This fully meets the material manufacturing technology:

- first, prepared coniferous logs are cleared of bark;

- then the wood is soaked for a day, sometimes for a longer period;

- then chocks are cut from the logs and veneer is made 3 mm thick;

- veneer is sorted and dried;

- veneer layers are glued together, the resulting timber is pressed, cut, marked.

The production process is automated; a computer program is responsible for peeling, centering, measuring the workpieces, and the quality of the veneer is checked by ultrasound. LVL can not be produced handicraft, only in large-scale industries. In our country, the material is produced under the Ultralam brand.

As you can see, the production process is similar to the creation of conventional plywood. The main difference is that in LVL, the fibers of adjacent wood layers are arranged parallel. One timber can contain 7-9 veneer layers. The thinnest bar or LVL layer is 18 mm thick, the thickest – 102 mm. The width can vary in the range of 100 – 1800 mm, and the maximum length of the cant is 18 m. Such a wide range of sizes expands the possibilities of using LVL beams in construction.

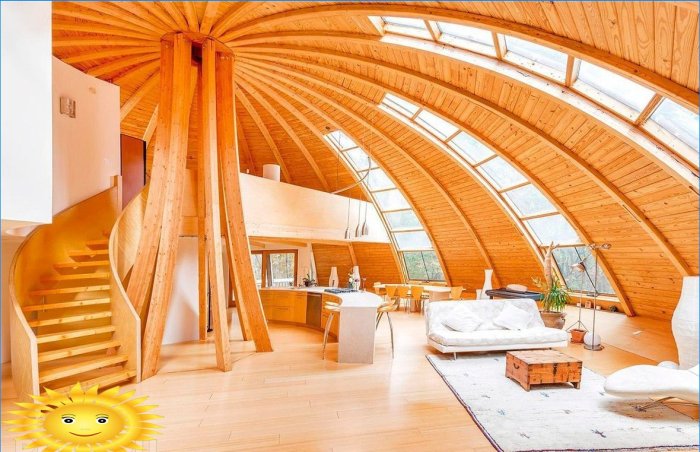

We briefly touched upon the use of LVL timber when we wrote about the choice of material for building a house. Most often, LVL beams are used in the following areas:

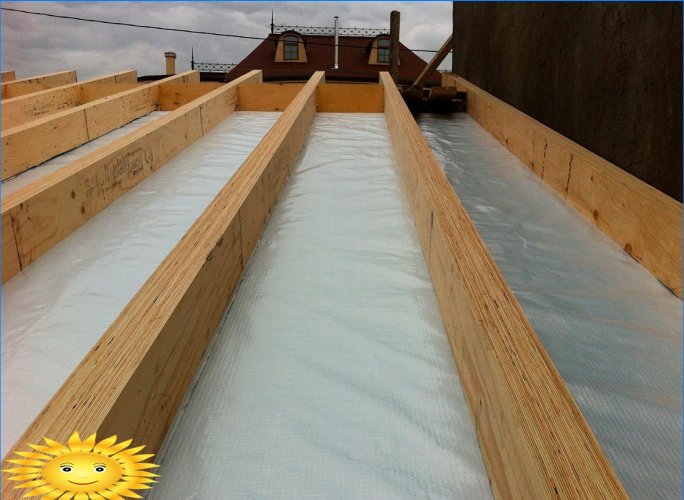

- as interfloor beams;

- rafter legs;

- ridge beams;

- creating large spans;

- in power formwork systems.

Since LVL is not afraid of moisture and aggressive environment, it is often used in the construction of indoor swimming pools, baths and saunas, agricultural buildings and warehouses.

In addition, the material can be used as lintels for doors and windows, become the basis for facade glazing, and be used in the construction of stairs..

Among the characteristics of LVL, which make it a popular building material, it should be noted:

- tensile and flexural strength along the grain is twice that of other sawn timber;

- LVL timber does not support combustion, smolders and gradually fades away;

- not afraid of moisture, bio-resistant;

- the structure is homogeneous, geometric dimensions are always accurate;

- does not shrink, does not deform due to temperature and humidity changes;

- good thermal insulation performance;

- there is no risk of detecting wood defects.

There are two disadvantages of LVL timber – low environmental friendliness due to too much adhesive and a high cost – about 35 thousand rubles per cubic meter. This somewhat limits the possibilities of using the material in construction, but for supporting, auxiliary structures, LVL timber is an excellent option..

What are the characteristics, pros, and cons of using LVL (Laminated Veneer Lumber) as a building material?