The content of the article

- Methods of obtaining and using

- Rennet cheese

- How cheeses are made

- How to recognize the presence of rennet

- Rennet cheese

- Where to get the enzyme

- Rennet at home

- How to replace at home

- Is chymosin harmful?

This is a special organic substance that is produced in the stomach of a newborn calf. It contributes to the stable natural fermentation of dairy products in the production of dairy products. Rennet for cheese gives the product a special delicate taste, dense texture. Coagulation and splitting of dairy products with a natural component occurs in special tightly closed vats, where the external environment will not be able to disrupt the process. Rennet was widely used in the production of cheese varieties:

Methods of obtaining and using

Factory production of rennet in large quantities is impossible due to the characteristics of the process. For the manufacture of this substance, fresh abomasum (stomach) extracted from the body of a slaughtered calf is inflated with air, closed at both ends and subjected to a drying process. The product obtained at the final stage is a white solid powder, which can be purchased for home use in some extended-range pharmacies. Natural rennet is an expensive process due to its low product yield..

Artificial production of microbial mass for fermentation is possible when mold bacteria and fungi of the species mucor, rhizomucor, endothia parasitica are used in the technological process. Replacing the natural product with a non-animal substance makes the use of cheese varieties obtained with its use acceptable for vegetarians. Biotechnology for the manufacture of an active substance that starts and accelerates fermentation has come out much cheaper than the natural method of production, which reduced the cost of rennet cheese without losing their quality.

Rennet cheese

When choosing dairy products that do not contain chymosin, pay attention to the labeling. A substance of natural origin is successfully replaced by rennin during the production of curds, cottage cheese, and cheese. It affects protein in milk according to the same principle as natural abomasum, but it is obtained in a more humane way. The natural enzyme for the preparation of cheese among vegetarians is considered intolerable. Many manufacturers of domestic and imported products do not replace abomasum with rennin, as they write on the labels:

- Parmesan;

- Cheddar;

- Maasdam;

- emmental;

- Roquefort;

- Adyghe;

- feta;

- suluguni.

How cheeses are made

Factory and home cooking of real rennet cheese differs only in production volumes, the possible addition of artificial preservatives, dyes, flavorings at different stages of the technological process. Check out the detailed description of how to make a quality cheese product using abomasum:

- For the manufacture of milk they take with a mass fraction of fat of at least 3.2%, expressed in cows whose feed base was potatoes, corn, carrots, and other root crops with a high calcium content.

- The first stage of production is the maturation of milk, which is kept at a temperature of 8-12 degrees for 12-24 hours. This leads to activation of microflora, increasing the acidity of the product, dissolving calcium salts.

- The second stage is the normalization of fat balance. Depending on the fat content of the cheese variety being produced, cream or skim milk is added to the total volume of liquid to bring the mass fraction of fat to the desired value.

- Pasteurization kills all unnecessary forms of microorganisms that can interfere with or change the process of further fermentation of the product.

- Preparing for coagulation. At this stage, add all the missing spices, flavors, stabilizers and preservatives that should be present in the finished cheese. To improve the fermentation process, calcium chloride is introduced, which accelerates the precipitation of salts.

- Coagulation. The most important step is when the rennet pepsin gradually separates the solid fractions of the dairy product from the whey. The process proceeds at a natural temperature for it of 28-36 degrees and constant stirring of the mass.

- The formation of cheese grains. Using special knives, the mass obtained in the previous step is gradually cut, separated from the serum. Next, the clot is stirred, raising the temperature to 20 degrees, which contributes to giving the grains a rounded shape, removing the remaining liquid fractions.

- Pressing. Remove the last remaining serum. A clot consisting of cheese grains is pressed using special plates on pneumatic pistons. Several times the mass is turned over every 5-10 minutes for self-pressing. The final stage is the moment when moisture ceases to be released from the clot.

- The age of cheese has a direct impact on the taste and chemical composition of the product. During ripening, complex biochemical reactions continue, caused by exposure to pepsin (from rennet) or rennin. Maturation occurs in moist, cool rooms. Once every 2-3 weeks, the head of the cheese must be washed out of excess microorganisms on the surface and turned over to give the correct shape.

- Pack the finished product in plywood or wooden dry boxes. Also, for long-term storage, the use of special thick food packaging is allowed, from which air is completely aspirated.

How to recognize the presence of rennet

For various reasons, eating rennet cheese is undesirable for some people. An example is strict vegetarians who completely abandoned animal food for ideological reasons. Recognizing the presence of natural abomasum in a fermented milk product by external signs is not possible, since it does not affect the taste, smell, color of the product. For recognition of vegetarian and standard food, the designation that the manufacturer puts on the label is used. The presence of the following marks indicates the presence of chymosin in the product:

- rennet extract;

- rennin;

- animal chymosin;

- kalase;

- stabo-1290;

- abomin;

- sweet milk cheese.

Rennet cheese

According to ideological convictions, vegetarians should not eat fermented milk products containing natural abomasum, for which newborn calves and lambs are slaughtered – this enzyme is responsible for digesting mother’s milk. Genetic engineering at the current stage of development does not have the means to reproduce plant copies of the active substance. A completely safe alternative is chymosin derived from special molds and microbial rennin. Check out the list of cheese varieties whose producers don’t use abomasum:

- vegetarian modification of the Adyghe variety;

- feta, TM Denmax;

- Lazur, Polish blue cheese;

- Belebeevsky;

- Caserei Champignon;

- sour cream varieties;

- brand of processed President cheese;

- Lambert;

- Valio.

Where to get the enzyme

Natural rennet is a substance that reproduces the fourth section of the stomach of newborn calves and lambs, for efficient and quick processing of milk, which is divided into components. Owners of their own farms are able to separate the abomasum on their own when slaughtering, fill it with air and dress it to obtain a dry concentrate. Otherwise, the active substance can be found on the shelves of some pharmacies with an extended range. The products of the following manufacturers meet the required quality standards and are commercially available:

- Meiton;

- VIVO Sourdough;

- Squash;

- BK-Uglich;

- Live Balance;

- Lactofarm ECO.

Rennet at home

Making the right rennet cheese is not possible without a quality base for the starter culture. At home, you can independently obtain the desired active substance, called abomasum. For this you need a carcass or stomach of an animal slaughtered no later than twelve hours ago. Follow a certain procedure to get high-quality abomasum suitable for fermentation:

- Separate the stomach (abomasum) from the carcass of a recently slaughtered animal.

- Rinse thoroughly with cool running water from the outside and inside without the use of cleaning products, abrasive materials, sponges, rags.

- Tie one hole tightly with twine or twine. Tie the abomasum through the second filler with air, tie until tight.

- Hang in a dry, warm room. Readiness can be determined by the structure of the tissues of the stomach: they should become like parchment paper.

- Grind the finished abomasum to the consistency of the powder or break off the pieces to prepare the starter culture at the rate of 5 grams of the finished product per 1 liter of milk.

How to replace at home

For the production of fermented milk products at home by fermentation, the use of substances of plant origin is allowed to help form a full-fledged sourdough. The berries used to activate the fermentation process in homemade wines are also great for fermenting dairy products. The following replacement options are considered the most successful:

- Freshly squeezed fig juice without cake.

- Special starter grass.

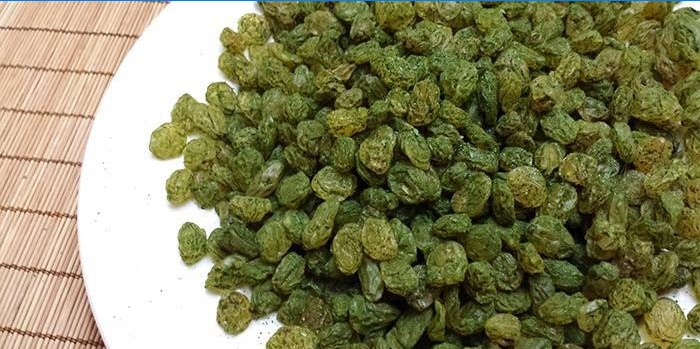

- Dried green unwashed grapes.

- A decoction of homemade nettle paste with salt.

- Ready-made starter cultures from molds, dehydrated bacteria.

Is chymosin harmful?

Most natural products are much more useful than their artificial counterparts, with which they are gradually trying to replace them in order to reduce the cost of production. The same trend is observed in the field of cheese making. Natural rennet is difficult to obtain, and processes involving it automatically become very expensive. But does it make sense to replace natural abomasum with factory analogues in terms of impact on the consumer’s body? Consider the features of such a replacement:

- Change in the natural processes of cheese making. When using artificial analogues of chymosin, the fermentation of milk is greatly accelerated, which leads to an increase in the mass fraction of phosphates in the finished product. Their use contributes to the leaching of calcium from human bones, which makes them more fragile, brittle, incapable of regeneration..

- Natural help to the stomach. Chymosin is also produced by the human body, being for him a natural enzyme. The substance itself, when ingested, will not cause any damage. Instead, the consumer will temporarily speed up digestion, improve bowel function.

- Improvement of natural properties. Scientists in Italy have been working for a decade to create artificially synthesized chymosin specifically for cheese making. Its difference from the natural one is to increase efficiency by 50-60% while preserving the remaining beneficial properties exerted on the human body.

What is the difference between animal and synthetic rennet? Can I easily make my own rennet at home? What are the preferred methods for producing rennet?

What exactly is rennet and how is it produced? I’m particularly interested in learning about both the animal and synthetic methods for producing it. Additionally, I would like to know if it’s possible to make rennet at home. Can anyone provide some insights on these topics? Thanks in advance!

Rennet is an enzyme complex primarily used in cheesemaking to coagulate milk and separate it into curds and whey. Traditionally, rennet is sourced from the stomach lining of young ruminant animals, such as calves, lambs, or goats, as it naturally contains the enzyme chymosin. After slaughter, the stomachs are collected, cleaned, and dried before being sliced and steeped in a brine solution to extract the rennet. This animal-based rennet is preferred by traditional cheesemakers for its ability to produce high-quality cheese.

Synthetic rennet, also known as microbial rennet, is a vegetarian alternative. It is produced through genetic engineering, where specific microorganisms, such as bacteria or fungi, are modified to produce chymosin. The resulting enzymes are then extracted and purified for commercial use. Synthetic rennet is widely used today, especially in industrial cheese production or by those adhering to vegetarian or religious dietary restrictions.

Making rennet at home is possible using an animal-based method but involves ethical considerations. Some home cheesemakers use rennet from young animals sourced from local farms or seek alternatives sourced from animals raised under specific conditions. Besides, vegetarian cheesemakers can opt for plant-based rennet substitutes like nettles, thistles, or fermented sources. These substitutes, while not identical to traditional rennet, can still coagulate milk and facilitate homemade cheesemaking.

Rennet is a crucial ingredient in cheesemaking, as it helps milk coagulate into curds for cheese production. Traditional rennet is derived from the stomach lining of young ruminant animals, containing the enzyme chymosin. However, vegetarian-friendly options like synthetic rennet produced through genetic engineering are available. Home cheesemakers can make ethical choices by sourcing rennet from animals raised under specific conditions or using plant-based alternatives like nettles or thistles. While traditional rennet is preferred for its quality, these substitutes can still be used to create homemade cheese.